Komfovent PPU-LCHX User manual

Pipework package unit for liquid coupled heat exchanger

PPU-LCHX

2UAB KOMFOVENT we reserve the right to make changes without prior notice

PPU-LCHX_21-05

EN

CONTENT

1. INTRODUCTION ...........................................................................................................................................................................................................3

2. ENCODING AND CONSTRUCTION ......................................................................................................................................................................3

3. MECHANICAL INSTALLATION...............................................................................................................................................................................4

4. ELECTRICAL INSTALLATION..................................................................................................................................................................................5

5. FLOW RATE REGULATION .......................................................................................................................................................................................7

6. PERIODICAL MAINTENANCE..............................................................................................................................................................................10

7. TECHNICAL DATA .....................................................................................................................................................................................................10

3

UAB KOMFOVENT we reserve the right to make changes without prior notice

PPU-LCHX_21-05

1. INTRODUCTION

This manual is intended for qualied technicians installing pipework package unit (PPU) for liquid coupled heat exchanger.

Qualied professionals are persons with sucient professional experience and knowledge of plumbing systems for heating/

cooling, their installation, knowledge of electrical safety requirements and ability to work without risk to themselves or others.

To avoid misunderstandings, read this manual carefully before installing the PPU, since ignoring the instructions not only

shall invalidate the manufacturer’s warranty but can also cause direct damage to property or human health.

• When performing installation works, make sure the frequency inverter and circulation pump are

unplugged from electrical supply. Do not connect them to electrical power until all mechanical

works on PPU are nished.

• Use caution when working near internal or external heaters of the airhandling unit (AHU), as

their surfaces may be hot.

• Do not connect frequency inverter and circulation pump to the power supply network if there is

visible damage that occurred during transportation.

• Use appropriate personal protective equipment (gloves, goggles) when installing or repairing

• the PPU.

This sign means that the product may not be disposed of together with your household waste as dened in Directive

(2002/96/EC) and national legislation on the management of WEEE. This product must be disposed of at an appropri-

ate collection point or recycling facility for waste electrical and electronic equipment (WEEE). Improper handling of

this type of waste due to hazardous substances inside electrical and electronic equipment can endanger the environ-

ment and human health. By helping to ensure proper disposal of this product, you will also contribute to the ecient

use of natural resources. For more information on how to dispose of such waste for further recycling, contact your city

authorities, waste management organisations, approved WEEE systems or your household waste management bodies

representatives.

