Vers. 291020 2

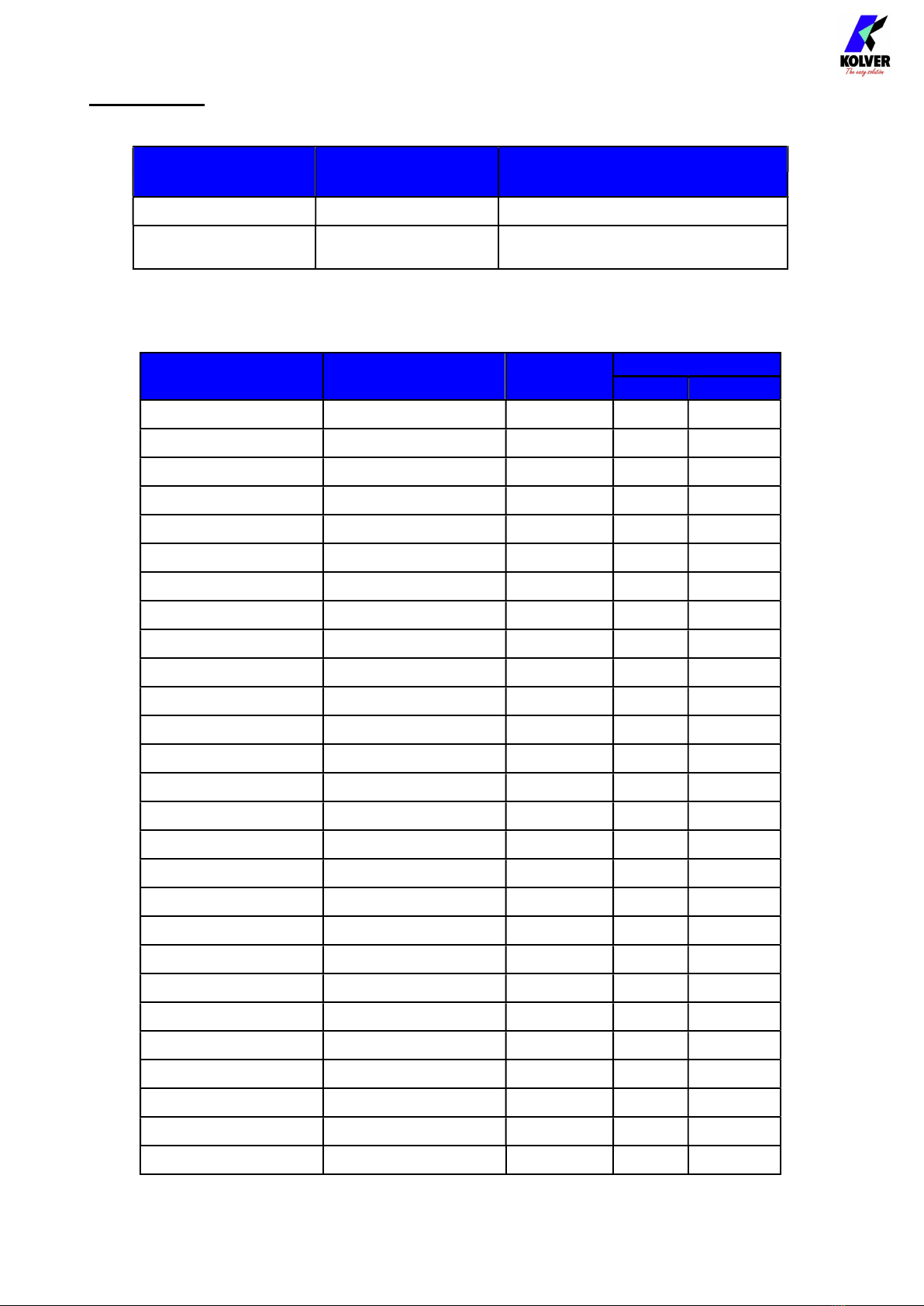

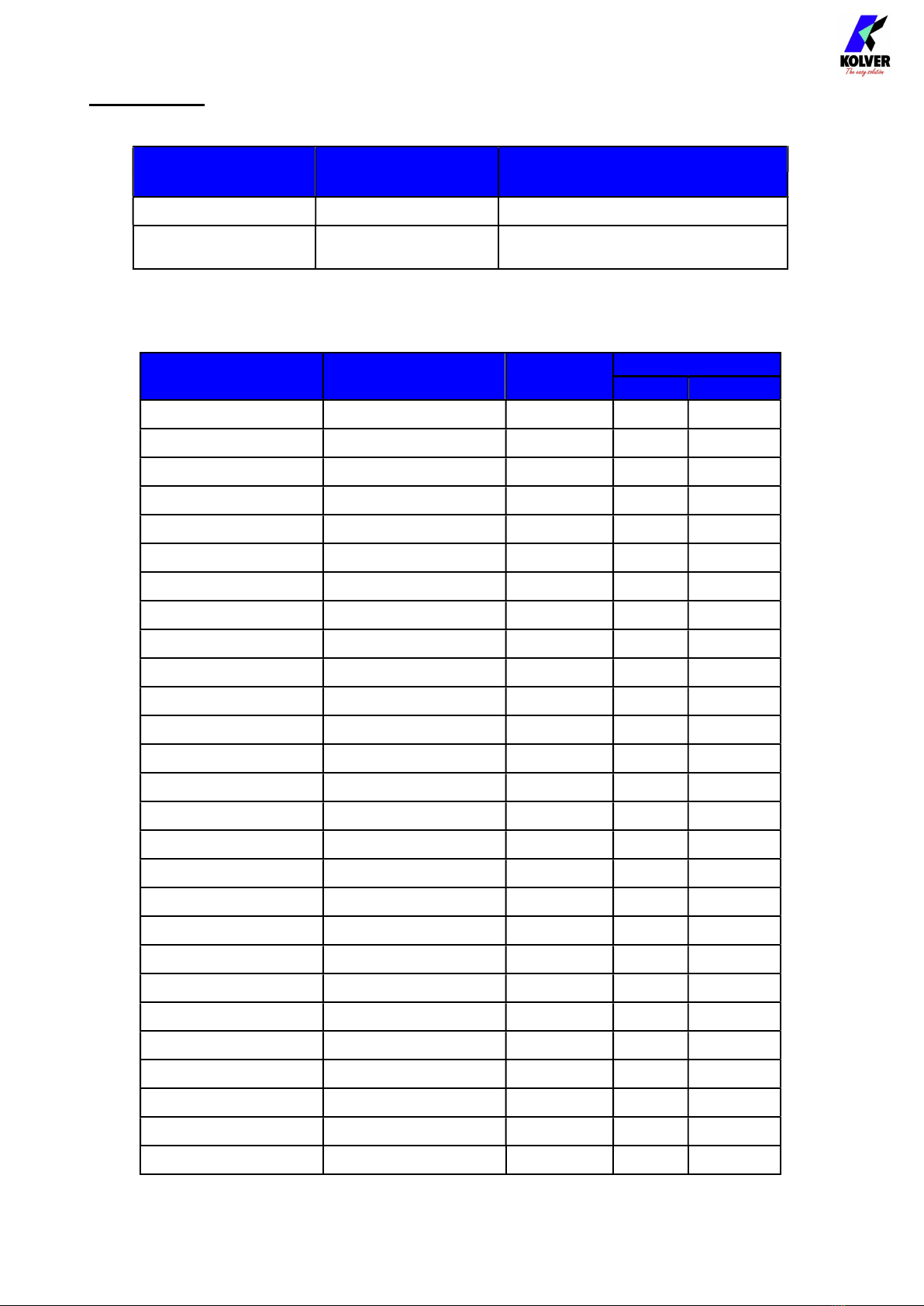

MODELS:

K-DUCER power supply and control units are available in two versions:

Code Model Features

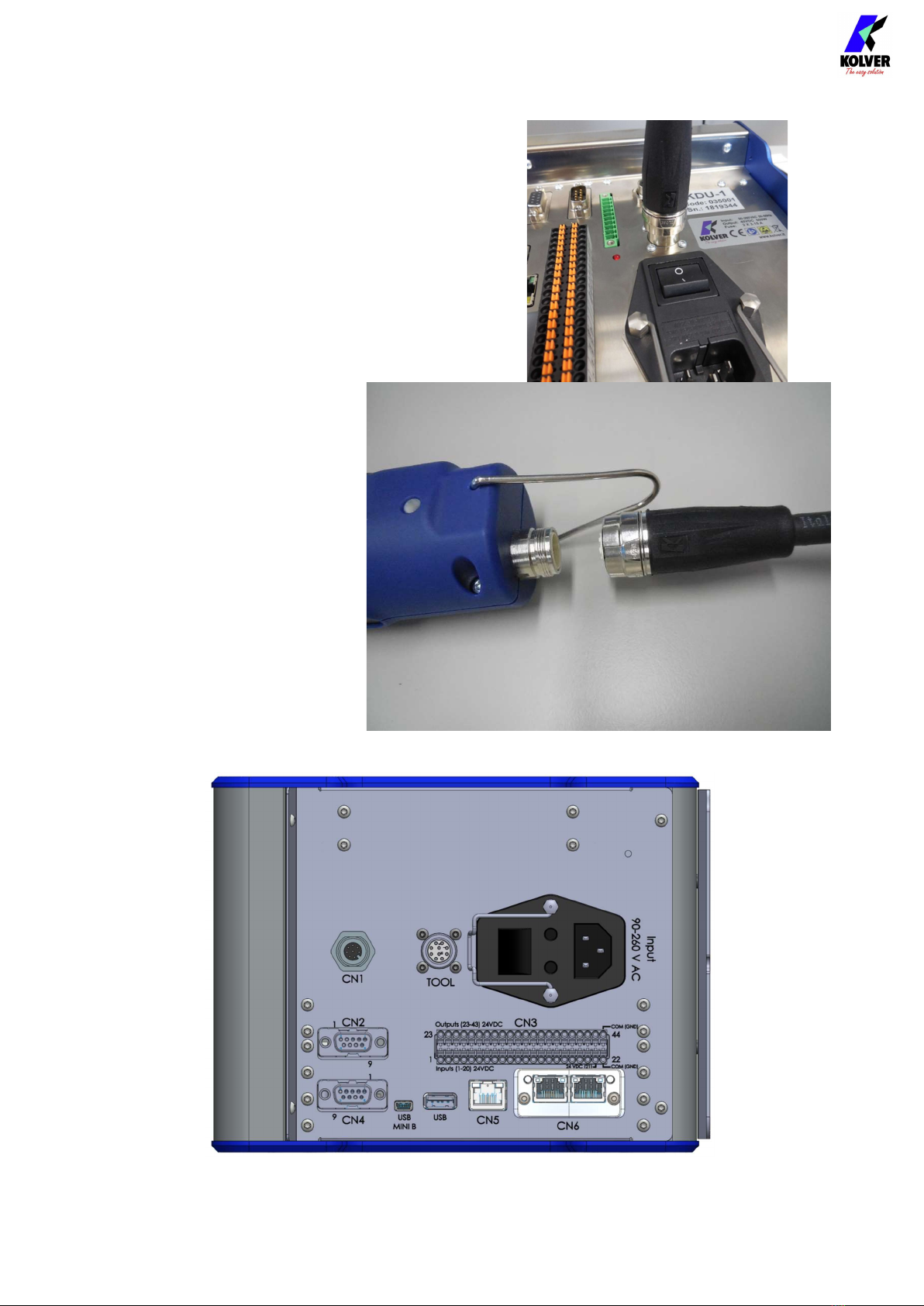

035001 KDU-1

035001/A KDU-1A as KDU-1 + RJ4 connector

Modbus TCP (slave) communication protocol

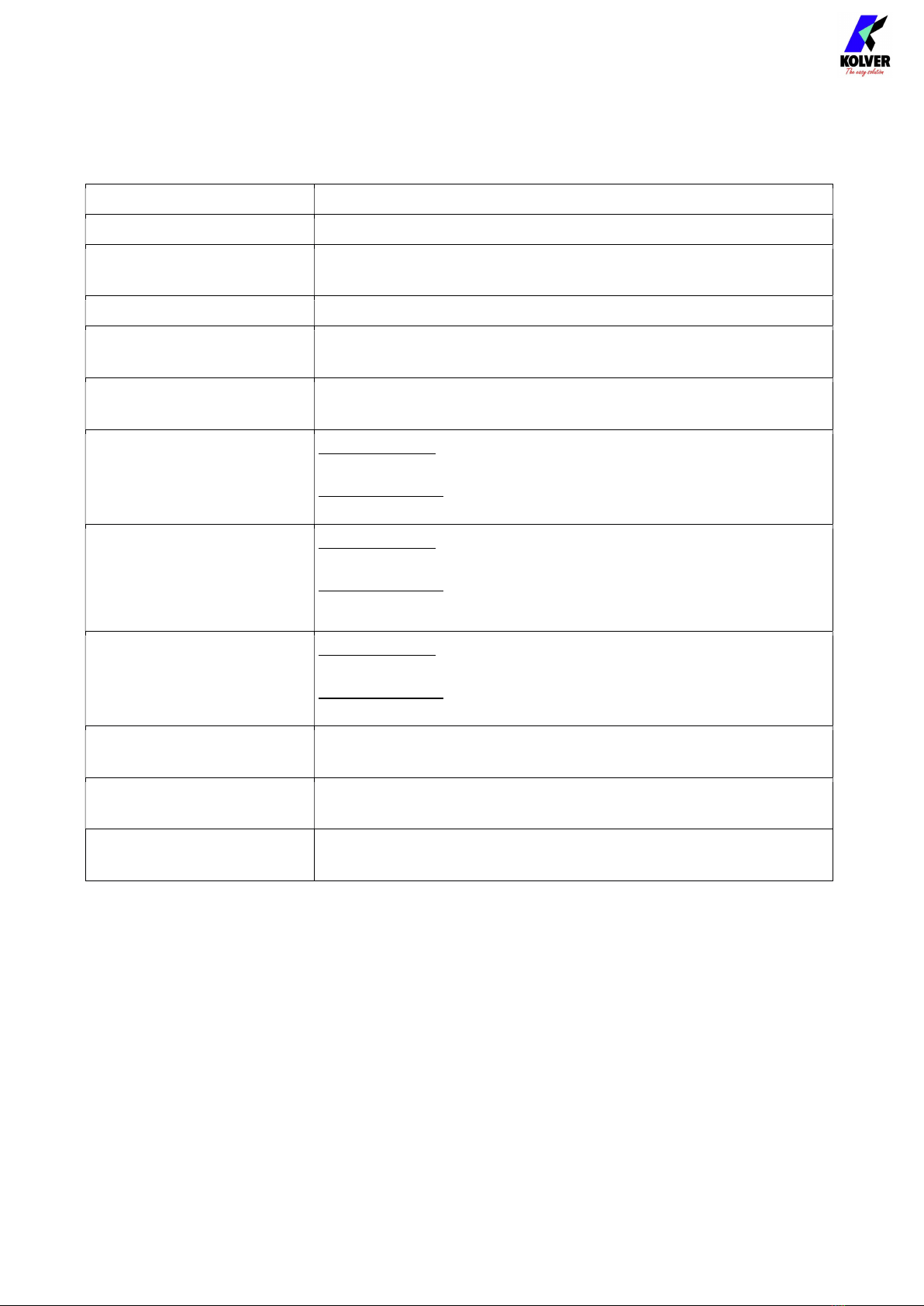

They also control the torque of any KDS electric screwdrivers with transducer, available straight, pistol

and fixture configuration.

Code Model Torque (Nm)

Speed (rpm)

Min

Max

135006 KDS-PL6 0,5-6 50 850

135006/ESD KDS-PL6 0,5-6 50 850

135007/ESD KDS-PL6P 0,5-6 50 850

135007/U/ESD KDS-PL6P/U 0,5-6 50 850

135106 KDS-PL6CA 0,5-6 50 850

135106/FN KDS-PL6CA/FN 0,5-6 50 850

135006/A/ESD KDS-PL6ANG 0,5-5,5 50 850

135010 KDS-PL10 0,8-10 50 600

135010/ESD KDS-PL10 0,8-10 50 600

135011/ESD KDS-PL10P 0,8-10 50 600

135011/U/ESD KDS-PL10P/U 0,8-10 50 600

135110 KDS-PL10CA 0,8-10 50 600

135110/FN KDS-PL10CA/FN 0,8-10 50 600

135010/A/ESD KDS-PL10ANG 0,8-9 50 600

135015 KDS-PL15 0,5-15 50 320

135015/ESD KDS-PL15 0,5-15 50 320

135016/ESD KDS-PL15P 0,5-15 50 320

135016/U/ESD KDS-PL15P/U 0,5-15 50 320

135115 KDS-PL15CA 0,5-15 50 320

135115/FN KDS-PL15CA/FN 0,5-15 50 320

135015/A/ESD KDS-PL15ANG 0,5-14 50 320

175015 KDS-MT1.5 0,1-1,5 50 850

175015/ESD KDS-MT1.5/ESD 0,1-1,5 50 850

175016/ESD KDS-MT1.5P 0,1-1,5 50 850

175016/U/ESD KDS-MT1.5P/U 0,1-1,5 50 850

175115 KDS-MT1.5CA 0,1-1,5 50 850

175115/FN KDS-MT1.5CA/FN 0,1-1,5 50 850