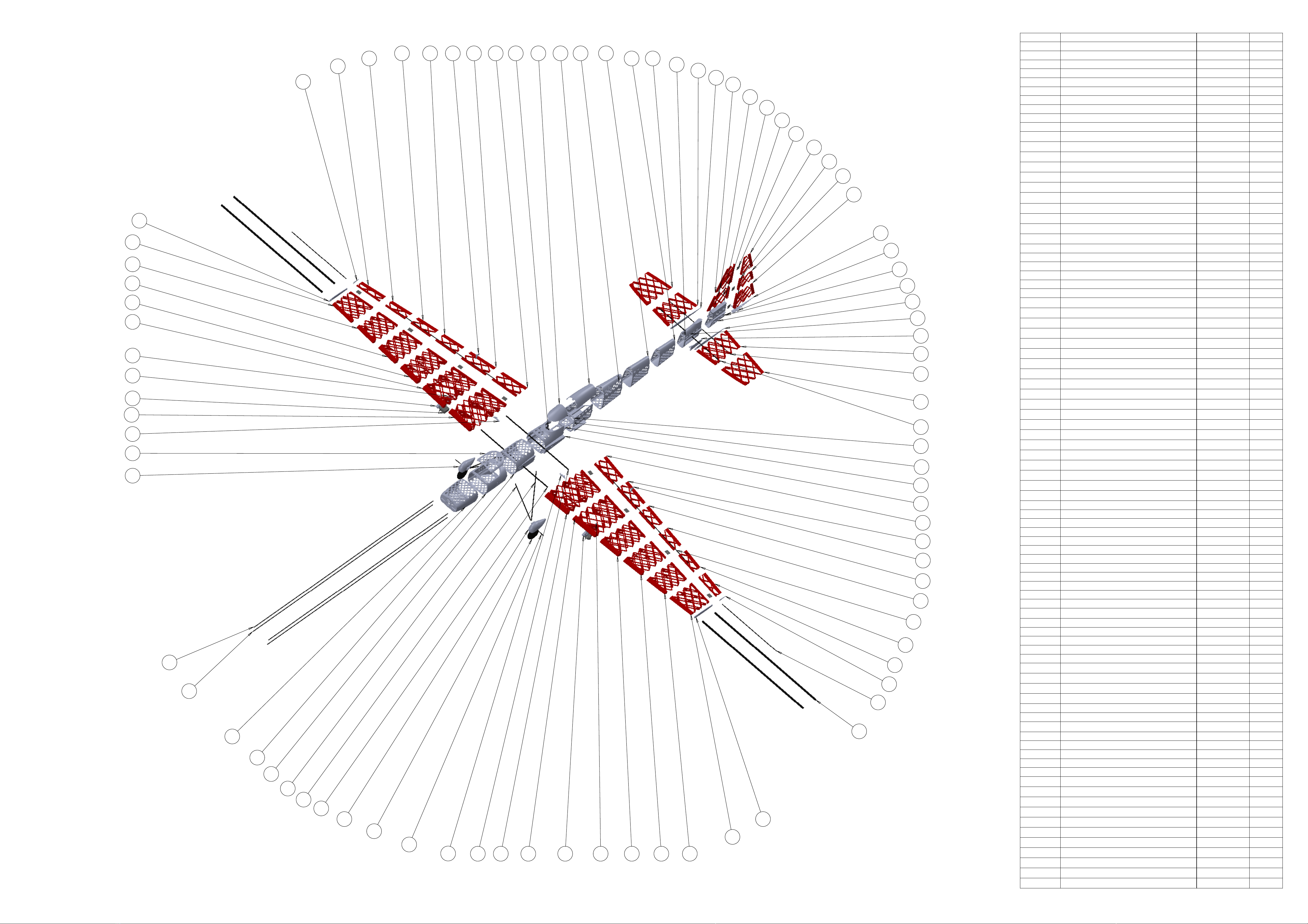

Parts choices

For some parts there are more options and it is up to you what you will choose depending on your

preferences. All options can be found in Options directory.