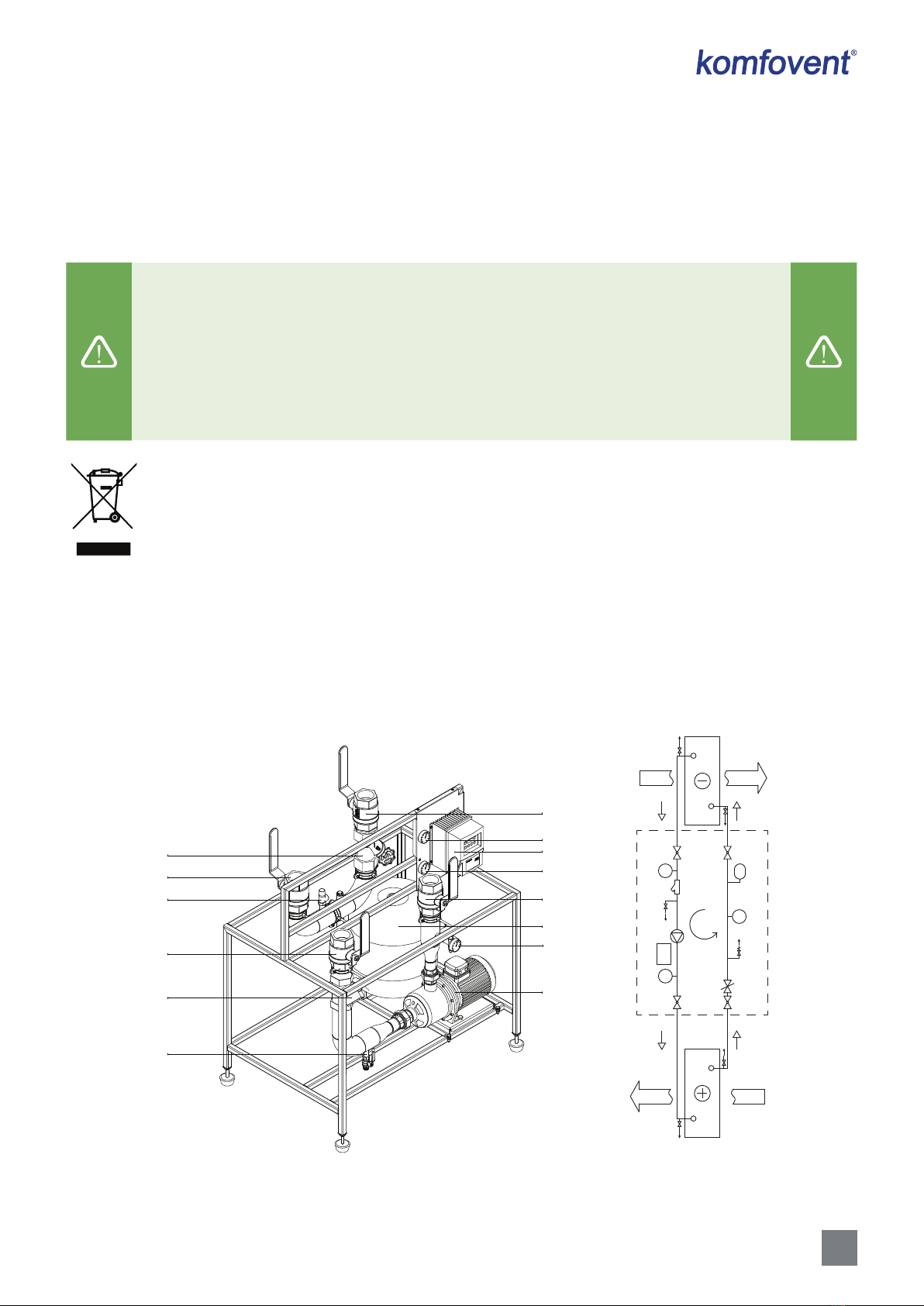

2. ENCODING AND CONSTRUCTION

PPU-LCHX is a pipework package unit for liquid coupled heat exchangers that are used for heat/cold recovery in the air

handling units (AHU). PPU ensures proper circulation of thermal medium (usually mixture of glycol and water) throughout

the piping circuit, regulates requperation eciency and prevents coils from freezing.

1

3

4

6

3

4

2

10

5

4

12

8

4

9

T

T

FC

P

1

3

4

6

3

4

2

10

5

4

12

7

11

8

4

9

Fig. 1. PPU components and hydraulic diagram

1 – Circulation pump; 2 – Frequency inverter; 3 – Thermometer; 4 – Ball valve; 5 – Water lter; 6 – Expansion vessel; 7 – Coil in the supply

airow; 8 – Safety valve; 9 – Drain valve; 10 – Manometer; 11 – Coil in the extract airow; 12 – Balancing valve

4UAB KOMFOVENT we reserve the right to make changes without prior notice

PPU-LCHX_21-05

EN

Encoding:

PPU - LCHX - FQ - L/R - 40 - WG2

123456

1. PPU – Pipework package unit

2. LCHX – Liquid coupled heat exchanger

3. FQ – with frequency inverter

4. L/R – suitable for right (R) and left (L) inspection side AHU’s

5. Connection pipe diameter (DN)

6. Type of circulation pump

3. MECHANICAL INSTALLATION

PPU-LCHX to be installed in technical room, where ambient temperature is 0..+40°C. Unit must be mounted on a at and

sturdy base or on a construction specially designed for mounting. If mounting base ins not at, PPU can be leveled using

adjustable feet at the bottom of the frame.

When selecting mounting location, you must foresee sucient and secure access space for repair

and maintenance operations. Also make sure PPU is not blocking access to the AHU and it’s door can

open freely.

