Amarex®N S 32-160

22

6.1.4 Operating voltage

Maximum admissible deviation of operating voltage:

+10 % for explosion-proof models

The maximum permissible voltage difference between the

individual phases is 1 %.

6.1.5 Densitiy of the fluid pumped

Max. density: 1.1. For higher densities please contact KSB.

6.2 Shutdown/storage/preservation

6.2.1 Storage of new pumps

-- Store the pump in a dry location in upright position and in its

original packaging. Support the electric cable at the cable

entry to prevent permanent deformation.

-- Spray-coat with oil the inside wall of the pump casing and in

particular the impeller clearance areas, and close the pump

nozzles (e.g. with plastic caps or similar).

6.2.2 Measures to be taken for prolonged shutdown

6.2.2.1 The pump remains installed

In order to make sure that the pump is always ready for instant

start-up, start the pump set regularly once every 3 months for a

short time (approx. 1 minute). Before doing so, make sure that

the fluid level in the sump or tank is above R1/R2.

6.2.2.2 The pump is removed from the sump and stored

Before putting the pump into storage, carry out all checks and

maintenance work specified in sections 7.1 and 7.2. Then apply

preservatives as described in section 6.2.1.

7 Servicing/maintenance

7.1 General instructions

A regular maintenance schedule will help avoid expensive

repairs and contribute to trouble-free, reliable operation of the

pump with a minimum of maintenance expenditure and work.

Work on the unit must only be carried out with

the electrical connections disconnected (incl.

control cable).

Pumps handling fluids posing health hazards must be

decontaminated. When draining the fluid see to it that

there is no risk to persons or the environment. All relevant laws

must be heeded.

7.2 Servicing/inspection

Servicing and maintenance work shall include the measu-

res listed in the table below. The work shall be performed

by qualified personnel only!

§Servicing operations Service interval

7.2.1 Insulation resistance test

7.2.2 Checking the power cable

7.2.3 Checking the monitoring de-

vices Every 4000 h, but at

7.2.4

7.4.3 Oil change least once a year

7.2.5 Bearings and lubrication

7.2.6 Visual inspection of lifting

chain / guide wire

General overhaul Every 5 years

In difficult operating conditions, maintenance intervals must be

reduced.

7.2.1 Insulation resistance test

Measurements must be taken at the cable ends (disconnected

in the control cabinet).

Measuring voltage: max. 500 V d.c.

The insulation resistance measured between phase and earth

must not be less than 5MΩ. If the resistance measured is lower,

cable and stator resistance must be measured separately to

locate the defect.

Measure cable resistance:

-- between phase and earth

-- between temperature sensors and earth

If the insulation resistance for the power cable is less than

5MΩ, the power cable is defective and must be replaced.

Measure motor resistance:

-- between phase and earth

-- between temperature sensors and earth

If the insulation resistance of the motor is lower than 5MΩ,the

winding is defective. We recommend to contact the motor

manufacturer or KSB Service.

7.2.2 Checking the power cable

-- Visual inspection

If the cable shows mechanically or chemically induced damage

such as scratches or blisters, the complete cable must be

replaced.

-- Checking the earth conductor

In a 10-metre cable, the resistance between the earth

conductor and earth must be less than 1 Ω.

7.2.3 Checking the monitoring devices

7.2.3.1 Temperature monitoring

-- In a 10-metre cable, the resistance between conductor ends

20 and 21 as well as 21 and 22 must be less than 1Ω.

7.2.4 Oil change

7.2.4.1 Draining the oil

When dismantling the motor section and the power cable make

sure that the conductors are clearly marked for future

reassembly.

For disassembly, please refer to the sectional drawing on

page 45.

1. Remove suction cover 162.

2. Undo and remove impeller fastening screw M8. The

impeller/shaft connection is a tapered fit.

