MAINTENANCE

Before carry out cleaning or maintenance, disconnect the main electrical supply to

the fan by means of a double pole switch or remove the plug.

Remove the grille.

Clean the grille using lukewarm water neutral detergent and rinse with clean

water.

Wipe the main body with cloth and neutral detergent.

Fit the grille back when it is dry.

Note :

When power cord is replaced, the cord diameter should not be less than 0.5mm2

and it must be double covered and must use the fixing terminal and special tools

to work.

Do not put fingers into To prevent electric shocks, do not

the grille spray water near the ventilation fan

BREAKDOWN REPAIR

Fan blades not running

when the power is on

2. If the fan blades are

blocked

2. Remove and clean

the grille

Specification and sizes of parts

Accessories: screw: (#4x25)~ 5pcs & (#4X14)~2pcs

* dB (A) –Sound pressure level at 3 meter.

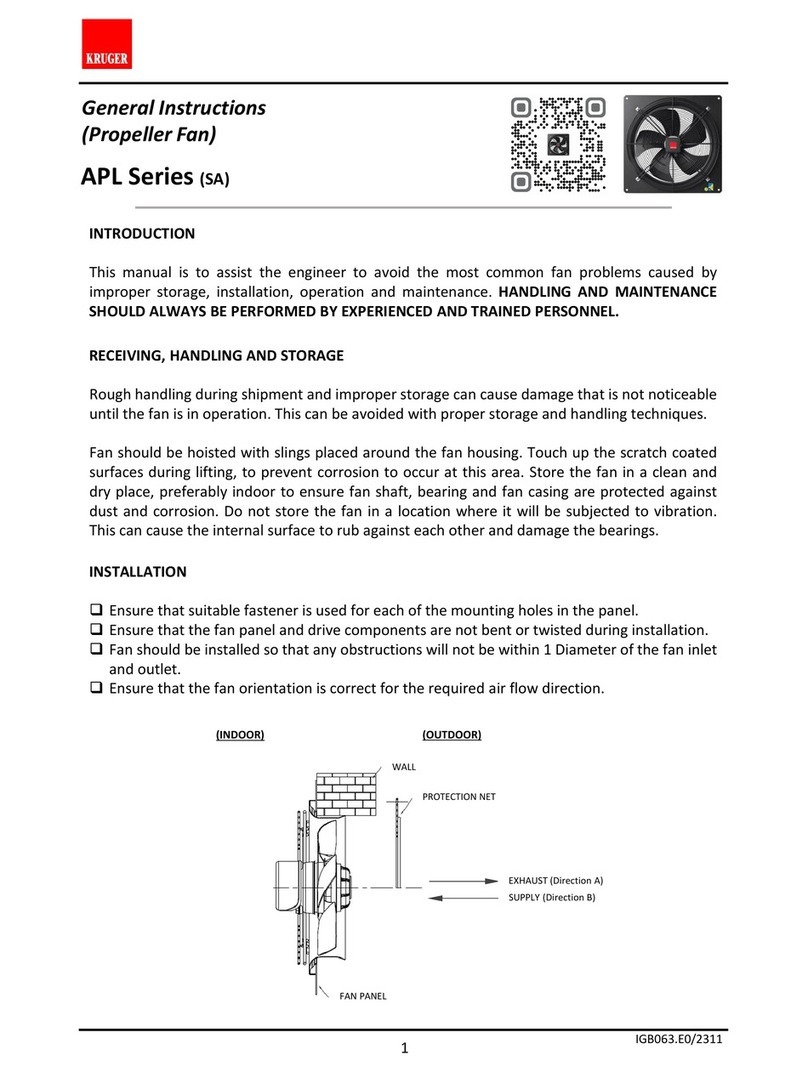

General Instructions

KCE 300 L

IGB013.E1/0703

48.5

370

129.5

234.5

KRUGER GROUP

SINGAPORE

Kruger Ventilation Industries Pte Ltd

No. 17, Tuas Avenue 10

Singapore 639141

Tel. +65 68611577 –Fax +65 68613577

MALAYSIA

Kruvent Industries (M) Sdn Bhd

Lot 8, Jalan Perusahaan 2 Batu Caves

Industrial Area, 68100 Batu Caves Selangor

Tel. +603 61888293 –Fax +603 61898843

BEIJING

Bejing Kruger Ventilation Co. Ltd

No. 1A South Industry Area

Beijing Economical And Technological

Development Area, Beijing China 100176

Tel. +86 10-67881366 –Fax +86 10-67880566

HONG KONG

Kruger Ventilation (Hong Kong) Limited

Flat C, 9/F,

Yeung Yiu Chung (No. 8) Industrial Building,

20 Wang Hoi Road,

Kowloon Bay, Kowloon, Hong Kong

Tel. +852 22469182 –Fax +852 22469187

WUHAN

Wuhan Kruger Ventilation Co. Ltd

Xincheng Road 10, South Dongwu Ave,

Dongxihu District, Wuhan, Hubei, P.R.China 430040

Tel. +86 27-83248840 –Fax +86 27-83261886

PHILIPPINES

Kruger M&E Industries Corporation

FAPI Compound, E. Rodriguez Ave.