Connect PPU to the heat exchanger coils of the AHU, following hydraulic diagram (see Fig. 1). It is important to ensure

that uid ow direction (marked on the arrow stickers of the PPU) is correct. For eective operation of liquid coupled heat ex-

changer, thermal medium ow direction should be against airow direction. When fully assembled, all hydraulic circuit must

be lled with glycol (not more than 40%) and water mixture. Pipes are lled through the drain valve until static pressure of

1.5bar is reached. Do not use circulation pump of the PPU for lling the pipes – additional equipment or pump must be used.

All piping between PPU and AHU coils should be thermally insulated after the works.

5

UAB KOMFOVENT we reserve the right to make changes without prior notice

PPU-LCHX_21-05

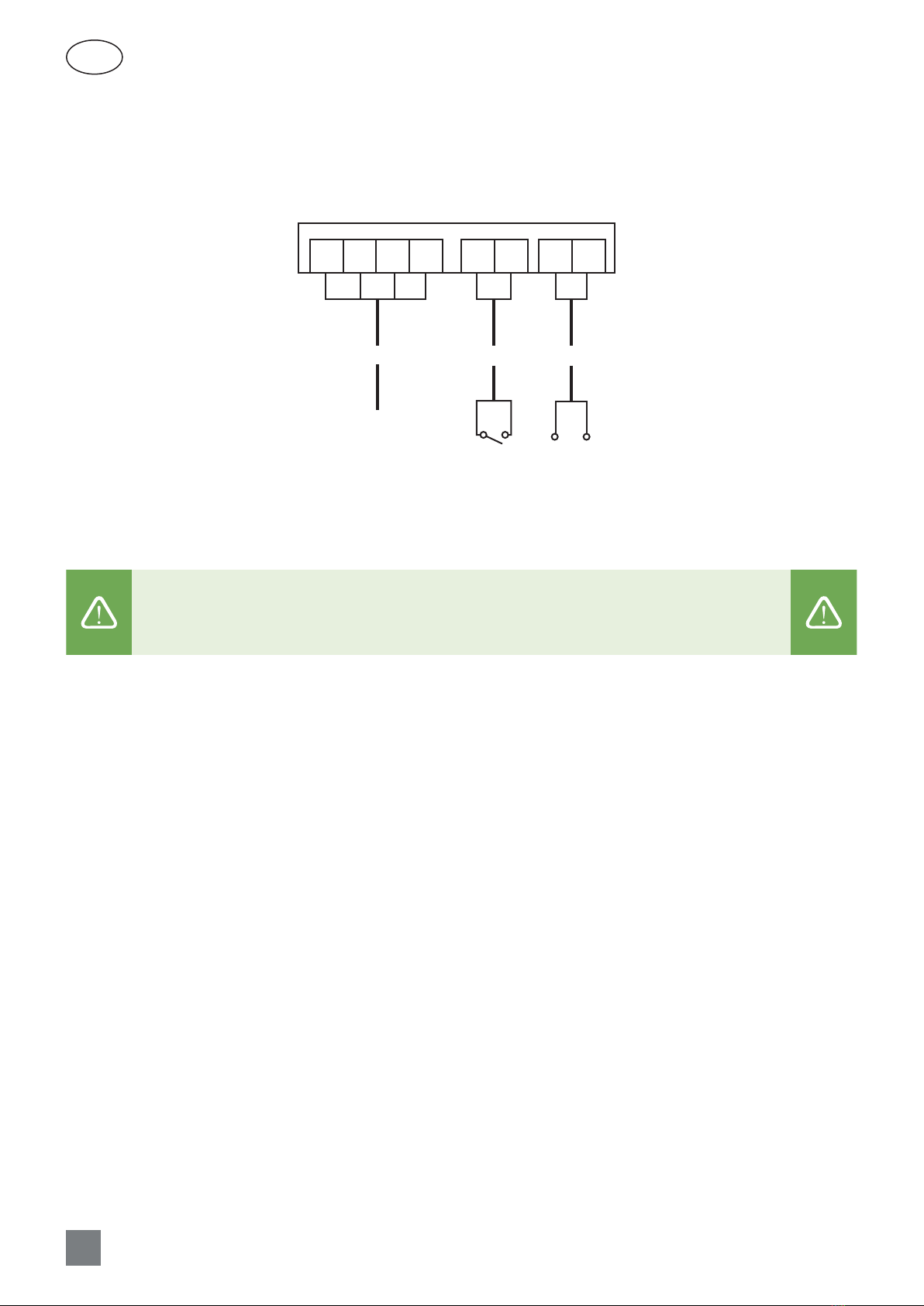

4. ELECTRICAL INSTALLATION

Electrical work may only be carried out by a qualied electrician in accordance with the instructions given in this manual

and in accordance with applicable legal requirements and safety requirements. Before performing electrical component

installation:

• Check there is no mechanical damage on frequency inverter or circulation pump.

