Warnings

3A2702A 5

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily

injury. In the event that injection occurs, get immediate surgical treatment.

•Do not aim the gun at, or spray any person or animal.

•Keephandsandotherbody partsawayfromthe discharge.Forexample,donot

try to stop leaks with any part of the body.

•Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

•Use Graco nozzle tips.

•Use caution when cleaning and changing nozzle tips. In the case where the

nozzletipclogswhilespraying,followthePressure Relief Procedure forturning

off the unit and relieving the pressure before removing the nozzle tip to clean.

•Equipment maintains pressure after power is shut off. Do not leave the

equipment energized orunder pressure while unattended. Followthe Pressure

Relief Procedure when the equipment is unattended or not in use, and before

servicing, cleaning, or removing parts.

•Check hoses and parts for signs of damage. Replace any damaged hoses or

parts.

•This system is capable of producing 3000 psi. Use Graco replacement parts or

accessories that are rated a minimum of 3000 psi.

•Always engage the trigger lock when not spraying. Verify the trigger lock is

functioning properly.

•Verify that all connections are secure before operating the unit.

•Knowhowtostoptheunitandbleedpressurequickly.Bethoroughlyfamiliarwith

the controls.

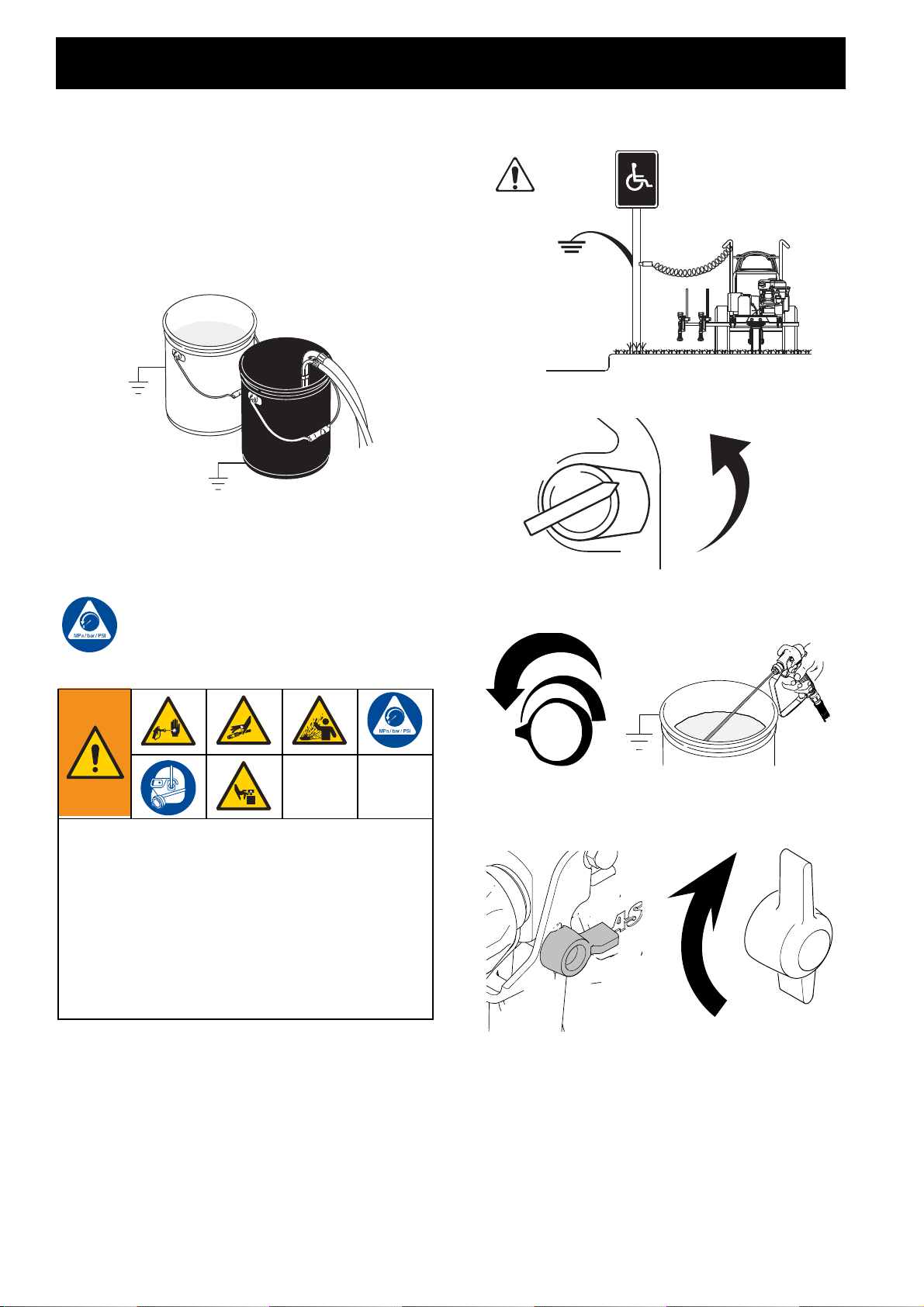

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

•Do not operate the unit when fatigued or under the influence of drugs or alcohol.

•Do not exceed the maximum working pressure or temperature rating of the low-

est rated system component. See Technical Data in all equipment manuals.

•Use fluids and solvents that are compatible with equipment wetted parts. See

Technical Data inallequipmentmanuals.Readfluidandsolventmanufacturer’s

warnings. For complete information about your material, request Safety Data

Sheet (SDS) from distributor or retailer.

•Do not leave the work area while equipment is energized or under pressure.

•Turn off all equipment and follow the Pressure Relief Procedure when equip-

ment is not in use.

•Check equipment daily. Repair or replace worn or damaged parts immediately

with genuine manufacturer’s replacement parts only.

•Do not alter or modify equipment. Alterations or modifications may void agency

approvals and create safety hazards.

•Make sure all equipment is rated and approved for the environment in which you

are using it.

•Use equipment only for its intended purpose. Call your distributor for information.

•Route hoses and cables away from traffic areas, sharp edges,moving parts, and

hot surfaces.

•Do not kink or over bend hoses or use hoses to pull equipment.

•Keep children and animals away from work area.

•Comply with all applicable safety regulations.