GB-4

Contact

If you have any technical questions, please contact

your local branch office/agent. The addresses are

available on the Internet or from ElsterGmbH.

We reserve the right to make technical modifications

in the interests of progress.

Elster GmbH

Strotheweg 1, D-49504 Lotte (Büren)

Tel. +49 541 1214-0

Fax +49 541 1214-370

Contact

Designed lifetime

This information on the designed lifetime is based on

using the product in accordance with these operating

instructions. Once the designed lifetime has been

reached, safety-relevant products must be replaced.

Designed lifetime (based on date of manufacture)

in accordance with EN 13611 for GFK: 10 years.

You can find further explanations in the applicable

rules and regulations and on the afecor website

(www.afecor.org).

This procedure applies to heating systems. For

thermoprocessing equipment, observe local regu-

lations.

Logistics

Transport

Protect the unit from external forces (blows, shocks,

vibration). On receipt of the product, check that the

delivery is complete, see page 2 (Part designa-

tions). Report any transport damage immediately.

Storage

Store the product in a dry and clean place.

Storage temperature: see page3 (Technical data).

Storage time: 6months before using for the first

time. If stored for longer than this, the overall service

life will be reduced by the corresponding amount of

extra storage time.

Packaging

The packaging material is to be disposed of in ac-

cordance with local regulations.

Disposal

Components are to be disposed of separately in

accordance with local regulations.

Certification

Declaration of conformity

We, the manufacturer, hereby declare that the prod-

uct GFK, marked with product ID No.0063AU1408,

complies with the essential requirements of the fol-

lowing Directives and Standards:

Directives:

– 2009/142/EC – GAD (valid until 20 April 2018)

– 2014/68/EU

Regulation:

– (EU) 2016/426 – GAR (valid from 21 April 2018)

The relevant product corresponds to the tested type

sample.

The production is subject to the surveillance proce-

dure pursuant to Directive 2009/142/EC AnnexII

paragraph 3 (valid until 20 April 2018) and to Regula-

tion (EU) 2016/426 Annex III paragraph 3 (valid from

21 April 2018).

Elster GmbH

Scan of the Declaration of conformity (D,GB)– see

www.docuthek.com

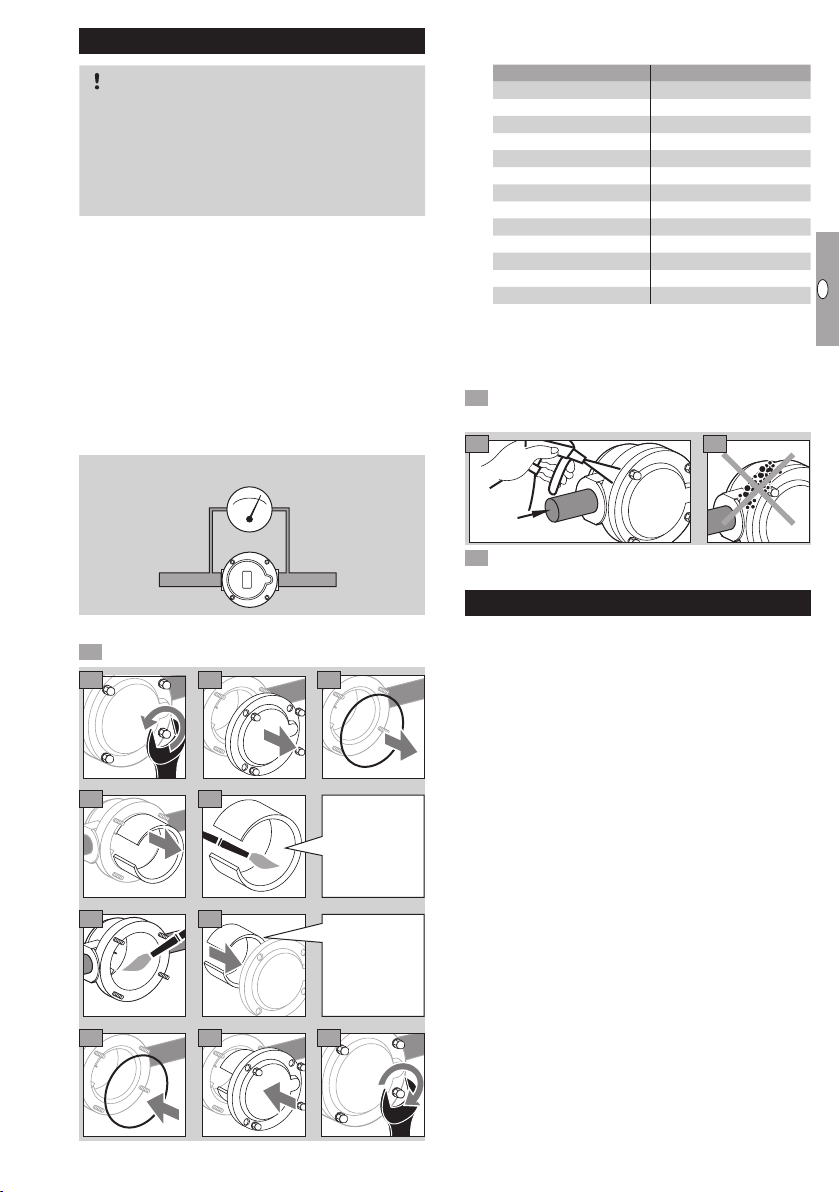

Filter pads

With 50µm separation rate

Designation Order No.

Spare parts set GFK 15/20,

10 filter pads and 10 O-rings 71935010

Spare parts set GFK 25/32,

10 filter pads and 10 O-rings 71937010

Spare parts set GFK 40/50,

5 filter pads and 5 O-rings 71939010

Spare parts set GFK 65,

1 filter pad and 1 O-ring 74923284

Spare parts set GFK 80,

1 filter pad and 1 O-ring 74923285

Spare parts set GFK 100,

1 filter pad and 1 O-ring 74923286

Filter pad GFK 125 35448581

O-ring 308x8 for GFK 125/150 03110013

Filter pad GFK 150 35448583

O-ring 308x8 for GFK 125/150 03110013

Filter pad GFK 200/250 35448584

O-ring 430x8 for GFK 200/250 03109164

▷

Filter pads with special separation rate of 10µm

for GFK15–100 on request.