• Check the insulation of the cable between frequency inverter and circulation pump is not

damaged.

• Locate user manual for the frequency inverter.

• If the PPU has been standing in an unheated room for a long time, make sure that electronic

parts and cable connectors were not aected by moisture.

Congure micro-switches, connect electrical power and control calbles to the frequency inverter (see Fig. 2):

DIN

10V

AIN

GND

A

B

A

B

COM

NC

U V W PE

PE L1 L2 L3

1

2 3

4

5

OFF ON

1

2

3

5

7

4

6

Fig 2. Frequency inverter

1 – Frequency inverter control terminals, 2 – Pump connection terminals, 3 – Main power terminals

4 – Micro switch conguration, 5 – Control panel connection (RJ9)

6UAB KOMFOVENT we reserve the right to make changes without prior notice

PPU-LCHX_21-05

EN

• Terminals L1, L2, L3, PE are for 3x400 V AC, 50 Hz electrical power connection. Connect power cable to the mains via 10A

automatic circuit breaker (type C).

• Terminals DIN and 10V are for inverter start/stop signal (open/close contact). If such signal is not needed, wire link must

be installed instead.

• Terminals AIN and GND is for inverter control signal (0..10V).

L1 DIN 10V AIN

0..10V DC

GND

COM

3x400V AC

L2 L3 PE

2x0,5mm 2x0,5mm4x1,5mm

Fig. 3. Frequency inverter connection diagram

• Connect the frequency inverter only to suitable power socket with appropriate earthing and

meeting the electrical safety requirements.

• For information on how to connect frequency converter to the AHU automation control, please

follow electrical wiring diagram of the AHU.

7

UAB KOMFOVENT we reserve the right to make changes without prior notice

PPU-LCHX_21-05

5. FLOW RATE REGULATION

For circulation pump to run correctly, it is needed to set PPU ow rate according to designed ow rate stated in the tech-

nical printout of the liquid coupled heat exchanger. Flow rate of the PPU is set as follows:

1. Fully open balancing valve.

2. Connect dierential pressure measuring equipment to the pressure measuring ports of the balancing valve.

3. Using ow rate diagram (Fig. 4), determine which dierential pressure should be achieved, for PPU to reach the de-

signed ow rate.

pressure drop

0,05

0,01

0,01 0,1 1 10 100

100

kv

qmow rate

0,5

5

50

0,05 0,5 5 50

50000

500050050

[dm3/h]

[kPa]

Δp

0,1

10

1

10 100 1000 10000 100000

DN25

DN32

DN40 DN50 DN65

DN20

Fig. 4. Flow rate diagram of the balancing valves

4. Connect control panel of frequency inverter (see Fig. 2).

It is mandatory to turn OFF main power of the inverter, when connecting or disconnecting control

panel cable, otherwise panel will be damaged.

5. Turn ON power of the inverter. Set initial frequency using control panel (20 Hz recommended) and start the inverter:

Output setpoint control, Hz

020.0

1

4

7

2

5

8

0

3

6

9

[1] Operation mode c...

1 - Run

2 - Fire mode

0 - Stop

[1] Operation mode c...

0 - Stop

1 - Run

9 - Analog control

0.0 Hz

Output setp.

0 - Stop

Output freq.

0.0 Hz

Page 1

16:30

0.0 Hz

Output setp.

0 - Stop

Output freq.

0.0 Hz

Page 1

16:30

8UAB KOMFOVENT we reserve the right to make changes without prior notice

PPU-LCHX_21-05

EN

6. By increasing/decreasing inverter frequency, regulate pump speed until correct dierential pressure will be reached.

Memorize or write down operating frequency of the inverter at this pressure point.

