1 Supplementary Operating Manual

4 of 16 BACnet MS/TP Gateway

1 Supplementary Operating Manual

1.1 General

This supplementary operating manual accompanies the installation/operating

manual. All information contained in the installation/operating manual must be

observed.

Table1: Relevant operating manuals

Type series Reference number of the operating/installation

manual

PumpDrive 2 4074.81

1.2 Function

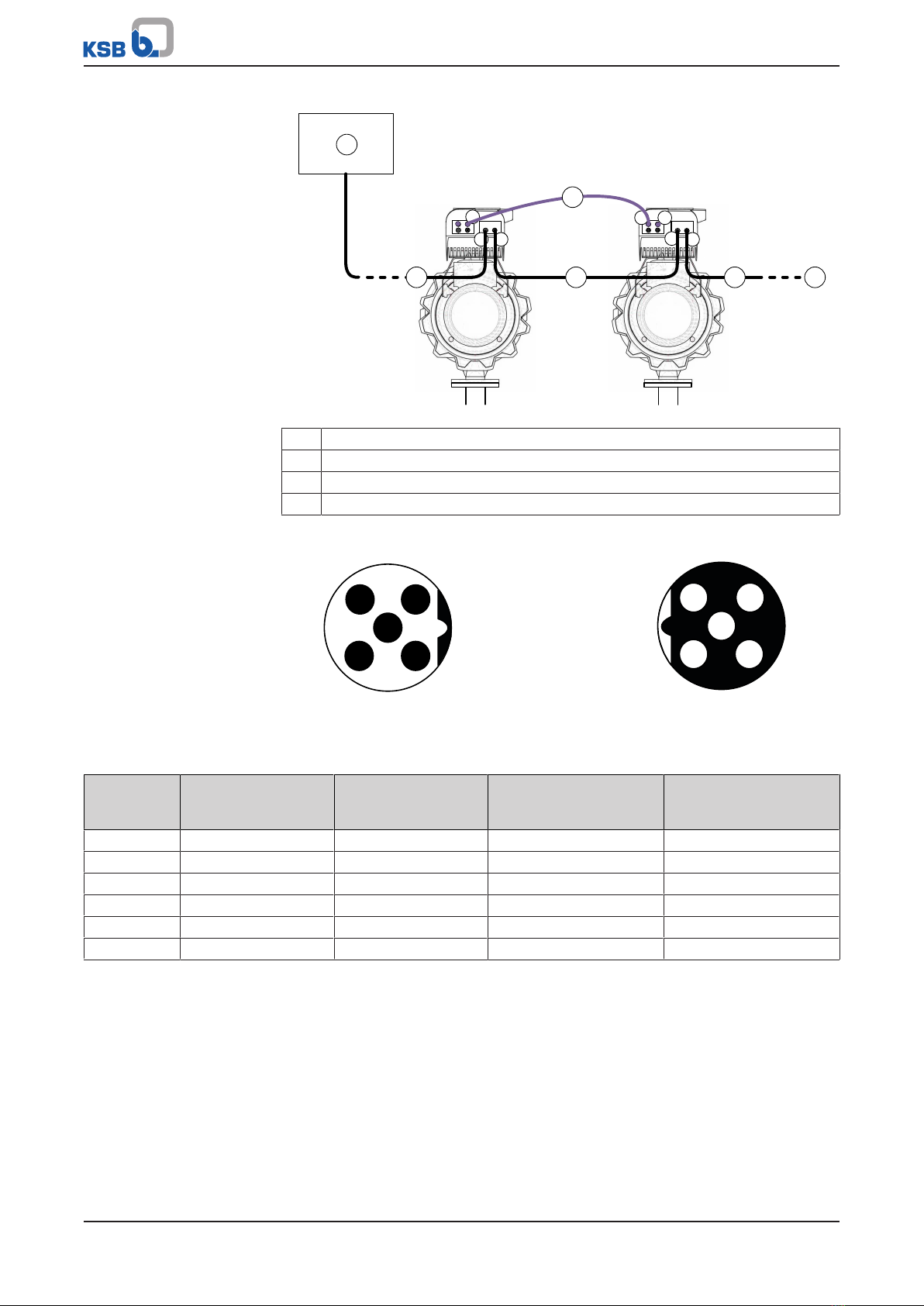

The BACnet MS/TP module is used to connect the frequency inverter to a BACnet MS/

TP network. A BACnet MS/TP module is required for monitoring and open-loop or

closed-loop control purposes for each frequency inverter in single-pump or multiple

pump configurations of up to 2 pump sets.

