DEVICE DESCRIPTION

2

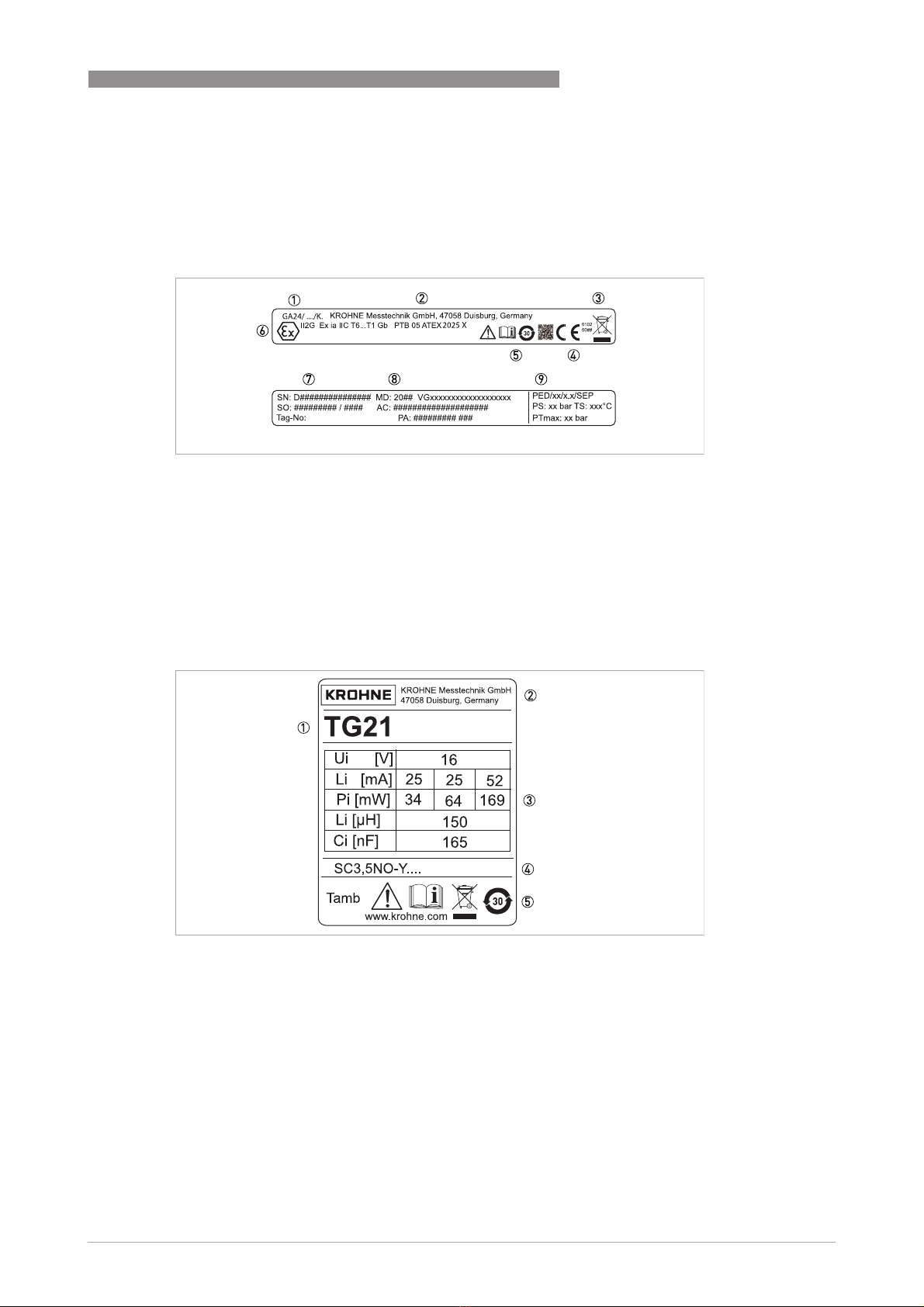

9

GA24

www.krohne.com10/2020 - 4000836703 - AD GA24 Exia Gb R04 en

2.7 Ambient temperature / temperature classes

Due to the influence of the product temperature, no fixed temperature class is assigned to

variable area flowmeters. The temperature class of these devices is rather a function of the

present product temperature and ambient temperature. There is no distinction between devices

with one or two contacts. The classification is outlined in the following tables.

The tables take into account the following parameters:

•Maximum values P

i

•Ambient temperature T

amb.