20.0 Hz

Output setp.

1 - Run

Output freq.

20.0 Hz

Page 1

16:30

Output setpoint control, Hz

030.0

1

4

7

2

5

8

0

3

6

9

?

7. Stop the inverter:

30.0 Hz

Output setp.

1 - Run

Output freq.

30.0 Hz

Page 1

16:30

[1] Operation mode c...

1 - Run

2 - Fire mode

0 - Stop

[1] Operation mode c...

0 - Stop

1 - Run

9 - Analog control

8. Enter to the parameter 102 same frequency, under which correct dierential pressure was reached (according step 6).

Configuration Op. settings

Overview Motor

Menu

Operation settings

1/ 6

[100] Drive current

limit, %

100 %

[101] Minimum output

freq., Hz

4.0 Hz

[102] Maximum output

freq., Hz

80.0 Hz

[103] Skip frequency 1,

Hz

0.0 Hz

[102] maximum output freq...

030.0

1

4

7

2

5

8

0

3

6

9

0.0 Hz

Output setp.

0 - Stop

Output freq.

0.0 Hz

Page 1

16:30

?

9

UAB KOMFOVENT we reserve the right to make changes without prior notice

PPU-LCHX_21-05

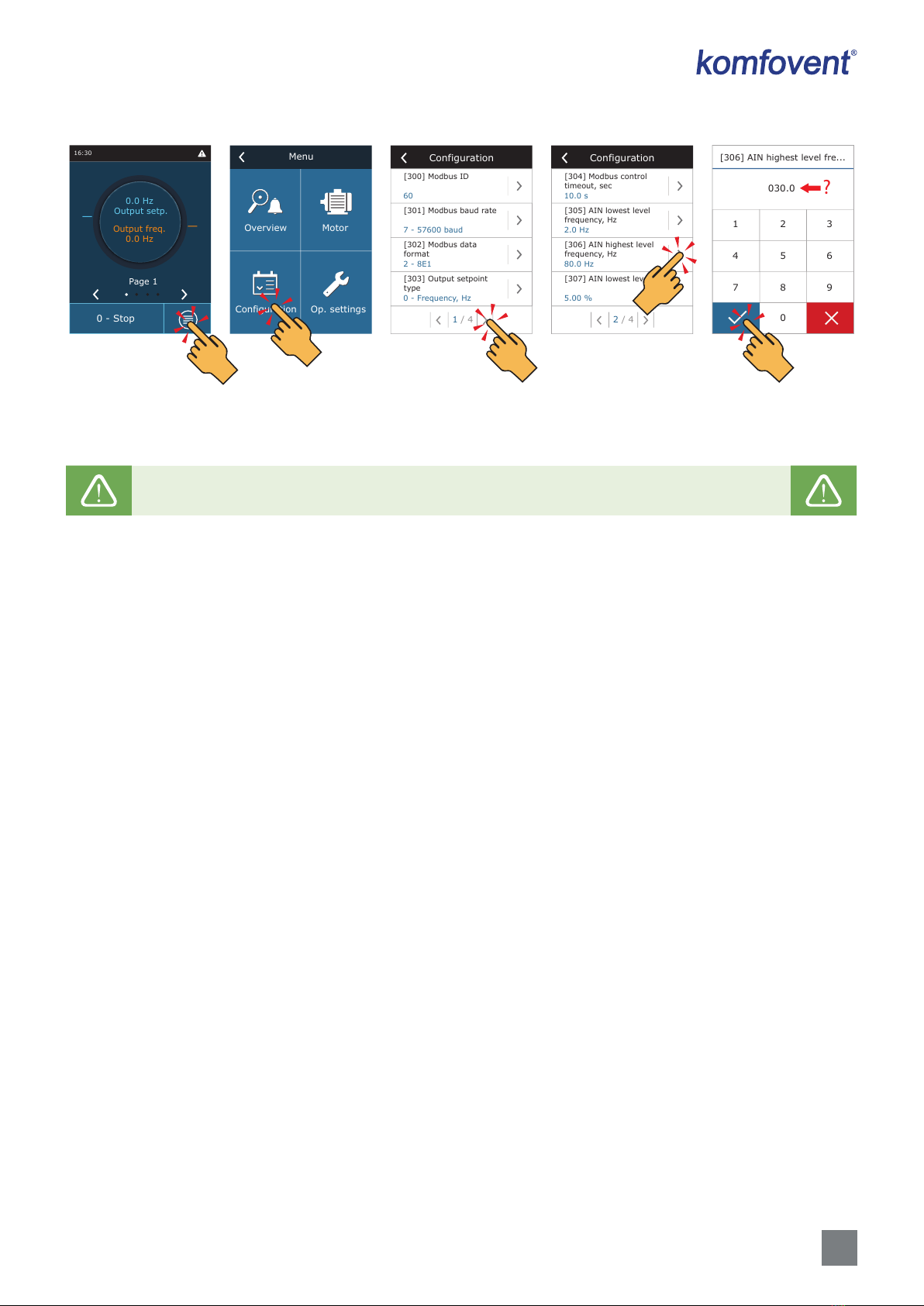

9. Enter to the parameter 306 same frequency, under which correct dierential pressure was reached (according step 6).

Configuration

1/ 4

[300] Modbus ID

60

[301] Modbus baud rate

7 - 57600 baud

[302] Modbus data

format

2 - 8E1

[303] Output setpoint

type

0 - Frequency, Hz

Configuration

2 / 4

[304] Modbus control

timeout, sec

10.0 s

[305] AIN lowest level

frequency, Hz

2.0 Hz

[306] AIN highest level

frequency, Hz

80.0 Hz

[307] AIN lowest level, %

5.00 %

[306] AIN highest level fre...

030.0

1

4

7

2

5

8

0

3

6

9

Configuration Op. settings

Overview Motor

Menu

0.0 Hz

Output setp.

0 - Stop

Output freq.

0.0 Hz

Page 1

16:30

?