Tunasan, Muntinlupa City, Philippines 1773

Tel. +63 2-8622891-97 –Fax +63 2-8621287

INDONESIA

P.T. Kruger Ventilation Indonesia

JL. Teuku Umar No.20

Karawaci –Tangerang 15115, Indonesia

Tel. +62 21-5512288/5513557 –Fax +62 21-5513502

KOREA

Neomate Technology & Consulting Co. Ltd

2-1010, Ace High City B/D, Mullae-dong 3-ga

Yeongdeungpo-gu, Seoul, Korea, 150-972

Tel. +82 2-26792052 –Fax +82 2-26792174

DUBAI

Kruger Ventilation Industries, Gulf Branch

Jebel Ali Free Zone Area (JAFZA)

Near Roundabout 8, Warehouse No. RA08FC05

P.O. Box No. 262949

Tel. +971 4-8832017 –Fax +971 4-8832018

SINGAPORE

Kruger Engineering Pte Ltd

No. 17, Tuas Avenue 10

Singapore 639141

Tel. +65 68631191 –Fax +65 68631151

THAILAND

Kruger Ventilation Ind. (Thailand) Co. Ltd

30/105 Moo 1 Sinsakorn Industrial Estate

Chetsadawithi Road, Khok Kham Mueng,

Sakuthsakorn 74000, Thailand

GUANGZHOU

Guangzhou Kruger Ventilation Co. Ltd

No. 9 Huahui Road, Huashan

Huadu, Guangzhou, P.R. China

Tel. +86 20-86786070 –Fax +86 20-86786001/86786500

SHANGHAI

Shanghai Kruger Ventilation Co. Ltd

No. 500 Yuanguo Road, Anting, Jiading,

Shanghai 201814, P.R. China

Tel. +86 21-69573266 –Fax +86 21-69573296

TAIPEI

Kruger Ventilation (Taiwan) Co. Ltd

No. 157, Ping-an Rd, Hengfeng Village,

Dayuan Shiang Taoyuan County 337, Taiwan (ROC)

Tel. +886 3-3859119 –Fax +886 3-3859118

AUSTRALIA

S&P-Kruger Australia Pty Ltd

2 Cunningham St

Moorebank N.S.W. 2170

Tel. +61 2-98227747 –Fax +61 2-98227757

INDIA

Kruger Ventilation Industries (India) Pvt Ltd

Kruger Centre, Mumbai-Nasik Highway,

Atgaon, Shahapur, Thane 421304, Maharashtra, India

Tel. +91 9860730999 –Fax +91 2527240075

VIETNAM

Kruger Ventilation Industries Pte Ltd

(Vietnam Representative Office)

4th Floor, HHM Office Building, 157-159 Xuan Hong St,

Tan Binh Dist, Hochiminh City, Vietnam

Tel. +84 8-6-2968123 –Fax +84 8-6-2968124

Ø144

Tel. +662 1050399 –Fax +662 1050370-2