•Product temperature T

m

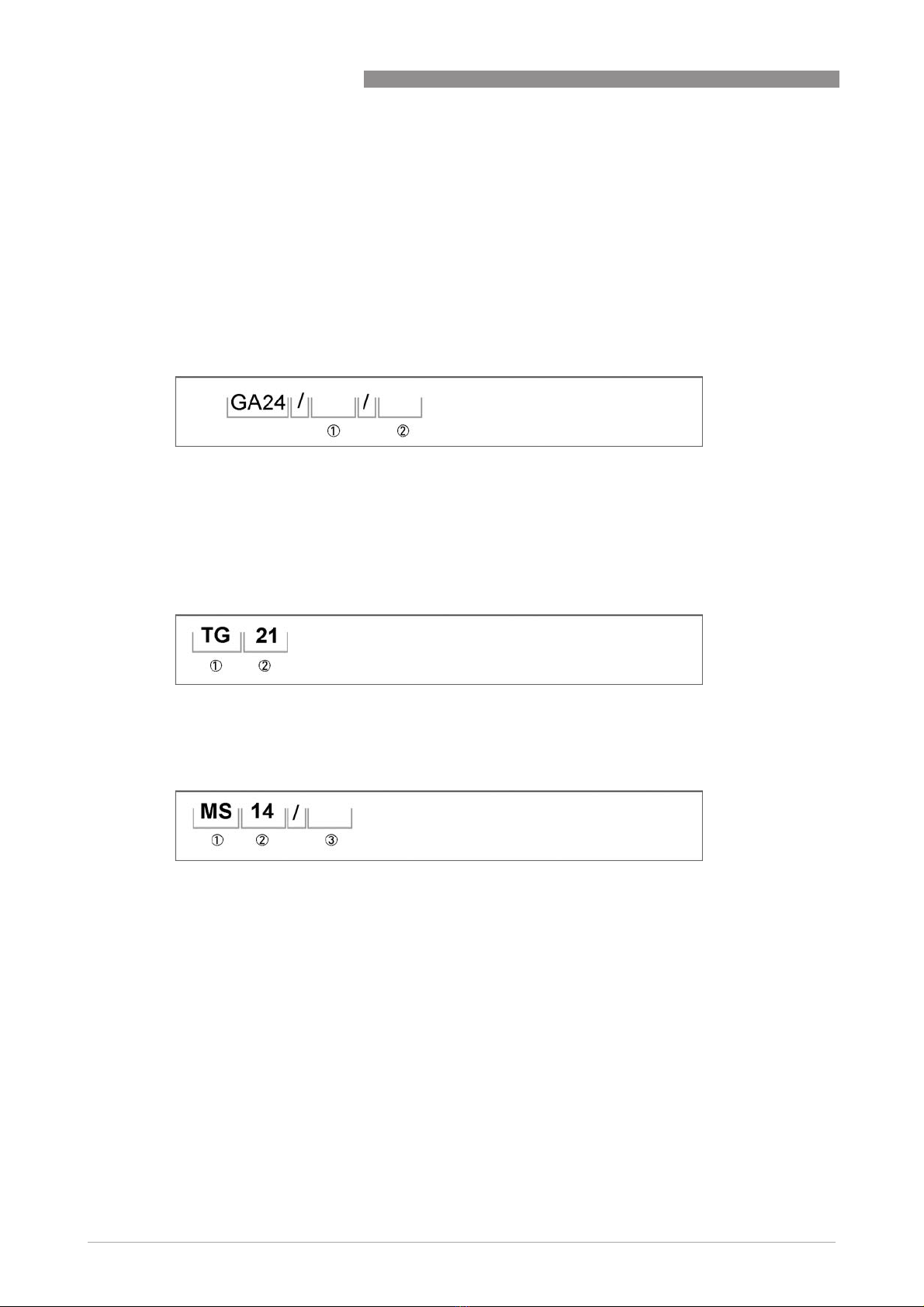

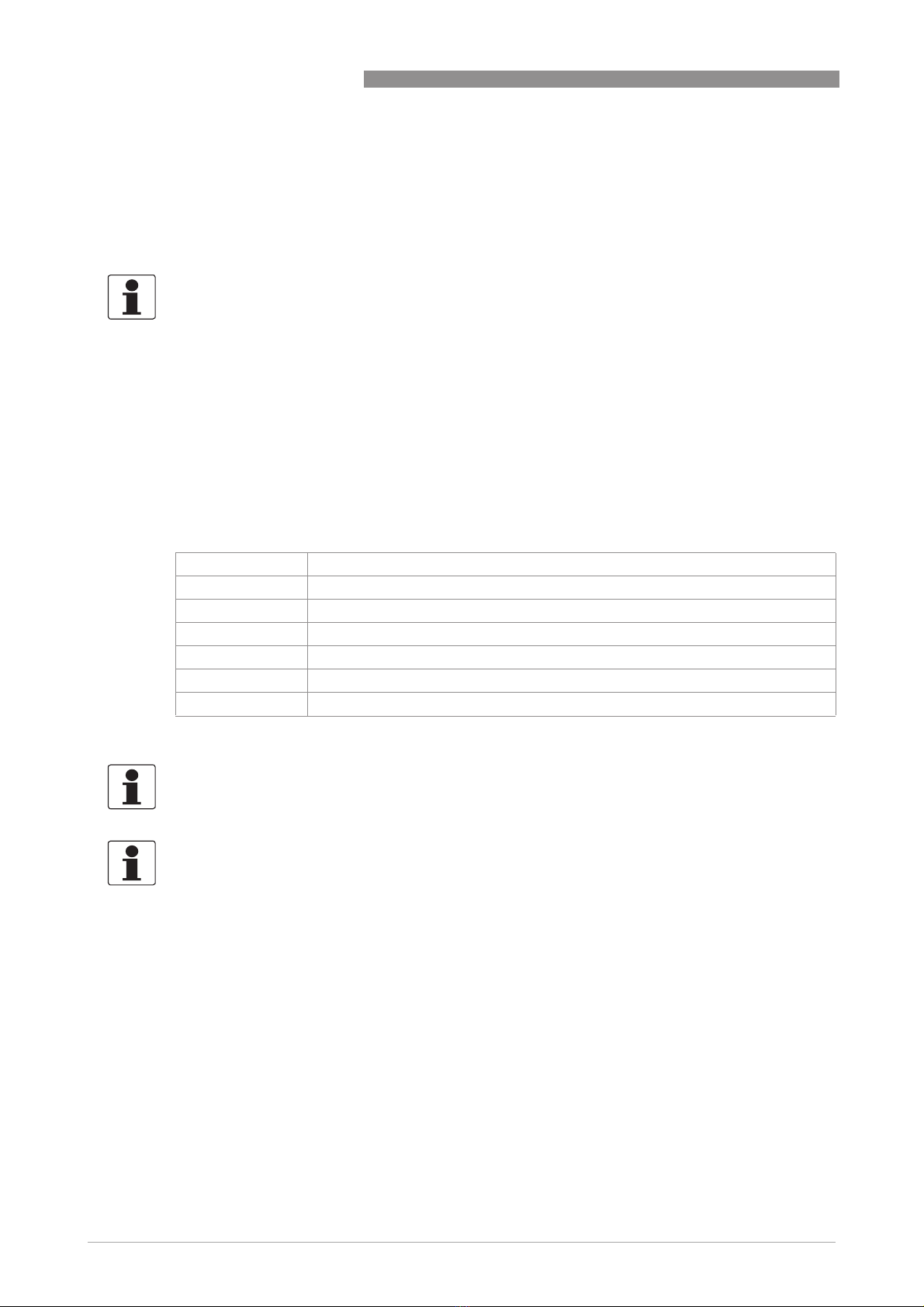

•Limit switch TG21 or MS14

Maximum permissible product and ambient temperatures for TG21

Maximum permissible product and ambient temperatures for MS14/.

The maximum product and ambient temperature is +85°C / +185°F.

These values may be limited by the information contained in the standard manual.

The maximum values listed in the manual must be taken into consideration.

Minimum product temperature for all versions

The minimum product temperature is -20°C/-4°F.

INFORMATION!

The maximum permissible product temperatures listed in the tables are valid under

the following conditions:

•

The measuring device is installed and operated in accordance with the installation

instructions in the standard manual.

•

It must be ensured that the flowmeter is not heated by the effects of additional heat radiation

(sunshine, neighboring system components) and thus operated above the permissible

ambient temperature range.

•

Insulation must be limited to the piping.

Unobstructed ventilation of the indicator part must be ensured.

Supply Type 1 [ ≤34mW] Type 2 [ ≤64mW] Type 3 [ ≤169mW]

Temperature class T6 T5 T4...T1 T6 T5 T4...T1 T6 T5 T4...T1

Max. product temperature

[°C] 70 85 95 60 75 95 35 50 70

Max. product temperature

[°F] 158 185 203 140 167 203 95 122 158

Table 2-2: Max. permissible product and ambient temperatures TG21