WKT

6

Additionally, the resulting rapid pressure build-up inside

the pump may cause excessive stresses on the pump

materials or even bursting.

The minimum flows indicated in section 6.4.5 refer to

water and water-like liquids. Longer operating periods

with these liquids and at the flow rates indicated will not

cause an additional increase in the temperatures on the

pump surface. However, if the physical properties of the

fluids handled are different from water, it is essential to

check if an additional heat build-up may occur and if the

minimum flow rate must therefore be increased. To

check, proceed as described in section 6.4.5.

In addition, the instructions given in section 6 of this

operating manual must be observed.

Both gland packings and mechanical seals may

exceed the specified temperature limits if run

dry. Dry running may not only result from an

inadequately filled seal chamber, but also from

excessive gas content in the fluid handled.

Pump operation outside its specified operating range

may also result in dry running.

In hazardous areas, gland packings shall only be

used if combined with a suitable temperature

monitoring device.

2.9.5 Temperature limits

In normal pump operation, the highest

temperatures are to be expected on the surface

of the pump and distributor casing, at the shaft seal and

in the bearing areas. The surface temperature at the

pump casing corresponds to the temperature of the fluid

handled.

If the pump is heated, it must be ensured that the

temperature classes stipulated for the plant are observed.

In the bearing bracket area, the unit surfaces must be

freely exposed to the atmosphere.

In any case, responsibility for compliance with the

specified fluid temperature (operating temperature)

lies with the plant operator. The maximum

permissible fluid temperature depends on the

temperature class to be complied with.

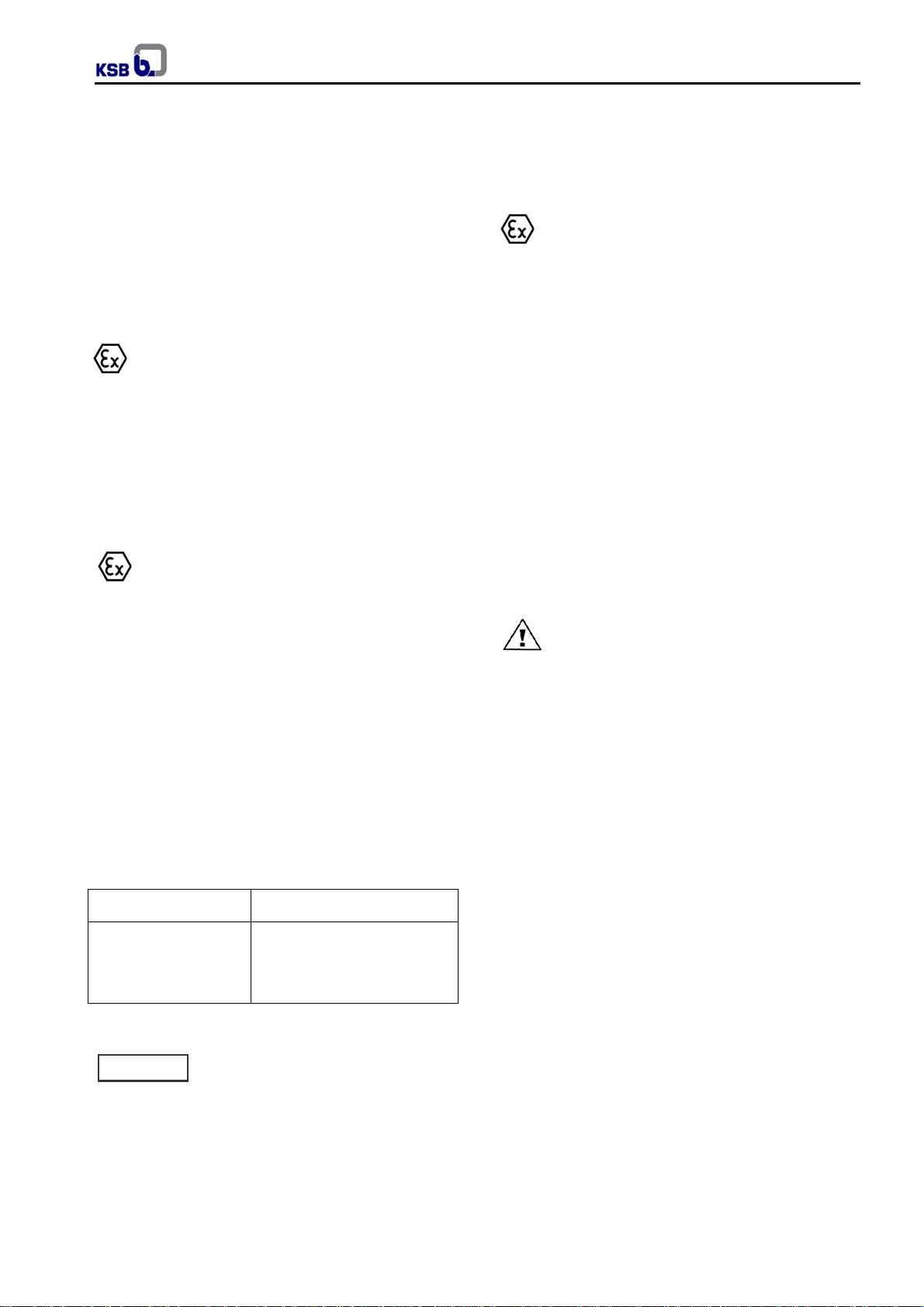

The table below lists the temperature classes to EN

13463-1 and the resulting theoretical temperature limits of

the fluid handled. In stipulating these temperatures, any

temperature rise in the shaft seal area has already been

taken into account.