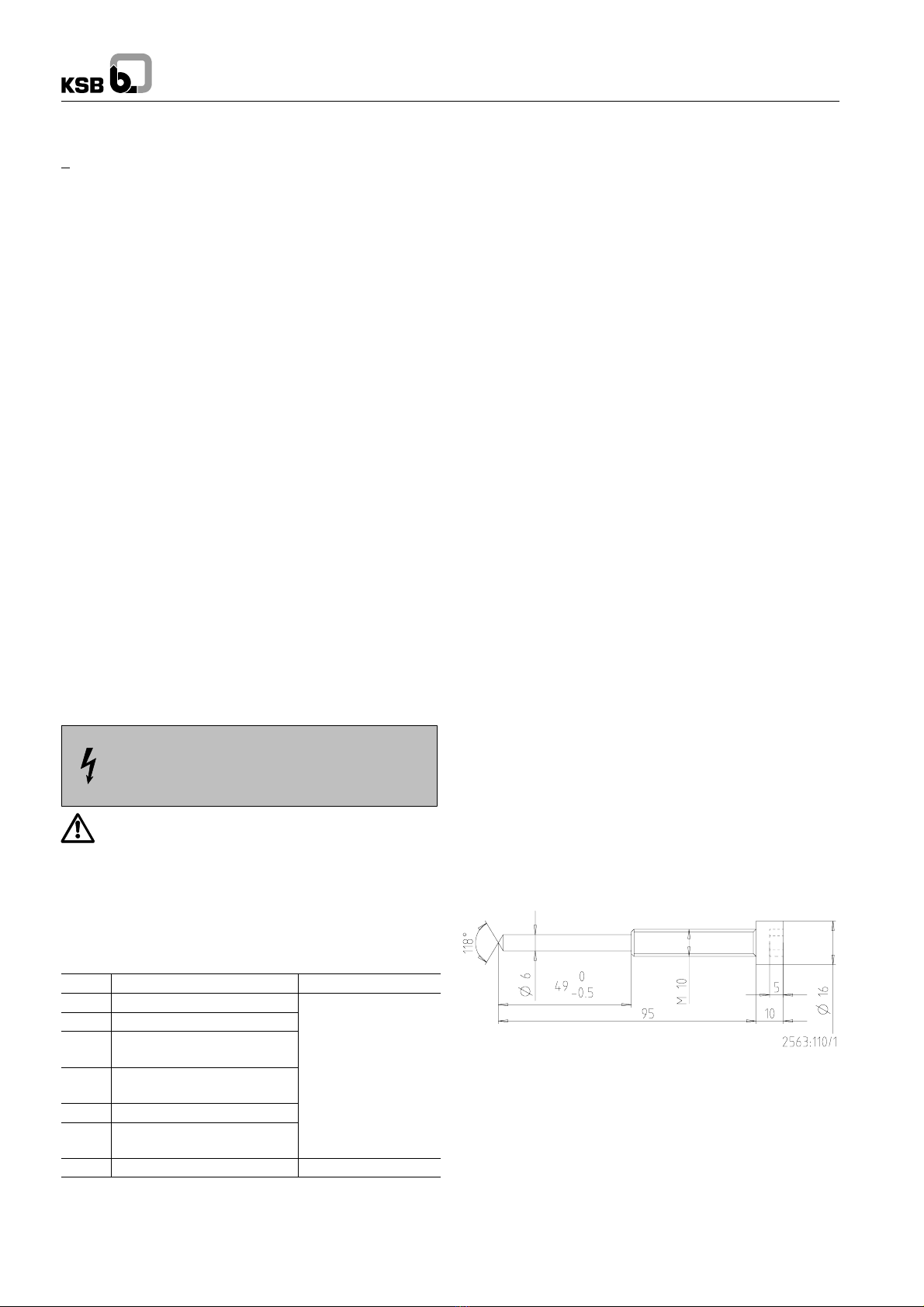

3. For dismantling the impeller, an M10 jacking thread is

provided at the impeller hub. Screw in the jack as shown in

the drawing below and remove the impeller.

Impeller removal kit: 39 022 760

4. Push mechanical seal 433.02 along the shaft.

5. Drain off the oil (see drawing below).