This manual is to assist the engineer to avoid the most common fan problems caused by improper storage,

installation, operation and maintenance. HANDLING AND MAINTENANCE SHOULD ALWAYS BE

PERFORMED BY EXPERIENCED AND TRAINED PERSONNEL.

RECEIVING, HANDLING AND STORAGE

Rough handling during shipment and improper storage can cause damage that is not noticeable until the fan is

in operation. This can be avoided with proper storage and handling techniques.

Touch up the scratch coated surfaces during lifting, to prevent corrosion to occur at this area. Store the fan in

a clean and dry place, preferably indoor to ensure fan shaft, bearing and fan casing are protected against dust

and corrosion. Do not store the fan in a location where it will be subjected to high vibration.

This can cause the internal surface to rub against each other and damage the bearings.

START-UP CHECK LIST

Before putting any fan into initial operation the manufacturer’s instruction must be followed. Complete the

following checklist to make sure that the fan is ready to run.

Lock out the primary and all secondary power sources.

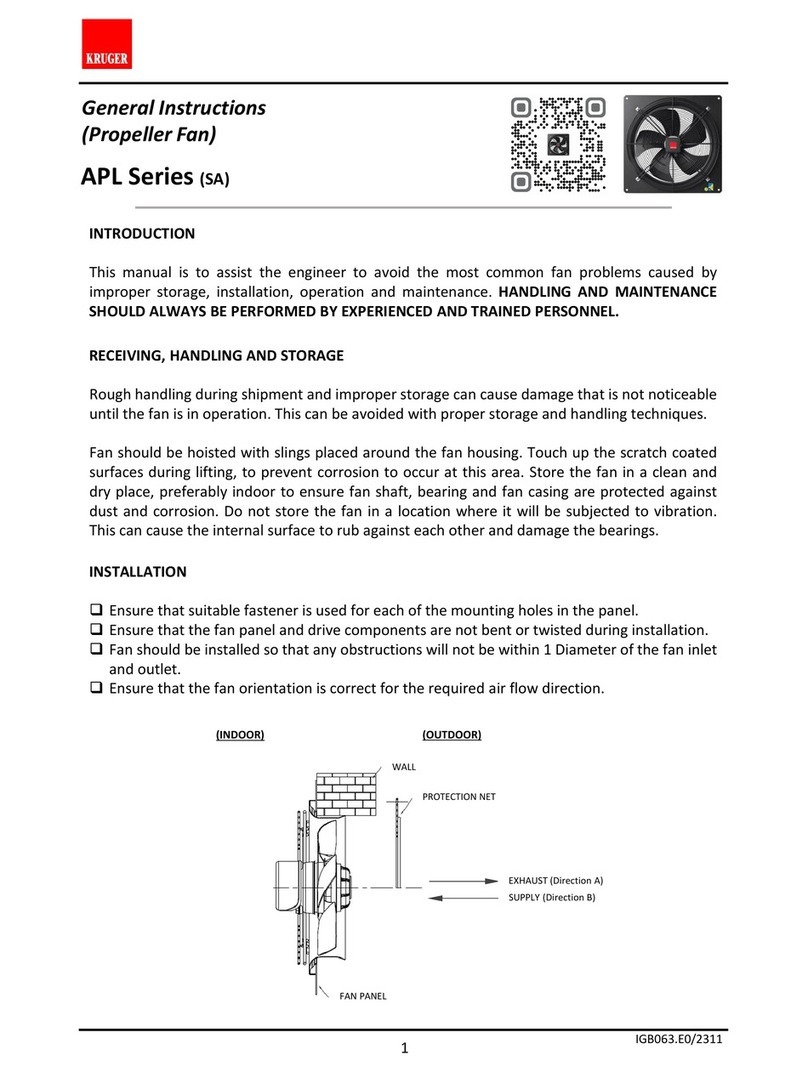

Make sure the foundation or mounting arrangement and the duct

connections are adequately designed in accordance with recognized

acceptable engineering practices.

Check and tighten all hold-down (securing) bolts.

Spin impeller to see whether it rotates freely and is not grossly out of balance.

Inspect impeller for correct rotation for the fan design.

Check belt drive alignment, use recommended belt tension.

Check belt drive for proper sheave selection and make sure they are not

reversed.

Properly secure all safety guards.

Switch on the electrical supply and allow the fan to reach full speed.

Check carefully for :- (1) Excessive vibration

(2) Unusual noise

(3) Proper amperage and voltage values

(4) Proper belt alignment

If any problem is indicated, SWITCH OFF IMMEDIATELY. Lock out the

electrical supply, secure the fan impeller if there is a potential for wind

milling. (impeller turning due to a draft through the system).

Check carefully the cause and correct as required.

The fan may now be put into operation but during the first 8 hrs of running, it should be periodically observed

and checked for excessive vibration and noise. Check the motor input current and motor temperature to

ensure that they do not exceed manufacturer’s recommendation. After 8 hrs of operation, the fan should be

shut down to check for the following items:

(1) All set screws and hold-down bolts

(2) Belt drive alignment

(3) Belt drive tension

(4) Bearing housing temperature

* For V-belt drive installation and belt tension, please refer to our general installation guide for

Centrifugal Fan (IGB016.0/0600) for more information.