Temperature class to

EN 13463-1: Temperature limit of

fluid handled

T5

T4

T3

T2

T1

85ºC

120ºC

185ºC

280ºC

Max. 400ºC *)

*) depending on material variant

Safety note: The permissible operating temperature of

the pump in question is indicated on the

data sheet. If the pump is to be operated at a higher

temperature, the data sheet is missing or if the pump is

part of a pool of pumps, the maximum permissible

operating temperature must be inquired from the pump

manufacturer.

Based on an ambient temperature of 40ºC and proper

maintenance and operation, compliance with temperature

class T4 is warranted in the area of the rolling element

bearings. A special design is required to comply with

temperature class T6 in the bearing area. In such cases,

and if ambient temperature exceeds 40ºC, contact the

manufacturer.

2.9.6 Maintenance

Only a pump unit which is properly serviced and

maintained in perfect technical condition will give

safe and reliable operation.

This also applies to the reliable function of the rolling

element bearings whose actual lifetime largely depends

on the operating mode and operating conditions.

Regular checks of the lubricant and the running noises

will prevent the risk of excessive temperatures as a result

of bearings running hot or defective bearing seals (also

see section 6.1.4).

The correct function of the shaft seal must be checked

regularly. Any auxiliary systems installed must be

monitored, if necessary, to make sure they function

correctly.

Gland packings must be tightened correctly, to prevent

excessive temperatures due to packings running hot.

3. Transport and interim storage

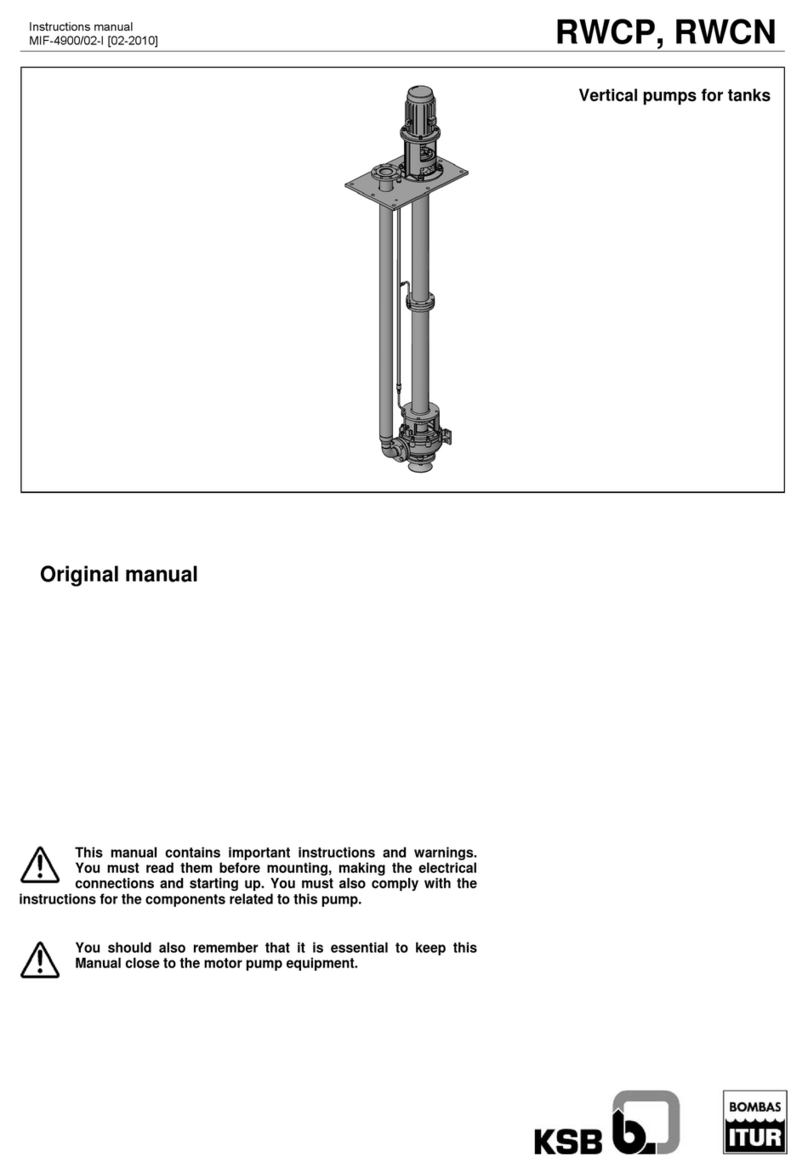

3.1 Transport

The transport of motor-pump set or only pump should be

made with ability and sound sense, according to safety

standards. By the motor eyebolt should only lift it, never

the motor-pump set.

If the pump / unit slips out of the suspension

arrangement, it may cause personal injury and

damage to property!

Vertical pumps up to about 4 m shipping length are

dispatched completely assembled. Larger pumps are

dispatched in sub-assemblies and must be assembled at

site under KSB´s supervision only.

The stuffing box is not packed and the packing is supplied

loose.

The barrel is normally supplied loose with the pump.

To avoid damage in transit, the motor is usually not

mounted before dispatch.

Please refer packing list received with the pump for more

details.

3.2 Interim storage (indoors) / Preservation

KSB standard storage and preservation procedures

maintain the pump protected for a maximum period of 6

months in an indoor installation. The unit / pump should

be stored in a dry room where the atmospheric humidity

is as constant as possible. When this period is exceeded,

additional storage procedure should be taken. For that,

please use the following conservation liquids:

-Internal parts of ferrous material in contact with

pumped liquid (except mechanical seal contact

surfaces): water repellent of mineral oil basis.

-Bearings: mineral oil for internal conservation.

-Polished parts: mineral oil for internal and external

conservation.

-Mechanical seals: should be cleaned by dry air. Do

not apply any liquid or other conservation material in

Caution