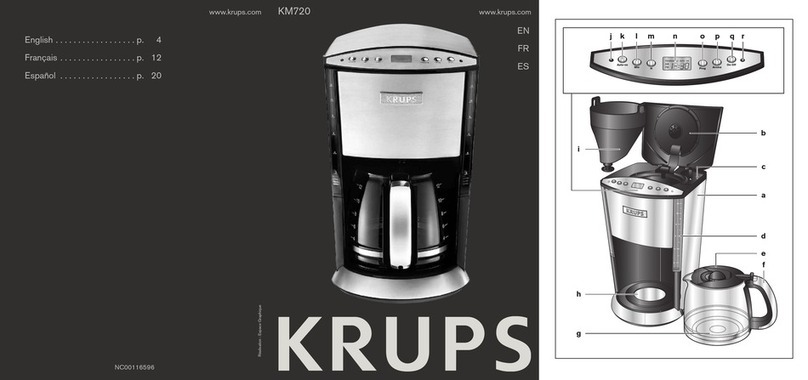

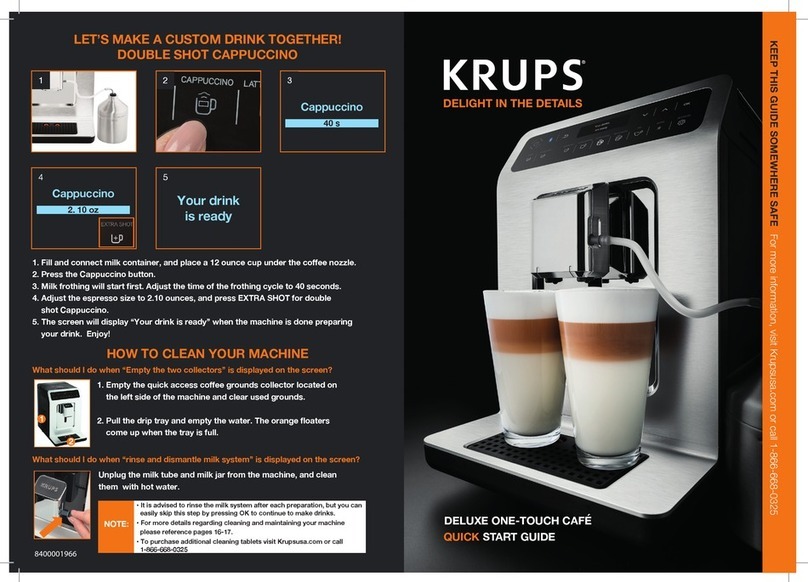

Pictographic model

oConsult the grinding time programmed in the coffee-maker:

see grinder setting 0, 2, 4, 6 or 8 in the small display in line 22 of the 1st-level After-

Sales (A-S) mode.

GRINDER 1 (applied until 13/02/2006)

oAccess to V16 setting mode (self-test procedure at the end of the assembly line)

With cake tray, draw and tank removed

Press "steam" key + mains connection

Æ"cake tray" light comes on + "water" light flashes

oReplace the cake tray, draw and tank

oSet volume selector on minimum position

oPlace a receptacle under the coffee nozzle

oPress standard coffee key Îstart of standard coffee cycle

oBlue On/Off light comes on

oWith the rotating button, select the light corresponding to the one indicated in the table

below.

oPress the "service" key to validate (3 relay pulses)

oDisconnect the coffee-maker.

oAccess to V17 setting mode and future versions (self-test procedure at the end of the

assembly line):

Îsame as for V16 except that setting operation is carried out before the standard

coffee cycle

With cake tray, draw and tank removed

Press "steam" key + mains connection

oÎBlue On/Off light comes on (or another lamp if the selector is not on the minimum

position)

oWith the rotating button, select the desired cake thickness in accordance with the

table below.

oPress the "service" key to validate

oÎ"Cake tray" light comes on + "water" light flashes

oDisconnect the coffee-maker.

Light comes on on the

pictographic model On/Off Cake tray Tank Clean Calc

Grinder position (read-off

in line 22 of A-S mode) 0 2 4 6 8

Time for strong coffee

grinding (secs.) 4.1 4.3 4.5 4.7 4.9

(grinder 1 Î13/02/2006)

GRINDER 2 (applied from the 14/02/2006)

Access to V28 setting mode and future versions (self-test procedure at the end of the

assembly line) :

Îsetting procedure the same as V17, but with data of table below:

Light comes on on the

pictographic model On/Off Cake tray Tank Clean Calc

Grinder position (read-off

in line 22 of A-S mode) 0 10 20 30 40

Time for strong coffee

grinding (secs.) 6 7 8 9 10

(grinder 2, 14/02/2006Î)

6