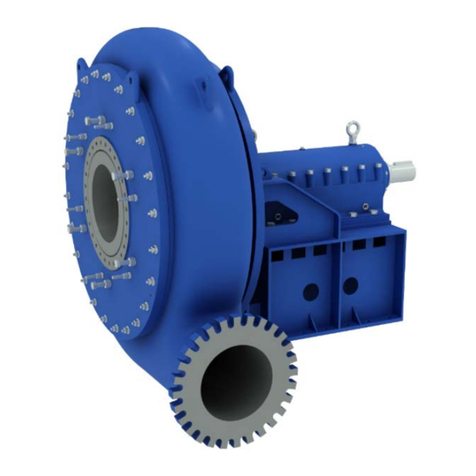

1 General

1.1 Principles

This manual is supplied as an integral part of the type series and variants indicated

on the front cover (for details, please refer to the table below).

Table 1: Variants covered by this manual

Pump

sizes

Impeller

types

Material variants

Cast iron Industrial materials

G G1 G2 GH H C1 C2

40-250 F, K, S F, K, S F,K F F, K F, K F, K F, K

80-250 E, F E, F F F F - - -

80-251 F F - - - - - -

80-315 D, E, F,

K

D, E, F,

K

D, F, K F F, K F, K F, K F, K

80-316 F F - - - - - -

100-240 F F F F F F F F

100-250 E, F, K E, F, K F, K F F, K F, K F, K F, K

100-251 D D D - - - - -

100-315 D, E, F,

K

D, E, F,

K

D, F, K F F, K F, K F, K F, K

100-316 D D D - - - - -

100-401 E, F, K E, F, K F, K F F, K F, K F, K F, K

150-251 D D D - - - - -

150-315 D, E, F,

K

D, E, F,

K

D, F, K F F, K F, K F, K F, K

150-400 D D D - - - - -

150-401 D, E, F,

K

D, E, F,

K

D, F F F,K F, K F, K F, K

151-401 K K K - K K K K

200-315 D, K D,K D, K - K K K K

200-316 K K - - K K K K

200-330 K K K - K K K K

200-400 D D D - - - - -

200-401 E, K E, K K - K K K K

250-400 D, K D,K D, K - K K K K

250-401 K K K - K K K K

300-400 D, K D, K D, K - K K K K

300-401 K K K - K K K K

This manual describes the proper and safe use of this equipment in all phases of

operation.

The name plate indicates the type series and size, the main operating data, the order

number and the order item number. The order number and order item number

clearly identify the pump set and serve as identification for all further business

processes.

In case of damage, immediately contact your nearest KSB Service centre to maintain

the right to claim under warranty.

1.2 Installation of partly completed machinery

To install partly completed machinery supplied by KSB, please refer to the sub-

sections under Servicing/Maintenance.

1 General

6 of 74 Amarex KRT

Goodnal STP ST041 Sewage Delivery (Amarex KRT Submersible Motor Pump) Vendor Manual