KTR-Group KTR-STOP XS A Series Manual

Other KTR-Group Industrial Equipment manuals

KTR-Group

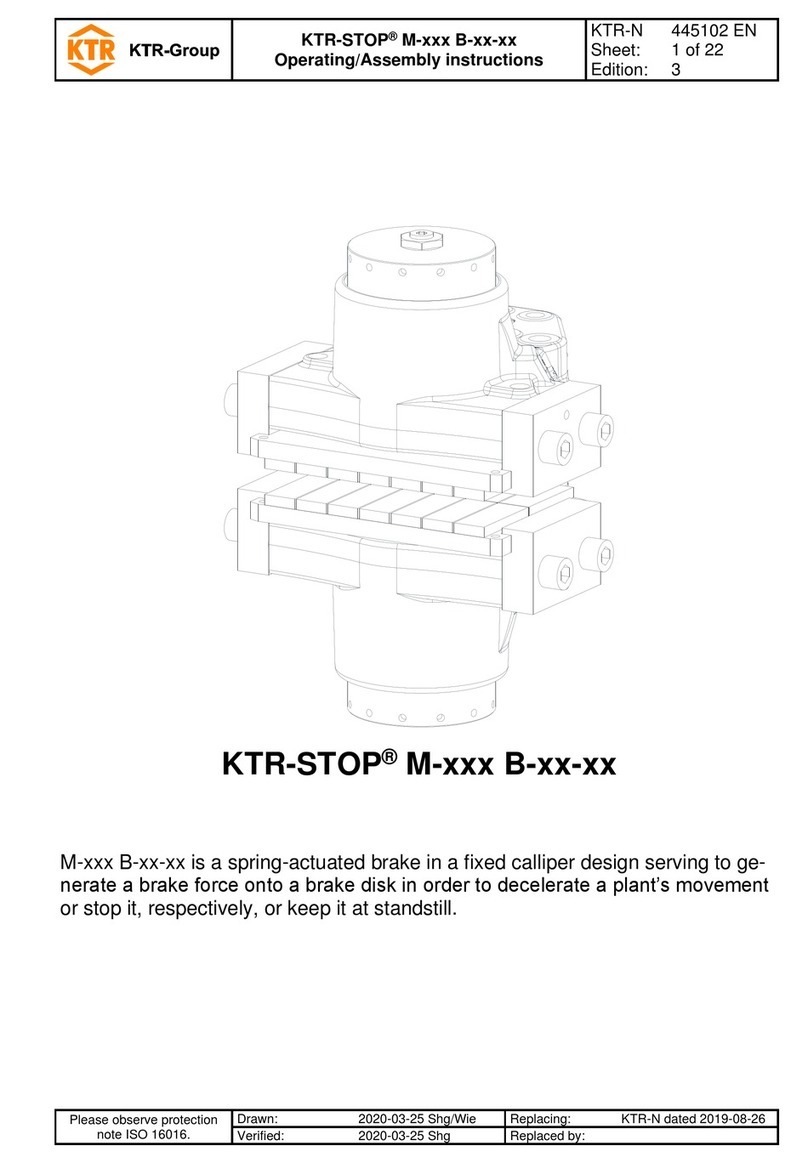

KTR-Group KTR-STOP M B Series Manual

KTR-Group