10. Turn OFF power of the inverter. If control panel will not be used, disconnect it from the inverter. Also disconnect con-

trol panel in case if PPU is mounted in the unheated room..

It is mandatory to turn OFF main power of the inverter, when connecting or disconnecting control

panel cable, otherwise panel will be damaged.

11. Turn ON main power of the inverter and start AHU. Check operation of the liquid coupled heat exchanger and

PPU-LCHX.

10 UAB KOMFOVENT we reserve the right to make changes without prior notice

PPU-LCHX_21-05

EN

6. PERIODICAL MAINTENANCE

• Before starting any maintenance works, make sure that PPU and AHU are stopped.

• If there is a need to perform any mechanical works on the piping circuit (for example to tighten

couplings or to clean water lter and etc.) disconnect PPU and AHU from the mains power.

It is recommended to carry out PPU-LCHX periodical maintenance at least once a year. If needed register performed

works in the maintenance log.

Following to be checked during maintenance:

• Piping circuit is tight, there are no leakage marks.

• Circulation pump operates correctly. There are no big vibrations or unnecessary noise.

• There are no alarms on the frequency inverter.

• Signal and power cables are in good condition, there are no corrosion marks on the connectors and electrical terminals.

• Measuring tools (manometer, thermometers) operates correctly.

• Water lter is not clogged (clean the lter if necessary).

7. TECHNICAL DATA

Pipework package unit

model

Filter and

balancing

valve

Pipe

connections Pump

type

Pump

power

Frequency inverter

Dimensions of the

PPU frame

(excluding

adjustable feet)

