Page 4 For technical questions, please call 1-800-444-3353. Item 69584

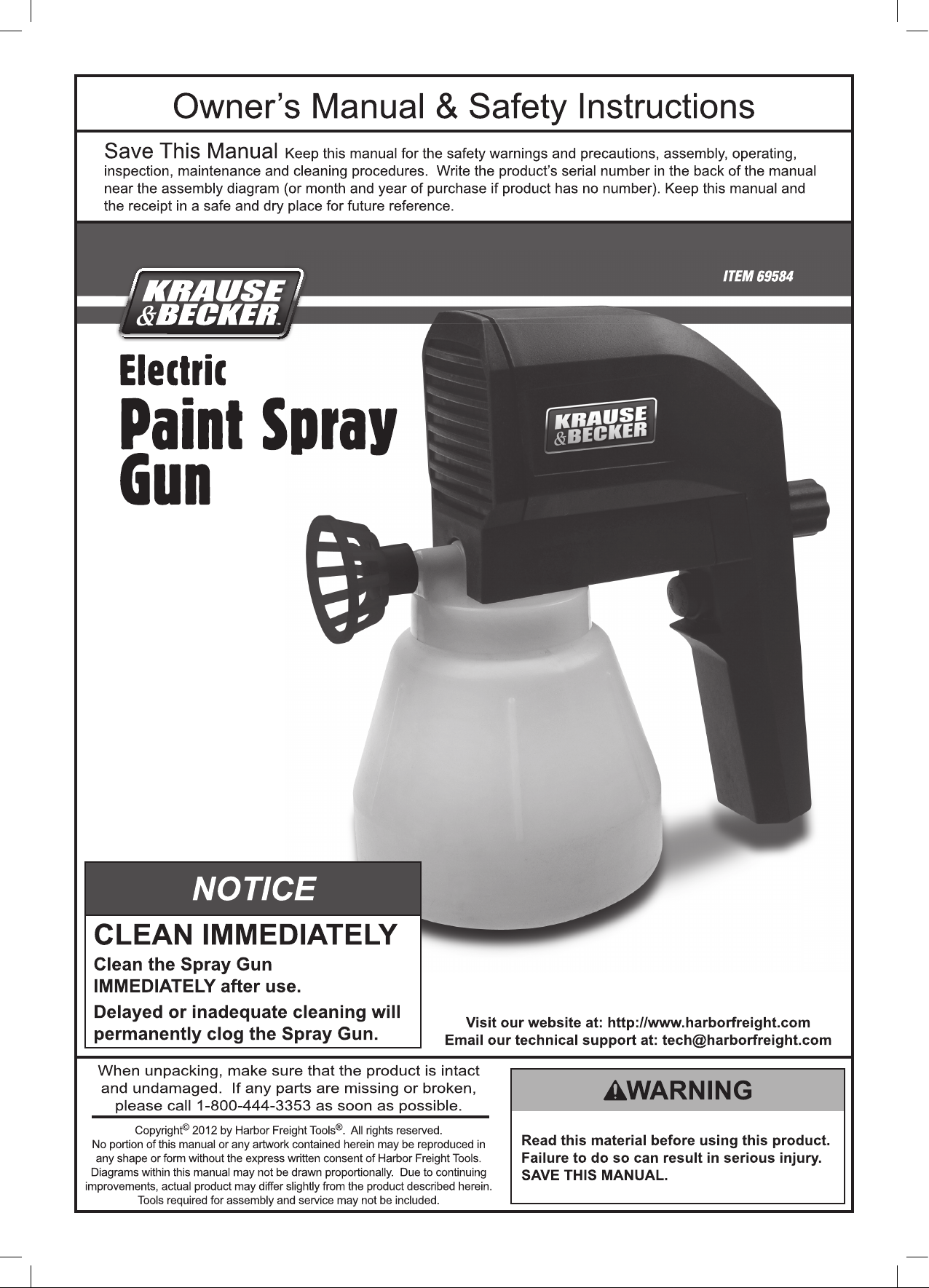

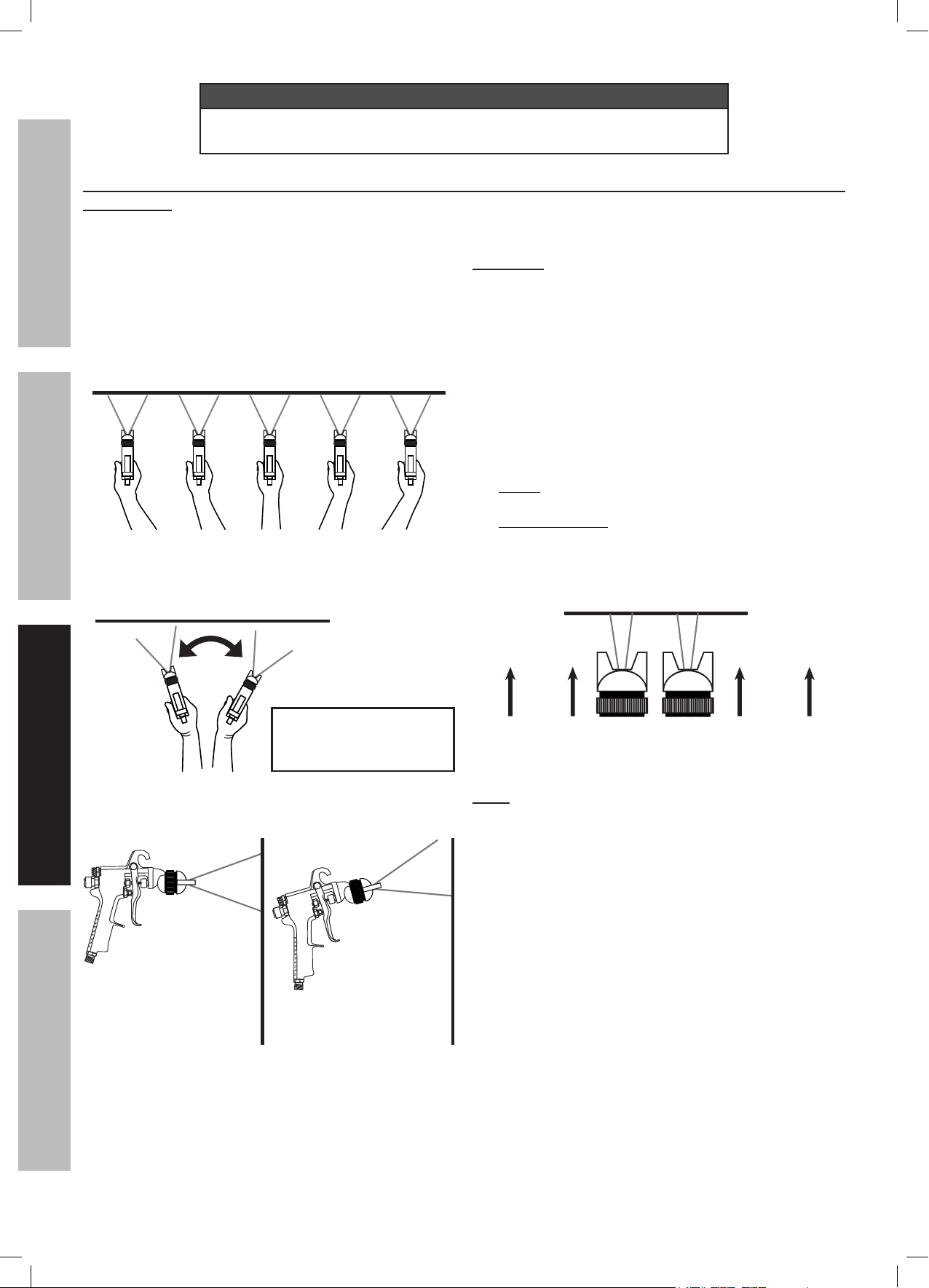

NOTICE

Clean the Spray Gun IMMEDIATELY after use.

Delayed or inadequate cleaning will permanently clog the Spray Gun.

5. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

6. Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified repair person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

Paint Sprayer Safety Warnings

1. Do not direct spray at people or animals.

2. Do not spray near open flames, pilot lights, stoves,

heaters, air compressors, or any other heat source.

Most solvents and coatings are highly flammable,

particularly when sprayed.

3. Read all of the information concerning

coating products and cleaning solvents.

Do not use chlorinated solvents

(e.g. 1-1-1 trichloroethylene and

dichloromethane, also know n as

methylene chloride) to clean spray guns.

Many spray guns contain aluminum,

which reacts strongly to chlorinated solvents.

Contact the solvent or coating manufacturer as

needed regarding potential chemical reactions.

4. Industrial applications must follow

OSHA requirements.

5. Spraying hazardous materials may result in serious

injury or death. Do not spray pesticide, acid,

corrosive material, fertilizer, or toxic chemicals.

6. Paints and solvents may be harmful or fatal

if swallowed or inhaled. Avoid prolonged skin contact

with solvents or paints as they will irritate skin.

After any contact, immediately wash off

exposed area with hot, soapy water.

7. Maintain labels and nameplates on the tool.

These carry important safety information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

8. Avoid unintentional starting.

