1312

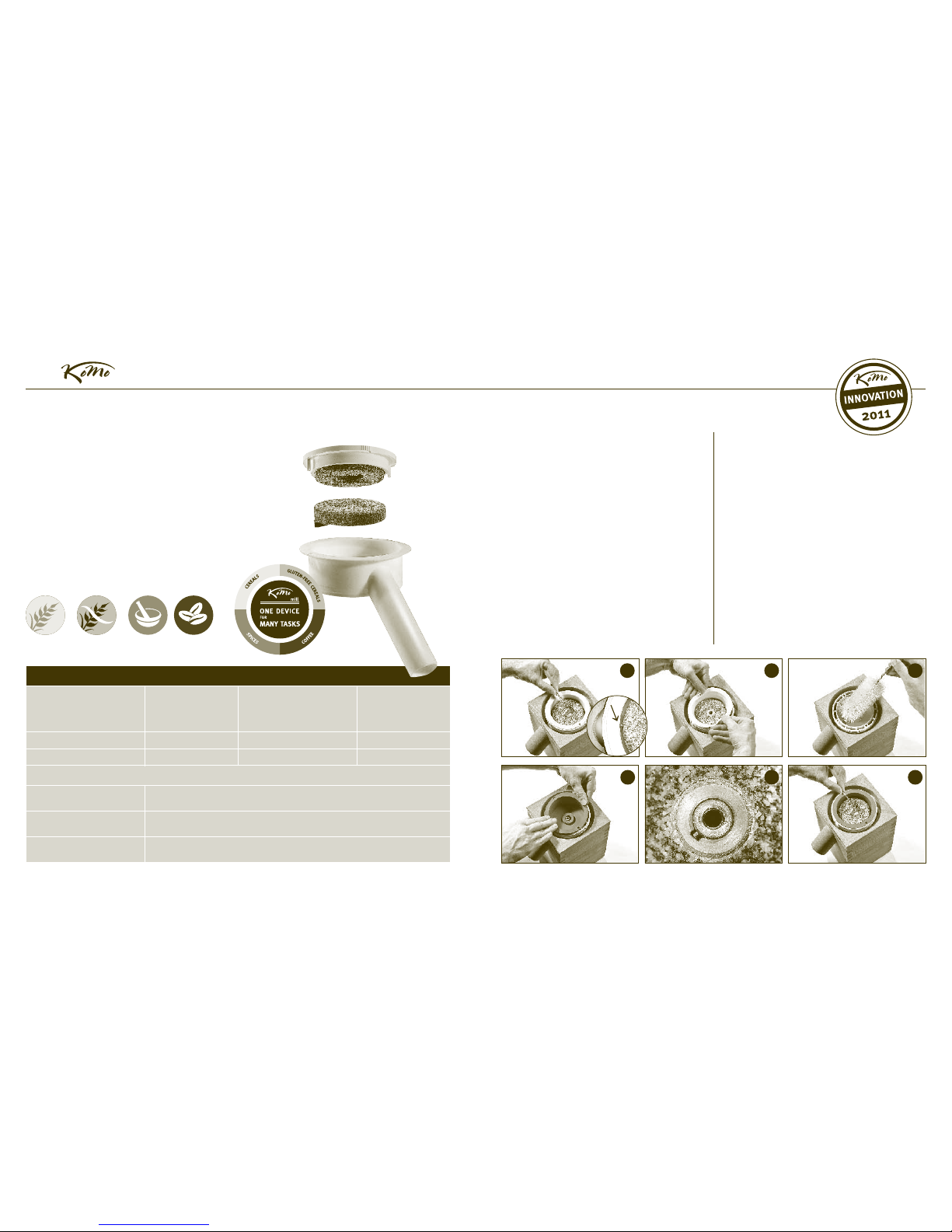

Cleaning the flaker

You can easily clean the flaker. It is best to do

this once a week and immediately after crushing

oilbearing seeds.

Caution: Pull the plug before cleaning!

To clean the flaker, remove the wooden cover by

lifting it up and sliding it forward. To do so, it

is best to grip the cover from the front and to

hold the thumbs on top of the flaker's wooden

body. The cover can then be pushed up using the

fingers. Once the wooden cover is taken off, the

funnel can be removed together with the metal

plate by pulling these forward. Afterwards, the

flaker mechanism can be removed and cleaned.

Simply brush off both rollers, or rinse them under

running water.

With the Flaker 'Duett', the lock screw must be

removed first, before the wood cover, the hopper

and the flaker can be taken out. The required hex

key is provided.

Reassembly of the Flaker

Begin by re-installing the flaker mechanism. Push

the upper plate of the flaker into the lower slots

of the wooden body. Please make sure that the

drive shaft (metal bolt) latches into the notch in-

side the flaker's body. Now slide the mechanism

into the hopper together with the metal plate,

which is aligned with the upper slots of the

wooden body. Then put the wooden cover back

on: insert the brackets (screw heads) for the

wooden cover into the holes and gently push

down on the cover. The correct position of

the panel can be easily checked by gently pull-

ing on it.

During the assembly of the 'Duett'-flaker, two

things need to be observed: First, the hopper

must be positioned correctly after the flaker

mechanism has been reinstalled. Set the hopper

so that its aperture is closer to the front (the

lock screw) and the lower slanted edge is further

to the back (no longer visible after assembly).

Secondly, the wooden cover has sharp edges to

the left and right. Caution! Risk of injury! Position

the panel and hold from below while fastening

the lock screw. The panel is installed correctly

when it is held by the lock screw.

Care

The housings of the KoMo-flakers are made of

beech plywood or solid beech wood which is

treated with organic vegetable oils. The housing

requires no special care, but can be treated with

linseed oil as needed.

Quick Guide

1

Plug in the power cord.

2

Place a bowl underneath the funnel outlet.

3

Pour oats or other grain into the hopper.

4

Switch on the unit to initiate the flaking process.

5

Once the process is finished, switch off the flaker

and unplug the power cord.

Seeds

• Use only thoroughly cleaned grain, free of

stones and other foreign objects.

• Note that only oats and oilseeds (such as flax

seed) can be processed immediately without

special preparation. Other cereals such as wheat,

rye, barley, millet, etc. should be prepared for

the rolling process (read 'Preparing the grain for

flaking').

• Fresh oats should be consumed within 1 - 2

hours following flaking. The flaking process ini-

tiates an oxidation process which reduces their

quality (the flakes become bitter). We recommend

huskless, or 'naked' oats for the best flavor. The

seed of other oats can be damaged during the

peeling process, reducing its quality and eventu-

ally giving the oats a bitter taste.

Preparing the grain for flaking

To prevent the steel rolls of the flaker from shat-

tering dry, brittle grains into small pieces, you

can soften the grains with water before flaking.

By soaking up water, the grain becomes more

elastic, making for better flaking. At the same

time, the moisture enables an enzymatic pro-

cess* that makes the minerals and nutrients in

the grain more readily available for metabolism

in the human body.

*Enzymatic process: the process during which special pro-

teins (enzymes) contribute to conversion processes (i.e. bio-

chemical reactions).

Moistening the grains: In a strainer, hold the

seeds briefly under running water. Then spread

the grains on a cloth or towel to let them dry

overnight or for at least 3 - 4 hours. This time will

vary depending on the grain used, but a little

experimentation will help optimize the process.

The softened grain should flatten nicely into

flakes, similar to commercially available rolled

oats.

Operating the Flaker