Safety instructions whose non-observance would involve

hazard to the valve and jeopardize its operation have been

marked with the word

Instructions directly attached to the valve, (e.g. nominal

pressure) must be complied with and maintained in a legible

condition.

3.2 Qualification of personnel and training

The personnel for operation, maintenance,

Inspection and Installation must be adequately

qualified for the work involved. The personnel’s

responsibilities, competence and supervision must be clearly

defined by the user. If the personnel in question is not

already in possession of the requisite know-how, appropriate

training and instructions must be provided. If deemed

necessary, the manufacturer/supplier will provide such

training and instructions at the user’s request. In addition, the

user is responsible for ensuring that the contents of these

operating instructions are fully understood by the personnel

in question.

3.3 Danger or non-observance of the safety

Instructions

Non-observance of the safety instructions may lead

to personal injury and also to danger for the

environment and the valve itself. Non-observance of these

safety instructions will also forfeit the user’s warranty.

Such noncompliance could, for example, result in:

- failure of essential functions of the valve/plant

- failure of prescribed maintenance and repair practices

- hazard to people by electrical, mechanical or chemical

effects

- hazard to the environment due to leakage of hazardous

substances

3.4 Safety consciousness

The safety instructions contained in this manual, the

applicable national accident prevention regulations and any

of the user’s own applicable internal work, operation or

safety instructions must be fully complied with.

3.5 Safety instructions for the user/operator

Any hot or cold parts of the valve (e.g. body or hand

wheel) that could pose a hazard must be protected

by the user against accidental contact.

Leakage (e.g. at the stem seal) of hazardous substances

(e.g. explosive, toxic, hot) must be drained so as to avoid all

danger to people or the environment. All relevant laws must

be observed.

Electrical hazards must be effectively prevented.

(For details, please refer to the VDE standards

and/or the local energy supply utility regulations).

3.6 Safety instructions for maintenance,

inspection and installation work

The user is responsible for ensuring that all

maintenance, inspection and installation work is

carried out by authorized, adequately qualified staff who are

thoroughly familiar with this instruction manual.

All work on a valve may only be performed when the valve is

un-pressurized and has cooled down. This means that the

temperature of the medium in all the valve’s chambers must

be lower than the vaporization point of the medium.

All work on actuated valves may only be done after the

actuator has been disconnected from its energy supply. The

procedure described in the operating instructions to shut

down the actuator must be observed.

Valves in contact with hazardous media must be

decontaminated.

Immediately following completion of the work, all safety

relevant and protective devices must be reinstalled and/or

reenabled.

Prior to recommissioning, refer to the points listed under

section 7, Commissioning.

3.7 Unauthorised modification and

manufacturing of spare parts

The equipment shall not be altered or modified in

any way prior to consultation with the manufacturer.

Genuine spare parts and accessories authorized by the

manufacturer will ensure operational safety. The

manufacturer cannot be held responsible for damage

resulting from the use of non-genuine parts or accessories.

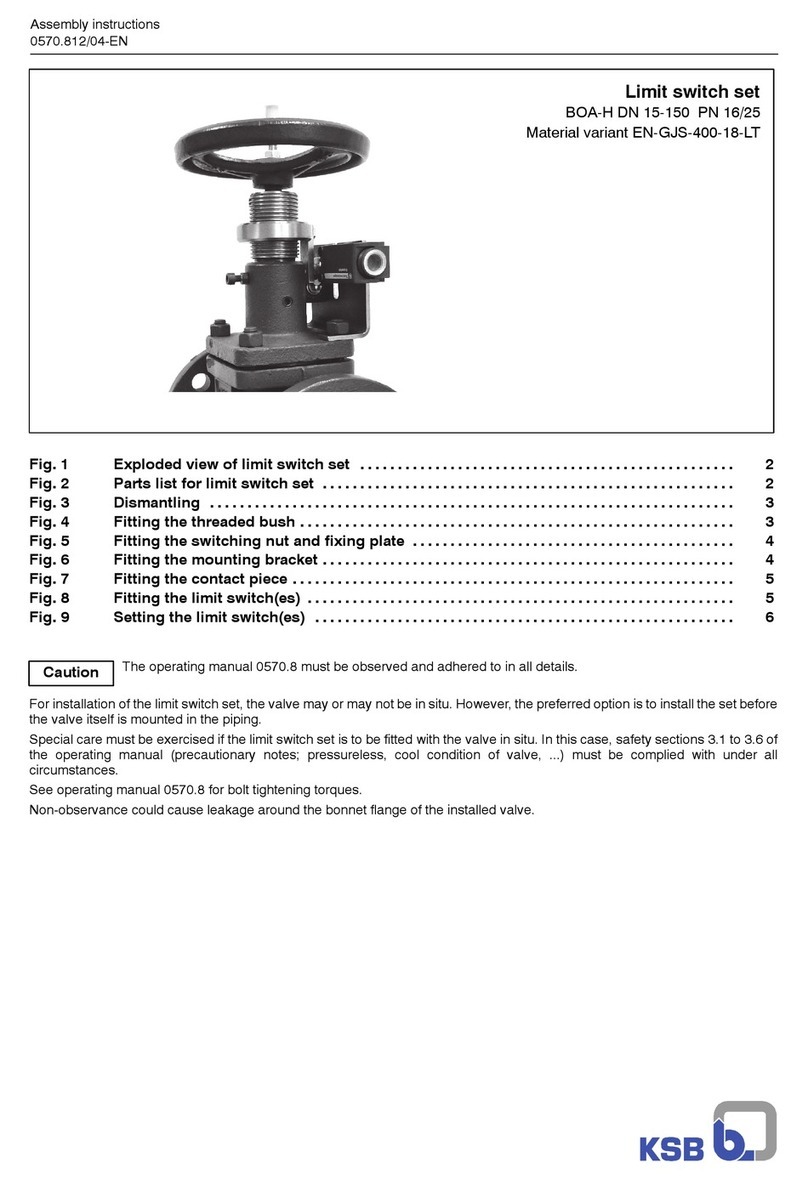

Caution