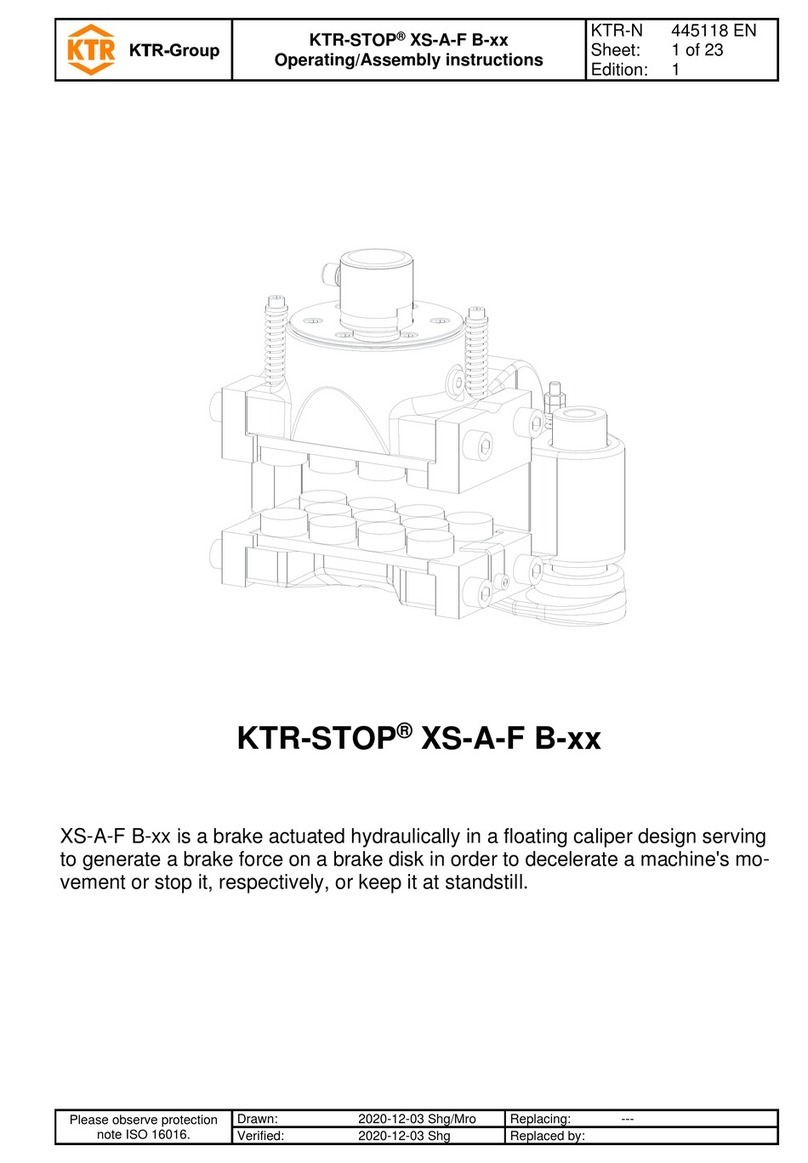

KTR-Group KTR-STOP XS-A-F B Series Manual

KTR-Group

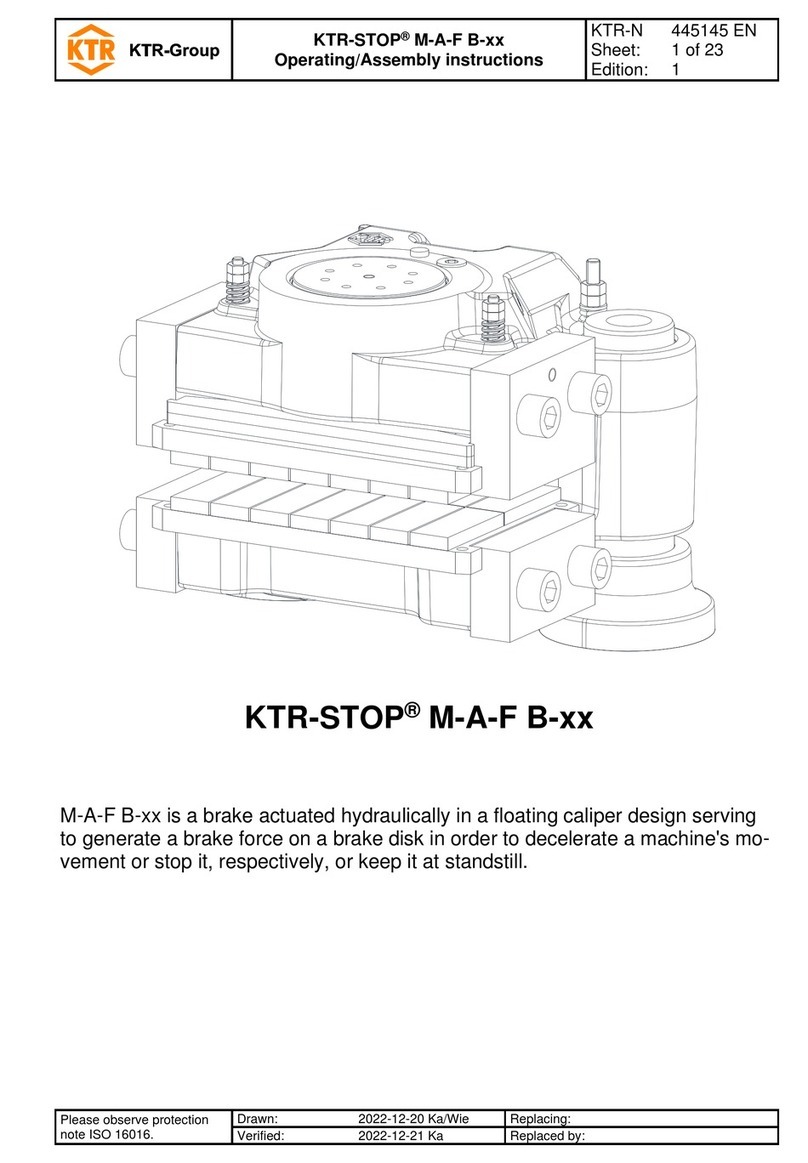

KTR-Group KTR-STOP M-A-F B Series Manual

KTR-Group

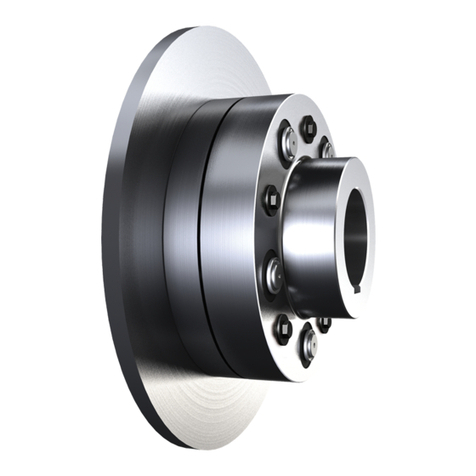