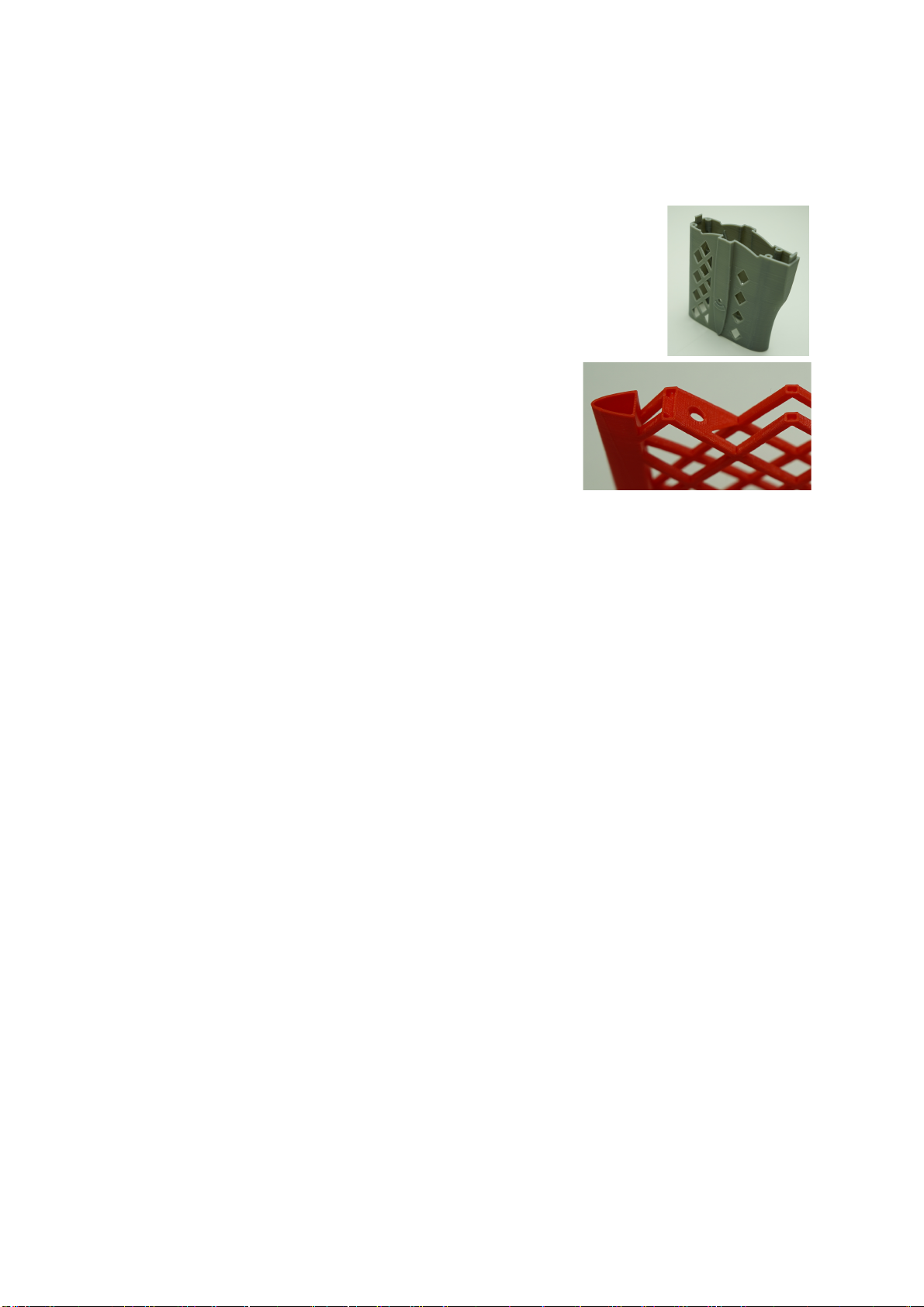

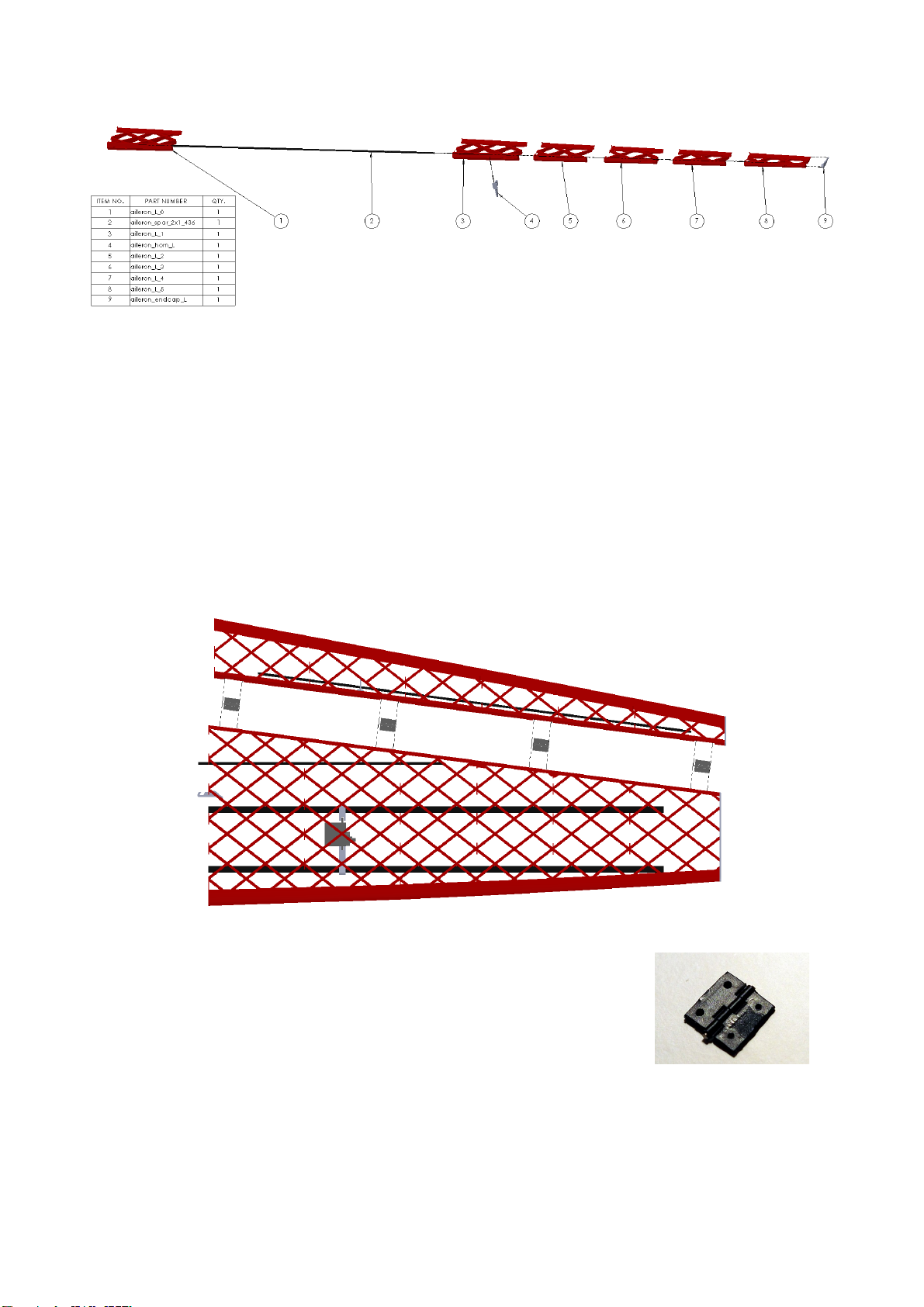

Choices based on hinge. You can use two kinds of hinges, both have same length and width

(roughly 28mm x 16 mm) but thickness is where they differ. European style is 1.2mm thick and Du-

Bro 117 is roughly 0.3 inch thick:

•parts in main directory have slots for European hinge

•parts under Options directory ending with suffix _dubro.STL have slots for Du-Bro 117

standard hinges

Choices based on wheel size:

•shoe_L.STL and shoe_R.STL will accommodate 45mm wheel

•shoe_L_50mm.STL and shoe_R_50mm.STL from Options directory will accommodate

50mm wheel

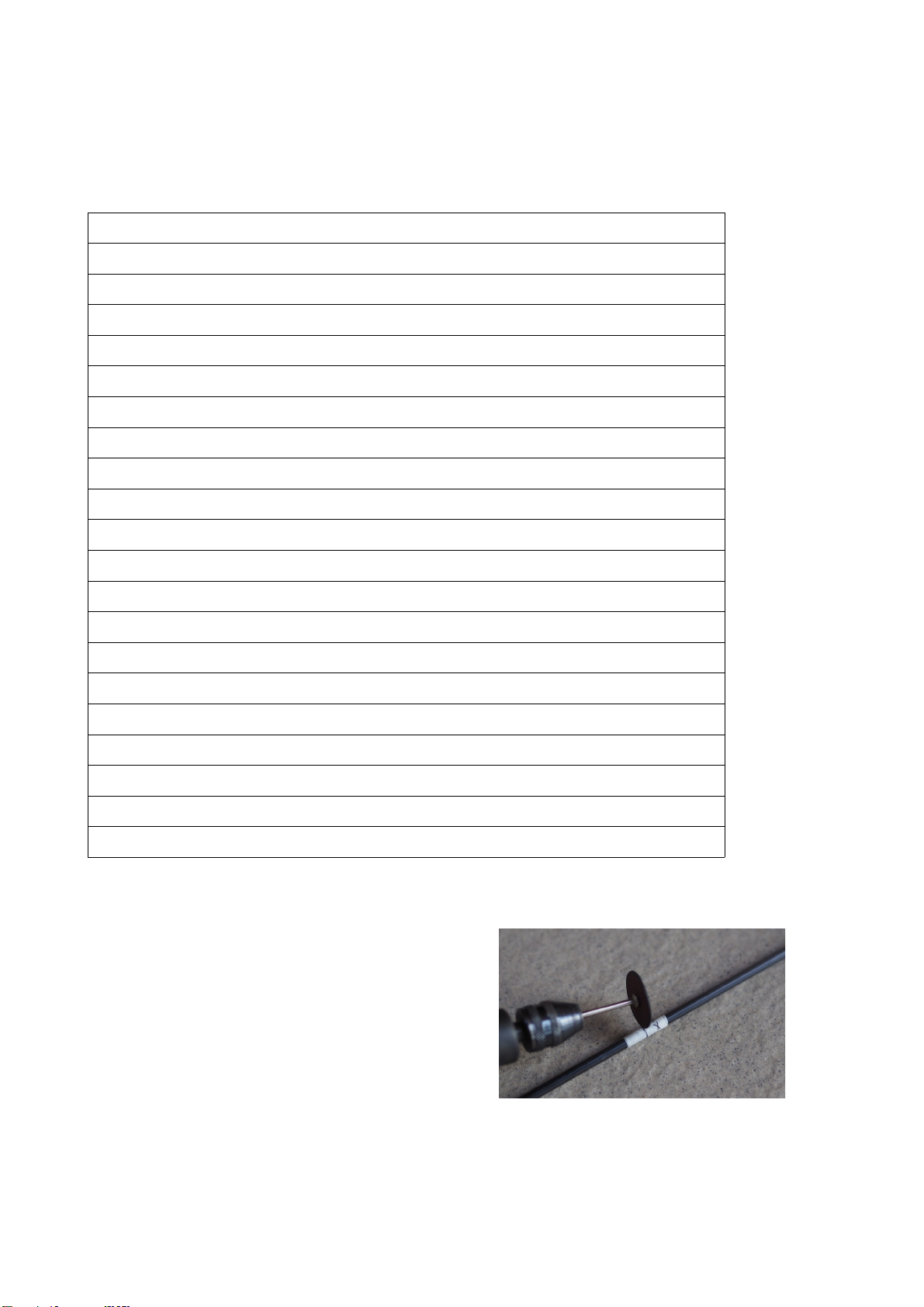

Choices for motor mount. In first version of Maripi files part fuse_0_SK3_35xx.STL had some

design issues that caused firewall breaking and complete motor separation from the fuselage after

rough landing or after longer use due to the motor vibrations. In version 1.1 this part was improved.

Namely carbon spars are protruding more into firewall and some small fillets were added. This fix

was still not good enough. That is why I improved it much more in this version. I added more fillets

on all critical places. Air inlets are much smaller and moved away from motor mount holes to

prevent cracks around motor screws. Also motor mount screw holes have now smaller countersink.

Despite all my changes some of you felt that it is still now enough and that is why added heavy duty

version of fuse_0 with thicker firewall and no countersinks for motor screws:

•fuse_0_SK3_35xx.STL in main directory is strong enough to withstand serious abuse

•fuse_0_SK3_35xx_heavy_duty.STL is even stronger but requires you to use your own

longer screws with flat bottom.