Expansion

vessel

volume

PPU

weight

DN inch kW B,

mm

H,

mm

L,

mm Liters kg

PPU-LCHX-FQ-L/R-20-WG1 DN20 20 3/4” WG1 0,55 DF2-551M0 500 867,5 650 5 45

PPU-LCHX-FQ-L/R-20-WG2 DN20 20 3/4” WG2 0,55 DF2-551M0 500 867,5 650 5 42

PPU-LCHX-FQ-L/R-25-WG1 DN25 25 1” WG1 0,55 DF2-551M0 500 867,5 650 8 46

PPU-LCHX-FQ-L/R-25-WG2 DN25 25 1” WG2 0,55 DF2-551M0 500 867,5 650 8 43

PPU-LCHX-FQ-L/R-32-WG2 DN32 32 1 1/4” WG2 0,55 DF2-551M0 550 867,5 700 12 47

PPU-LCHX-FQ-L/R-40-WG2 DN40 40 1 1/2” WG2 0,55 DF2-551M0 550 1037,5 850 18 60

PPU-LCHX-FQ-L/R-40-WG3 DN40 40 1 1/2” WG3 1,1 DF2-112M0 550 1037,5 850 18 65

PPU-LCHX-FQ-L/R-50-WG3 DN50 50 2” WG3 1,1 DF2-112M0 550 1037,5 900 24 71

PPU-LCHX-FQ-L/R-50-WG4 DN50 50 2” WG4 2,2 DF2-222S0 550 1037,5 900 24 78

PPU-LCHX-FQ-L/R-65-WG3 DN65 65 2 1/2” WG3 1,1 DF2-112M0 670 1037,5 1000 30 75

PPU-LCHX-FQ-L/R-65-WG4 DN65 65 2 1/2” WG4 2,2 DF2-222S0 670 1037,5 1000 30 82

11

UAB KOMFOVENT we reserve the right to make changes without prior notice

PPU-LCHX_21-05

DN20-DN32

BL

42-92

867,5

867,5

DN40-DN65

B L

42-92

1037,5

1037,5

PPU-LCHX_21-05

GERMANY

Komfovent GmbH

Konrad-Zuse-Str. 2a,

42551 Velbert, Deutschland

Tel. +49 0 2051 6051180

info@komfovent.de

www.komfovent.de

LITHUANIA

UAB KOMFOVENT

TECHNINĖS PRIEŽIŪROS SKYRIUS /

SERVICE AND SUPPORT

Phone: +370 5 200 8000

Email: service@komfovent.com

www.komfovent.com

RUSSIA

ООО «КОМФОВЕНТ»

Ул. Выборгская д. 16, стр. 1,

2 этаж, 206 офис, Москва, Россия

Тел. +7 499 673 22 73

www.komfovent.ru

ООО «КОМФОВЕНТ»

Ряжское шоссе, 20 литера Е, пом Н6

390017 г. Рязань, Россия

Тел.: +7 491 255 95 71

www.komfovent.ru

BELARUS

ИООО «Комфовент»

ул. Уручская 21 – 423,

220125 г. Минск, Беларусь

Тел. +375 17 266 5297, 266 6327

www.komfovent.by

SWEDEN

Komfovent AB

Ögärdesvägen 12B

433 30 Partille, Sverige

Tel. +46 31 487 752

info_[email protected]

www.komfovent.se

FINLAND

Komfovent Oy

Muuntotie 1 C1

FI-01 510 Vantaa, Finland

Tel. +358 0 408 263 500

info_@komfovent.com

www.komfovent.com

LATVIA

SIA Komfovent

Bukaišu iela 1, LV-1004 Riga, Latvia

Tel. +371 24 66 4433

info@komfovent.lv

www.komfovent.lv

Vidzemes liāle

Alejas iela 12A, LV-4219 Valmiermuiža,

Valmieras pagasts, Burtnieku novads

Tel. +371 29 358 145

kristaps.[email protected]

www.komfovent.lv

PARTNERS

AT J. PICHLER Gesellschaft m. b. H. www.pichlerluft.at

BE Ventilair group www.ventilairgroup.com

ACB Airconditioning www.acbairco.be

CZ REKUVENT s.r.o. www.rekuvent.cz

CH

WESCO AG www.wesco.ch

SUDCLIMATAIR SA www.sudclimatair.ch

CLIMAIR GmbH www.climair.ch

DK Øland A/S www.oeland.dk

EE BVT Partners www.bvtpartners.ee

FR ATIB www.atib.fr

HR Microclima www.microclima.hr

HU

AIRVENT Légtechnikai Zrt. www.airvent.hu

Gevent Magyarország Kft. www.gevent.hu

Merkapt www.merkapt.hu

IR Fantech Ventilation Ltd www.fantech.ie

IS Blikk & Tækniþjónustan ehf www.bogt.is

Hitataekni ehf www.hitataekni.is

IT Icaria srl www.icariavmc.it

NL

Ventilair group www.ventilairgroup.com

DECIPOL-Vortvent www.vortvent.nl

CLIMA DIRECT BV www.climadirect.com

NO

Ventilution AS www.ventilution.no

Ventistål AS www.ventistal.no

Thermo Control AS www.thermocontrol.no

PL Ventia Sp. z o.o. www.ventia.pl

SE Nordisk Ventilator AB www.nordiskventilator.se

SI Agregat d.o.o www.agregat.si

SK TZB produkt, s.r.o. www.tzbprodukt.sk

Table of contents

Other Komfovent Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Sumitomo Drive Technologies