Prepare to begin work before turning on the tool.

9. Do not leave the tool unattended when it is plugged

into an electrical outlet. Turn off the tool, and

unplug it from its electrical outlet before leaving.

10. This product is not a toy.

Keep it out of reach of children.

11. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields in

close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

In addition, people with pacemakers should:

• Avoid operating alone.

• Do not use with power switch/trigger locked on.

• Properly maintain and inspect to avoid

electrical shock.

• Properly ground power cord. Ground Fault Circuit

Interrupter (GFCI) should also be implemented

– it prevents sustained electrical shock.

12. WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities, contains chemicals known [to the

State of California] to cause cancer, birth defects

or other reproductive harm. An example of

these chemicals are: • Lead from lead-based paints

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to

filter out microscopic particles.

(California Health & Safety Code § 25249.5, et seq.)

13. WARNING: Handling the cord on this product will

expose you to lead, a chemical known to the State of

California to cause cancer, and birth defects or other

reproductive harm. Wash hands after handling.

(California Health & Safety Code § 25249.5, et seq.)

14. The warnings, precautions, and instructions

discussed in this instruction manual cannot cover all

possible conditions and situations that may occur.

It must be understood by the operator that

common sense and caution are factors

which cannot be built into this product, but

must be supplied by the operator.

SAVE THESE INSTRUCTIONS.

SAFETY OPERATION MAINTENANCESETUP