▪BACnet = Building Automation and Control Networks

▪MS/TP = Master-Slave/Token Passing

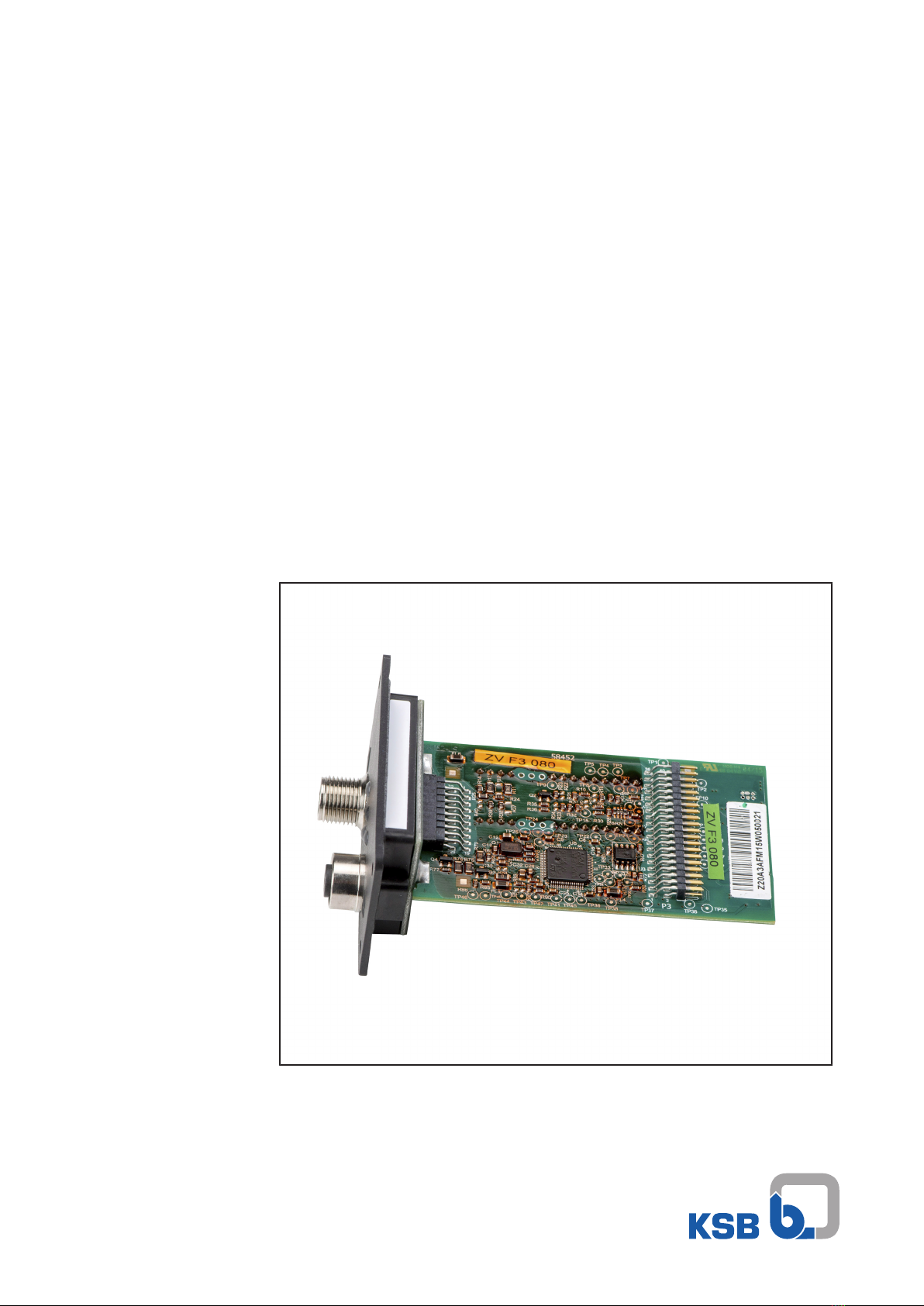

Interface The BACnet MS/TP module has a BACnet MS/TP interface.

Communication protocol BACnet MS/TP

Bus terminator External interface EIA-485 (RS 485)

Transmission rate 9600baud, 19200baud, 38400 baud,

57600baud, 115200 baud

Device type B-ASC

Information and downloads on BACnet are available online at http://www.big-

eu.org.

The BACnet MS/TP EIA-485 network cable should have the following properties:

▪Flexible

▪Shielded

▪Twisted wires for the data line

▪The wave impedance should be between 100 and 130 ohms.

