Contents

Glossary..........................................................................................................................................................................4

1 General ................................................................................................................................................... 5

1.1 Principles..................................................................................................................................... 5

1.2 Target group ................................................................................................................................. 5

1.3 Other applicable documents........................................................................................................... 5

1.4 Symbols ........................................................................................................................................ 5

2 Safety...................................................................................................................................................... 6

2.1 Key to safety symbols/markings ..................................................................................................... 6

2.2 General............................................................................................................................. 6

2.3 Intended use ........................................................................................................................... 7

2.4 Personnel qualification and training .............................................................................................. 7

2.5 Consequences and risks caused by non-compliance with this manual .................................................. 7

2.6 Safety awareness.................................................................................................................... 7

2.7 Safety information for the operator/user .................................................................................... 8

2.8 Safety information for maintenance, inspection and installation ...................................................... 8

2.9 Unauthorised modes of operation.................................................................................................. 8

3 General safety regulations ................................................................................................................... 9

4 Transport/Temporary Storage/Disposal ............................................................................................ 11

4.1 Checking the condition upon delivery .......................................................................................... 11

4.2 Transport.................................................................................................................... 11

4.3 Storage/preservation .................................................................................................................. 12

4.4 Return to supplier.................................................................................................................. 12

4.5 Disposal ........................................................................................................................................... 13

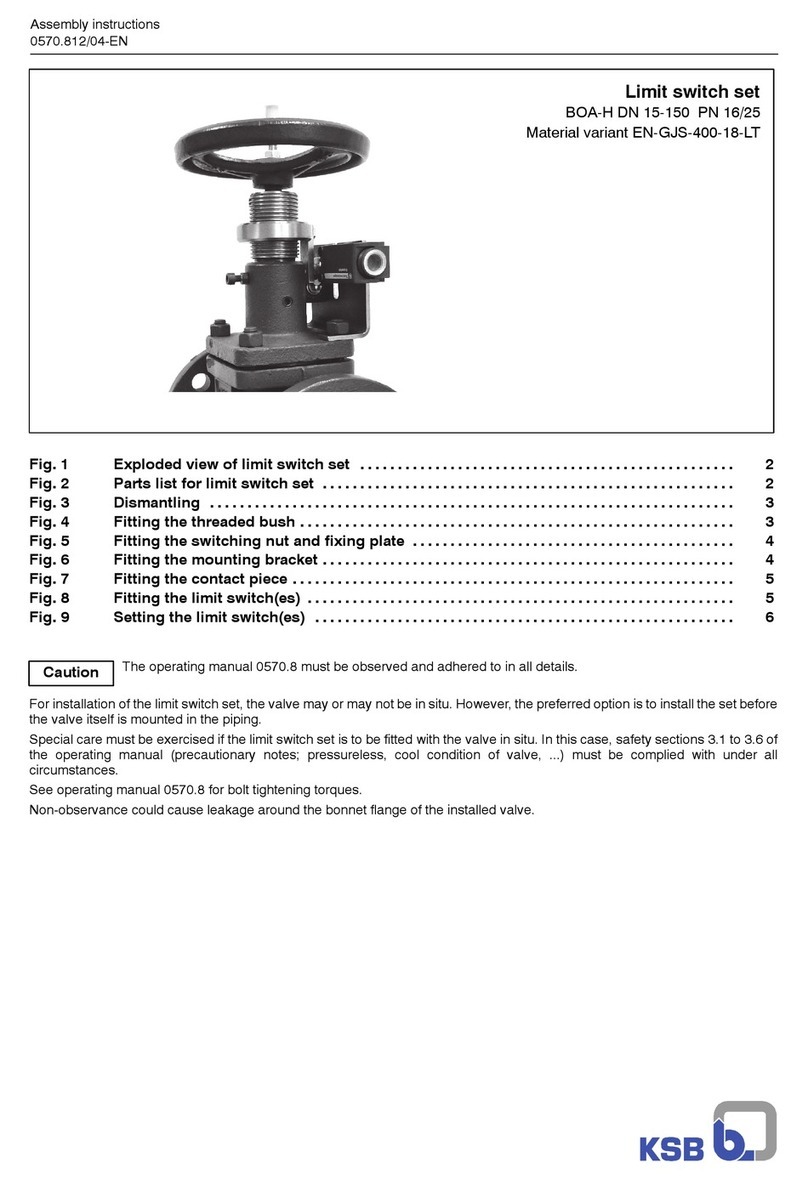

5 Valve Description ...................................................................................................................................... 14

5.1 General description ................................................................................................................... 14

5.2 Marking ............................................................................................................. 14

5.3 Operating data ............................................................................................................................ 16

5.4 Fluids handled ...................................................................................................................... 16

5.5 Design details ............................................................................................................................ 16

5.6 Pressure/temperature ratings................................................................................................. 16

5.7 Materials .............................................................................................................................. 17

5.8 Function .................................................................................................................... 18

5.9 Scope of supply.......................................................................................................................... 18

5.10 Dimensions and weights ........................................................................................................... 18

6 Installation at Site................................................................................................................................ 19

6.1 General information/Safety regulations ....................................................................................... 19

6.2 Installation ..................................................................................................................... 19

6.3 Insulation ……………………………………………………………………………………………………… 20

7 Commissioning/Start-up/Shutdown.............................................................................................................. 21

7.1 Commissioning/Start-up.............................................................................................................. 21

7.1.1 Prerequisites for commissioning/start-up.................................................................................. 21

7.1.2 Actuation ........................................................................................................ 21

7.2 Shutdown............................................................................................................................... 22

7.2.1 Measures to be taken for shutdown .................................................................................. 22

8 Servicing/Maintenance ....................................................................................................................... 23

8.1 Safety regulations ................................................................................................................. 23

8.2 Maintenance ............................................................................................................... 23

8.2.1 (Re-)tightening the bonnet bolting………………………………………………………………….. 24

8.2.2 (Re-)tightening the gland packing………………………………………………………………….. 24

9 Trouble-shooting................................................................................................................................. 25

Index ...............................................................................................................................................................26

Contents

Contents