KTR-Group CLAMPEX KTR 150 Manual

KTR-Group

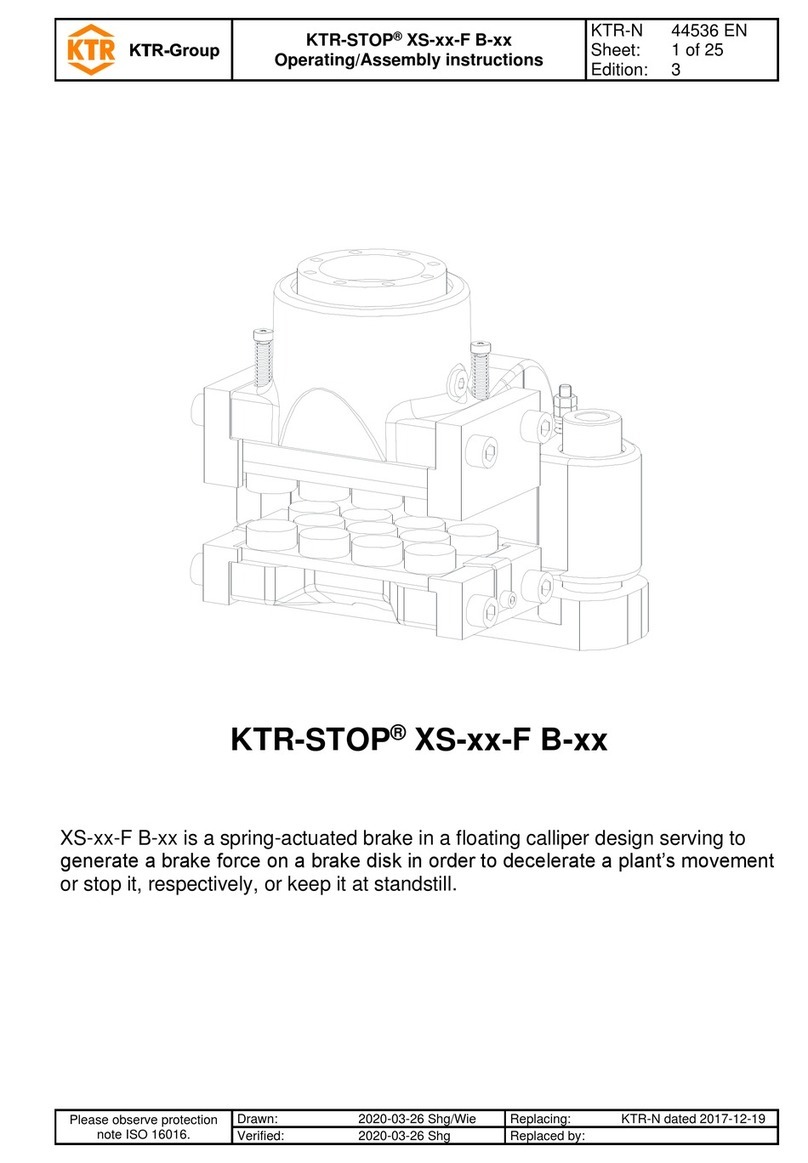

KTR-Group KTR-STOP XS F B Series Manual

KTR-Group

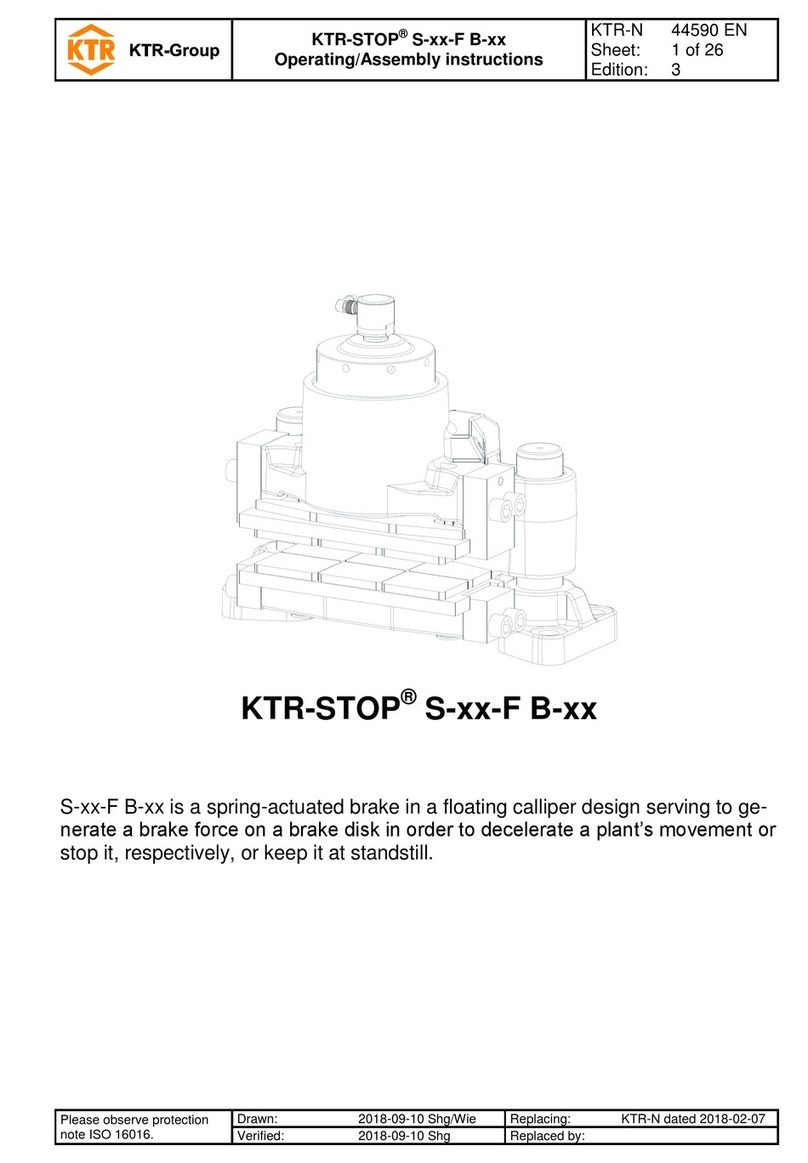

KTR-Group KTR-STOP S F B Series Manual