▪For more details, see ANSI/ASHRAE standard 135, “Physical Layer” section.

Information on BACnet MS/TP and downloads for BACnet MS/TP are available online

at www.bacnet.org. For additional accessories for the BACnet MS/TP module (i.e.

M12 connectors and terminating resistors), see the type series booklet.

EDE lists

KSB provides an EDE file on the KSB web site for exchanging PumpDrive-specific

BACnet information. The EDE lists document all inbound and outbound objects with

the associated defined properties.

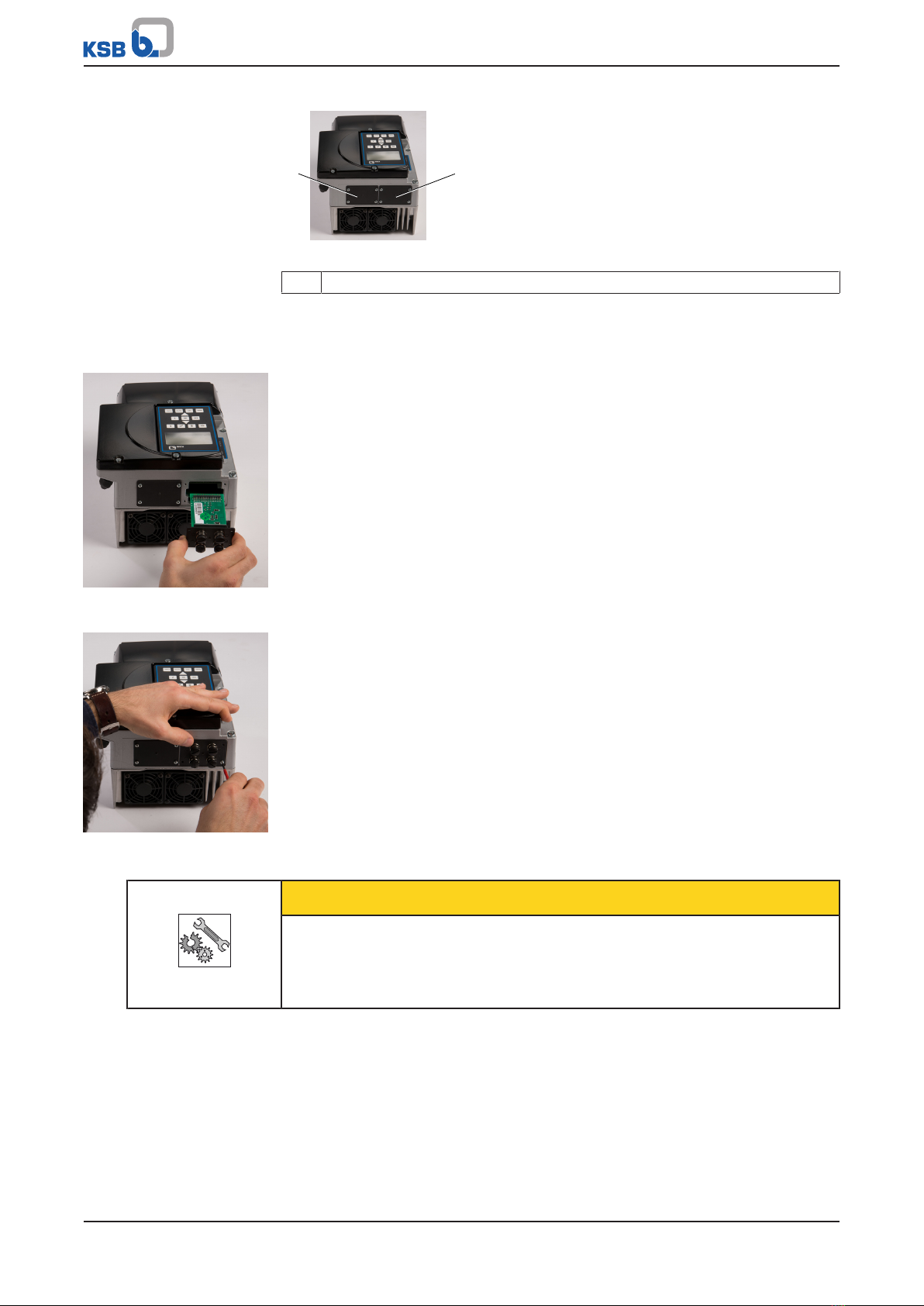

1.3 Field bus module connections

The field bus modules are plug-in modules.