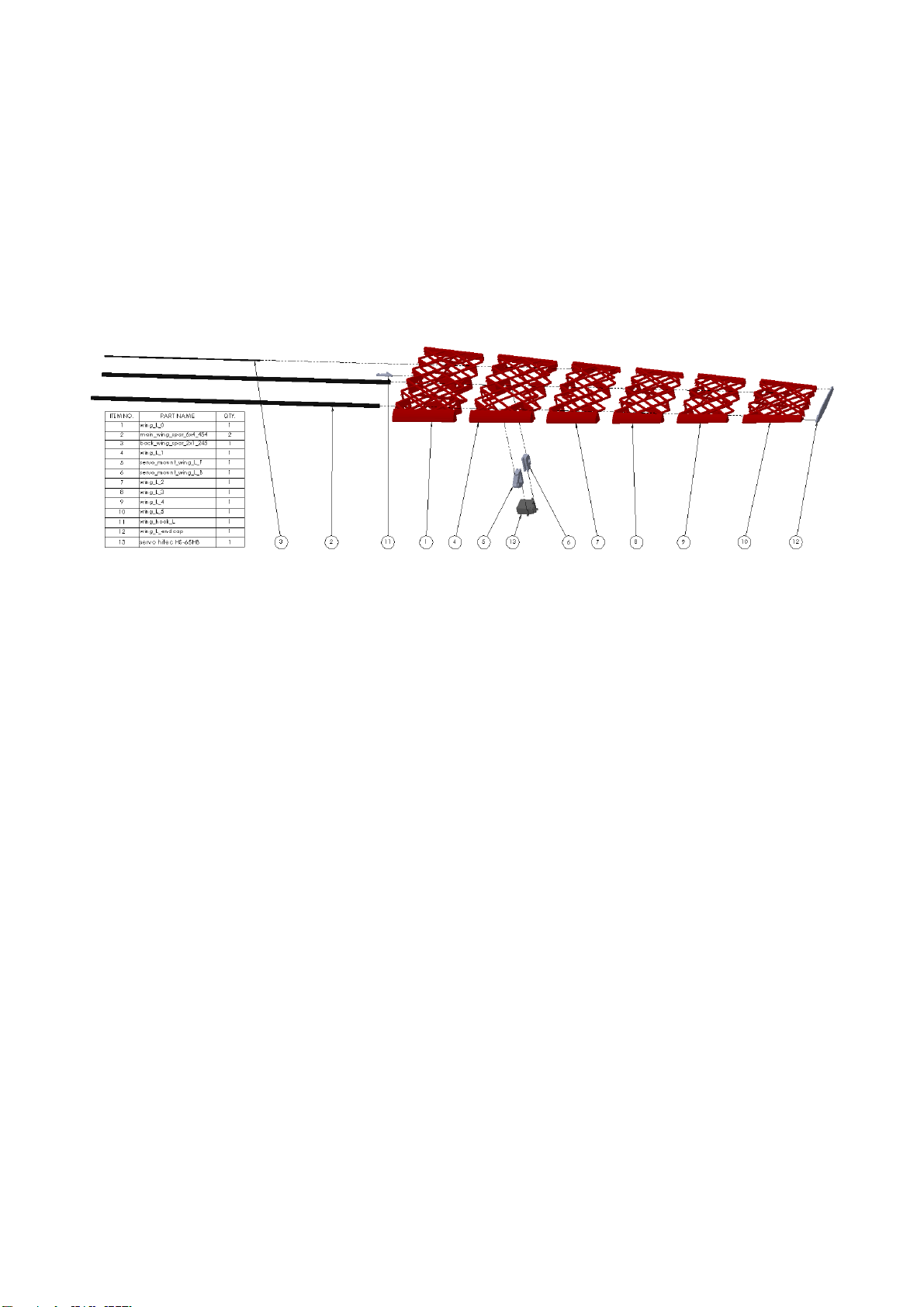

Choices based on servo in the wing:

•servo_mount_wing_[position]: will fit Hitec HS-65 (mg or hb) servo

A = 2 mm, B = 24 mm, C = 32.5 mm, D = 11.6 mm, E = 17 mm

•servo_mount_wing_generic_[position]: there are included both STL

and STEP file, you can customize it in software or manually after the

mount is printed out

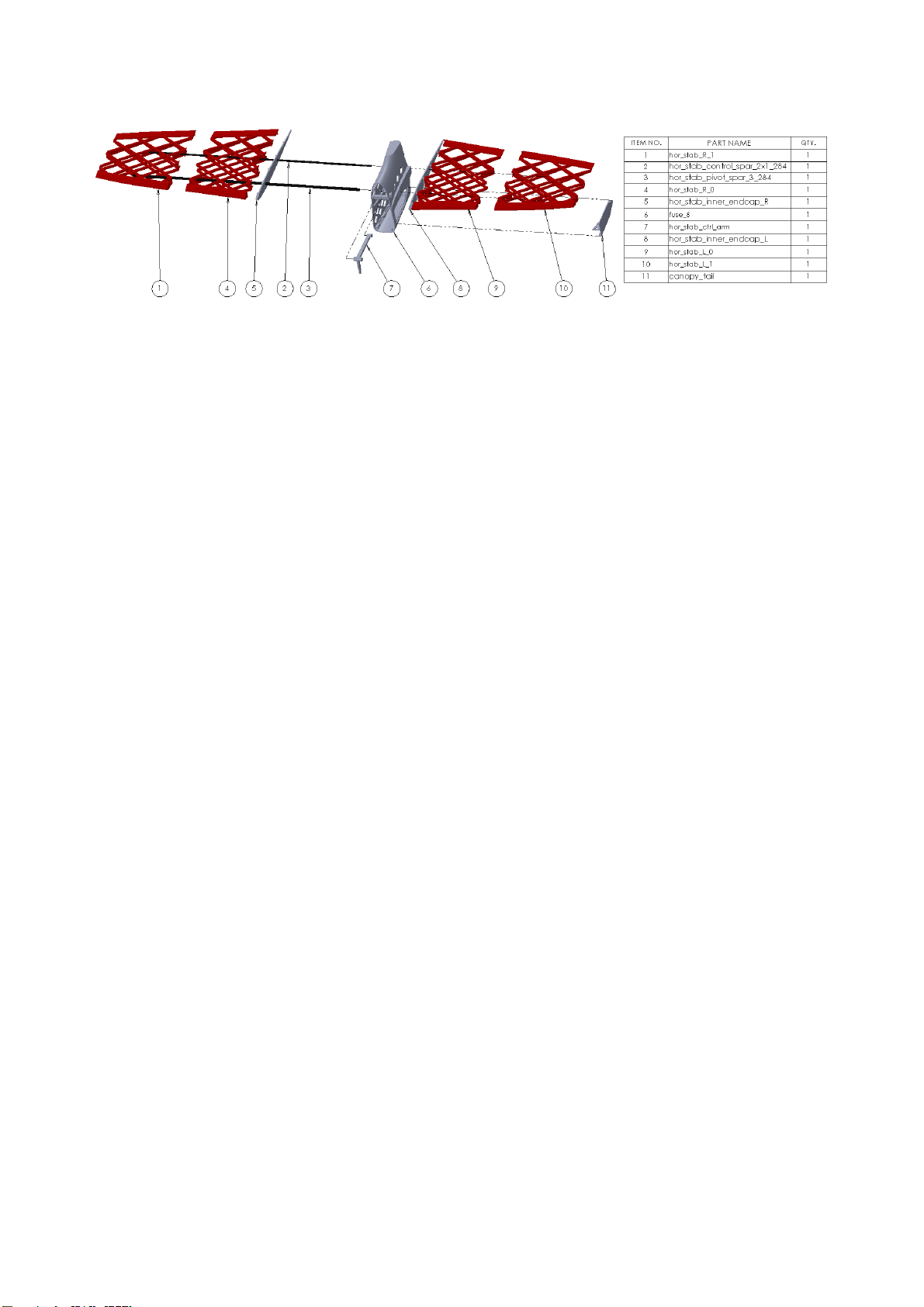

Choices based on servo in the fuselage:

•servo_plate_hs_65: will fit Hitec HS-65 (mg or hb) servo A = 2 mm, B = 24 mm, C = 32.5

mm, D = 11.6 mm, E = 17 mm

•servo_plate_generic: there are included both STL and STEP file, you can customize it in

software or manually after the plate is printed out

support@kragamodels.com