KTR-Group

KTR-Group REVOLEX KX Series Manual

KTR-Group

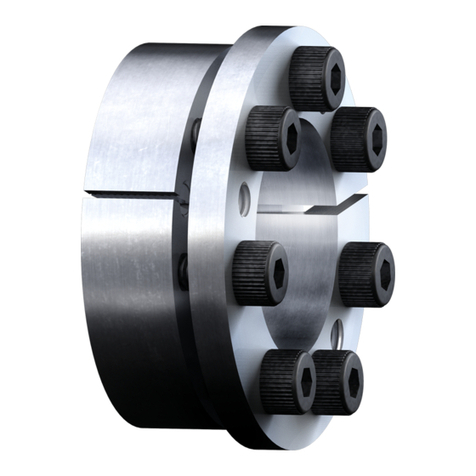

KTR-Group CLAMPEX 620 Manual

KTR-Group

KTR-Group CLAMPEX KTR 125 Manual

KTR-Group

KTR-Group BoWex M Series Manual

KTR-Group

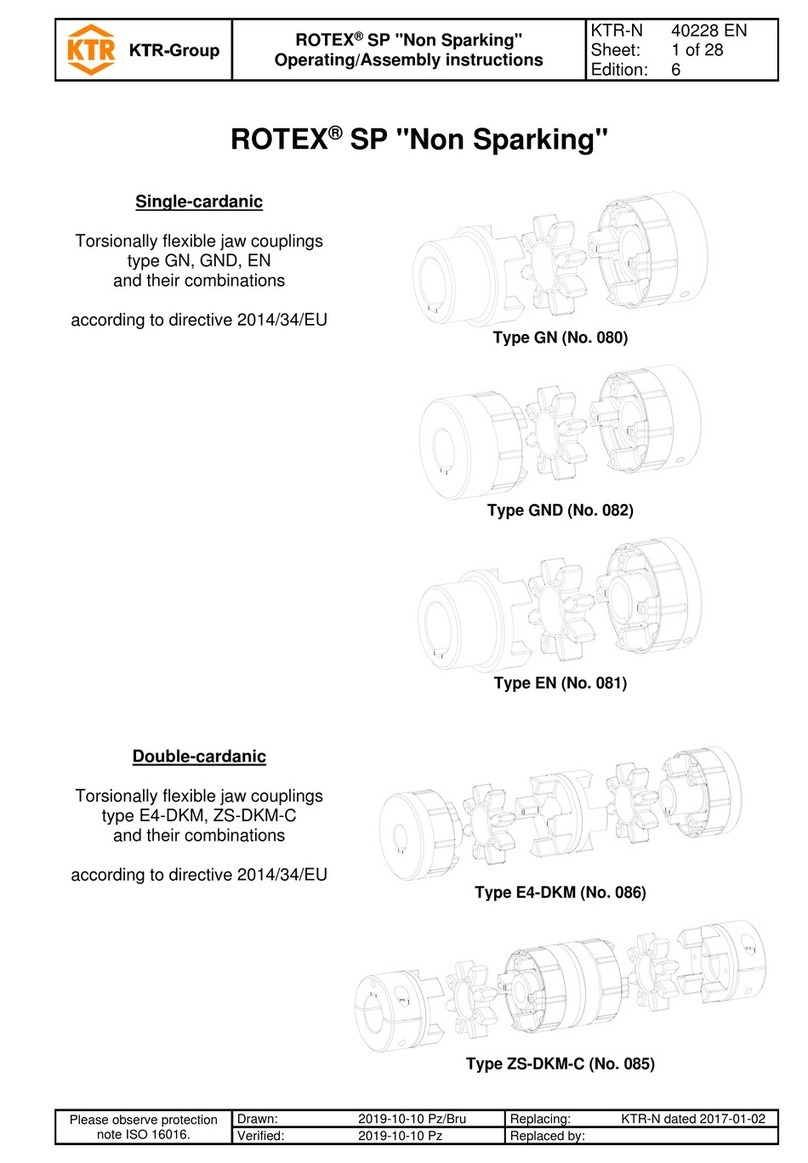

KTR-Group ROTEX SP Non Sparkling Manual

KTR-Group

KTR-Group KTR-STOP S-A-F B Series Manual

KTR-Group

