EDU1AE power supply and control unit is an innovative system for controlling the torque

of both our PLUTO10 and PLUTO15 electric screwdrivers either inline, pistol or for

automation.

EDU1AE and Pluto delivers all the advantages of precision torque control electric tools at a

fraction of the price of transdurized tools.

The state-of-the-art electronic control circuit cuts the power supply to the motor calculating

the correct torque in response to 3 parameters; voltage, frequency and current, according to

the selected options.

IMPORTANT: EDU1AE controller is a highly accurate unit but it is critically important to

select the correct options to ensure that proper torque is being applied. Read the menu

description carefully and in case you are unsure please contact Kolver for support

information.

Here are a few advantages of EDU1AE:

•One controller only for a torque range from 2 to 15 Nm. On certain joints torque values

between 0.5 and 2 Nm are also possible. Please contact Kolver for additional information.

•User interface screens: walk through a few simple steps to input the parameters requested

for your application and your fastening process can begin.

•Slow start and adjustable speed.

•Soft or hard joint application.

•High speed rundown and slow speed tightening for improved accuracy.

•Automatic reverse at cycle end possible.

•Autostop on elapsed time.

•Torque reached signal, lever signal.

•Start and reverse contacts.

•Remote torque selection possible (please contact Kolver for additional information).

•Low noise level, only 55 dBA, low weight, less than 0.5 kg .

TORQUE RANGE:

PLUTO10:

•HARD programme: max torque 9,80 Nm

•SOFT programme: max torque 8,10 Nm

•S-E (semi-elastic joint K5 and K20): max torque 8,70 Nm

PLUTO15

•HARD programme: max torque 14,70 Nm

•SOFT programme: max torque 13,50 Nm

•S-E (semi-elastic joint K5 and K20): max torque 14,90 Nm

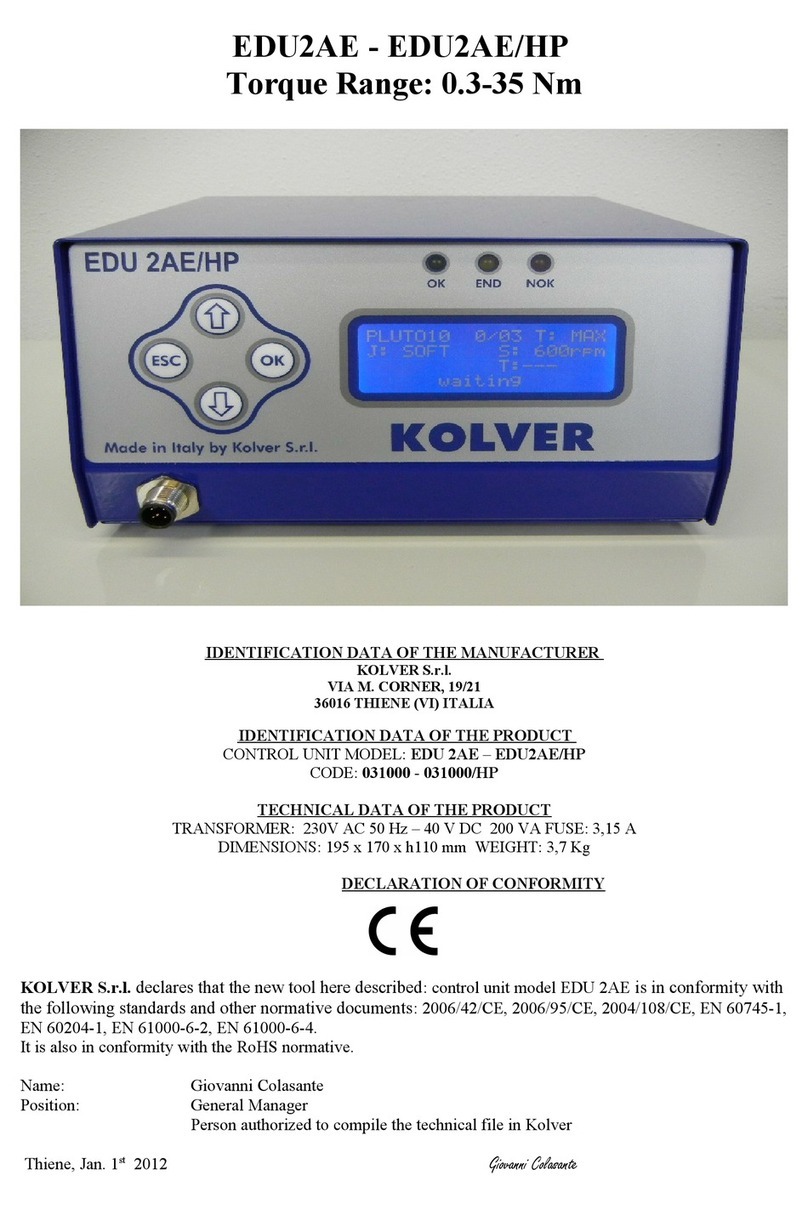

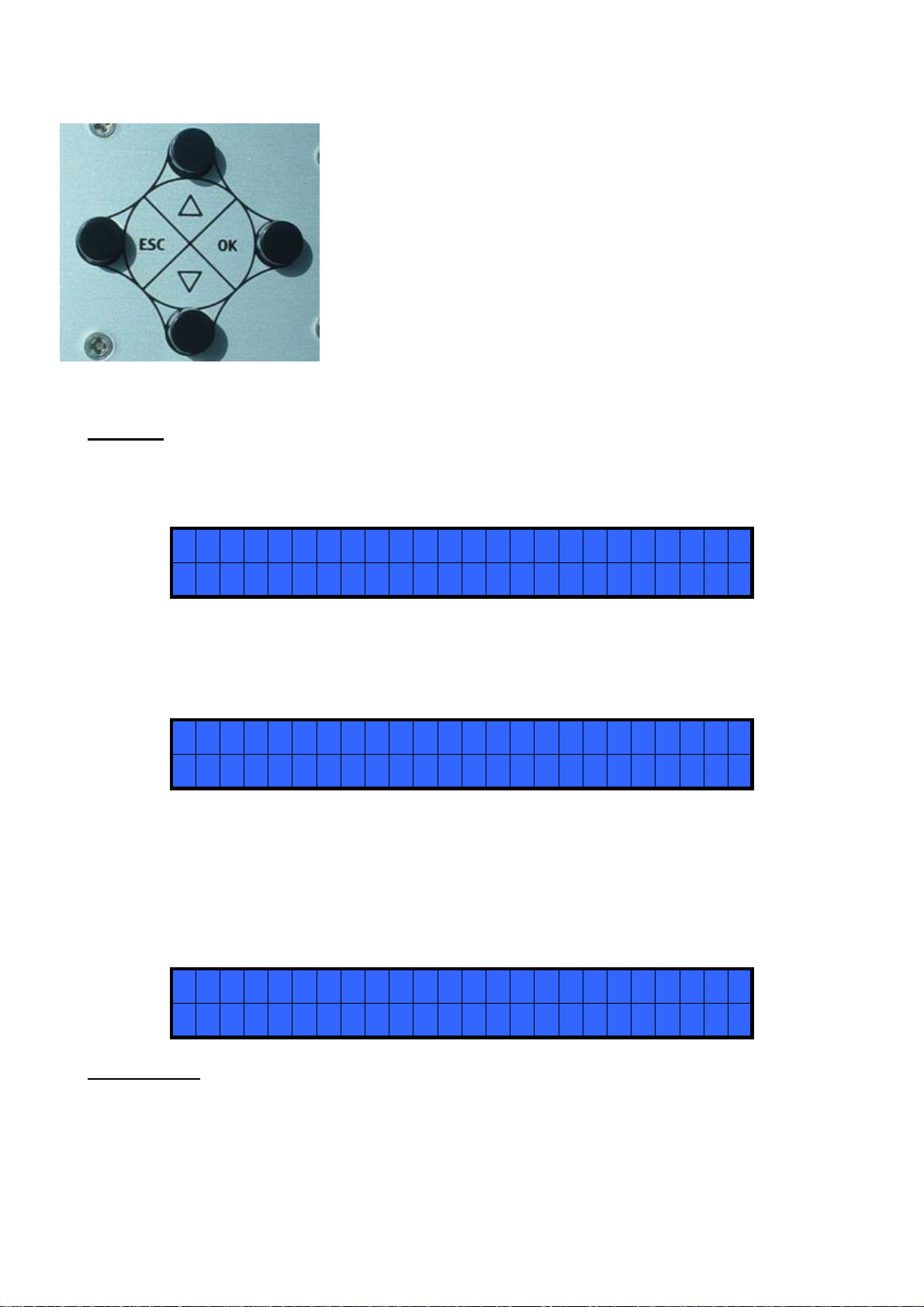

Turn the unit on through the on/off switch on the back panel. The unit will carry a general system

check and then display the main screen indicating the screwdriver model (Pluto10 or 15), the

corresponding torque range (Range: 2-10 or 2-15 Nm), the joint type (J: Hard or J: Soft), the brake

time (Z) and the torque level (Level).

P L UTO1 0 RANGE : 2 . 0 - 1 0 . 0 Nm

J : SOF T Z : - - - - L EVE L : 2 0