Sumitomo Drive Technologies PARAMAX SFC Series quick start guide

R.V.R. Elettronica

R.V.R. Elettronica TELINK-SNMP2 user manual

ABB

ABB HT569930 Operation manual

ABB

ABB G391 Series quick start guide

KiloVault

KiloVault HAB Sol-Ark 12K UL9540 installation guide

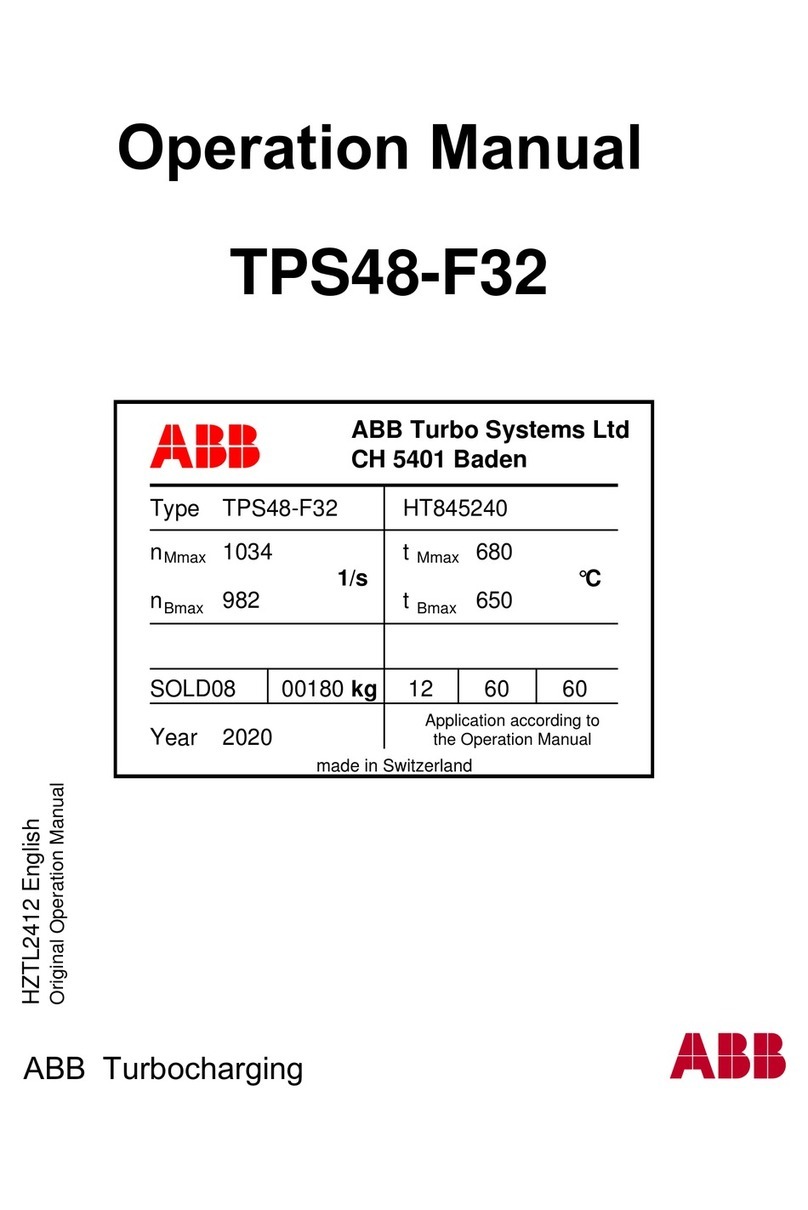

ABB

ABB HT845240 Operation manual