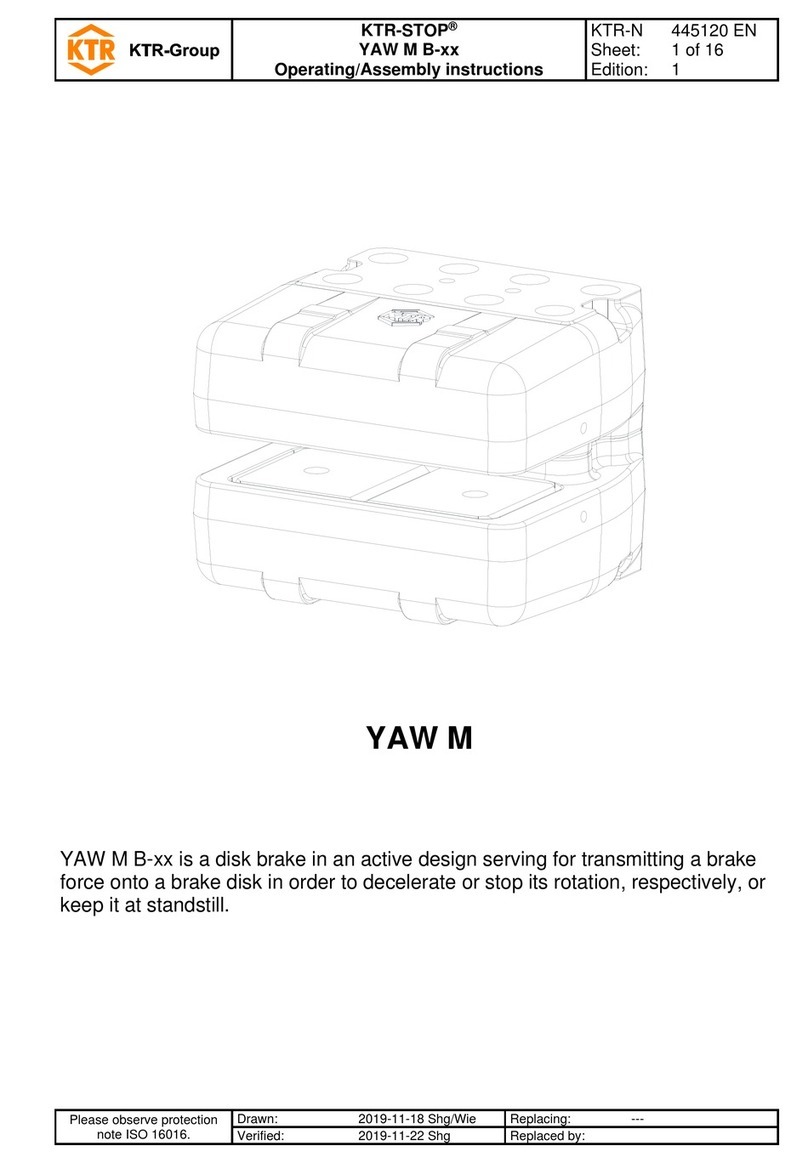

KTR-Group KTR-STOP YAW M B Series Manual

KTR-Group

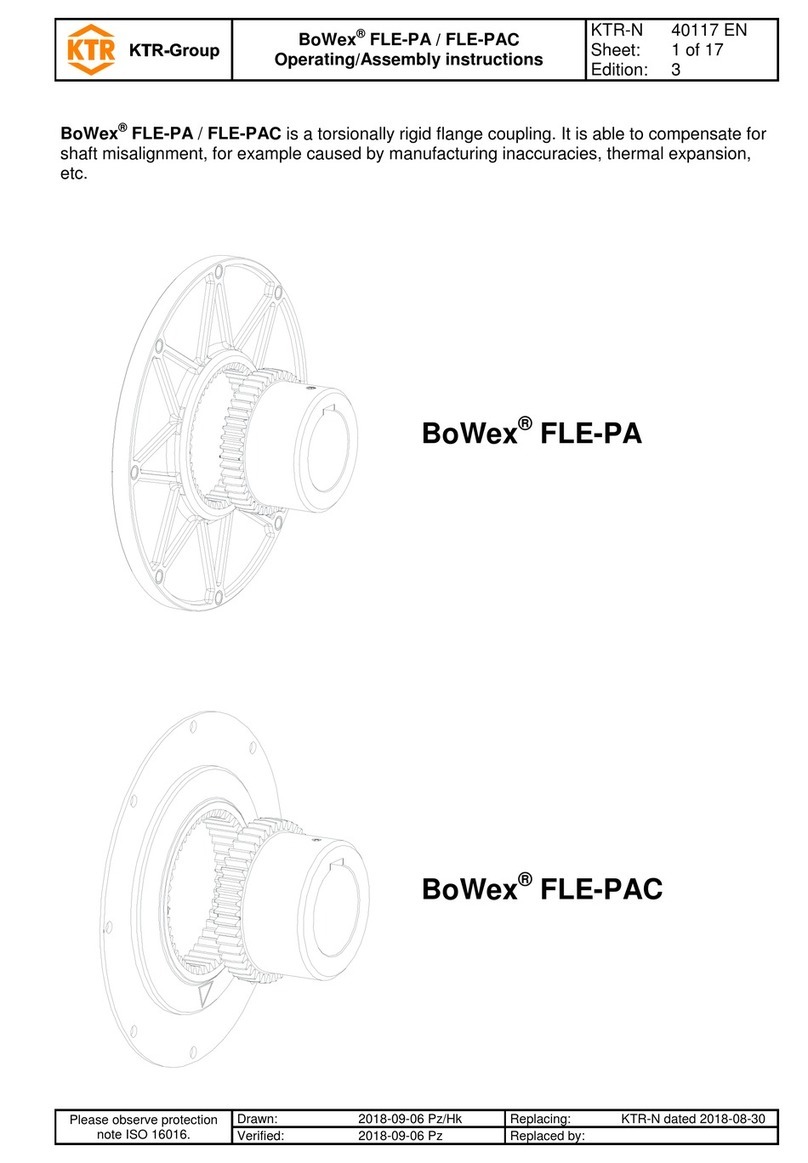

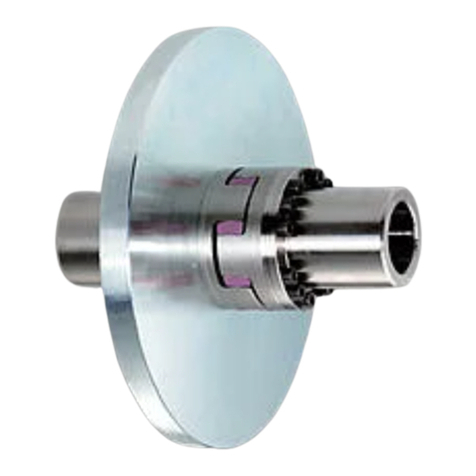

KTR-Group BoWex FLE-PA Manual

KTR-Group

KTR-Group RADEX-N Manual

KTR-Group

KTR-Group ROTEX 001 Manual

KTR-Group

KTR-Group ROTEX AFN-SB spec. Manual

KTR-Group

KTR-Group ROTEX GS Manual

KTR-Group

KTR-Group KTR-STOP TB Thuster Manual

KTR-Group

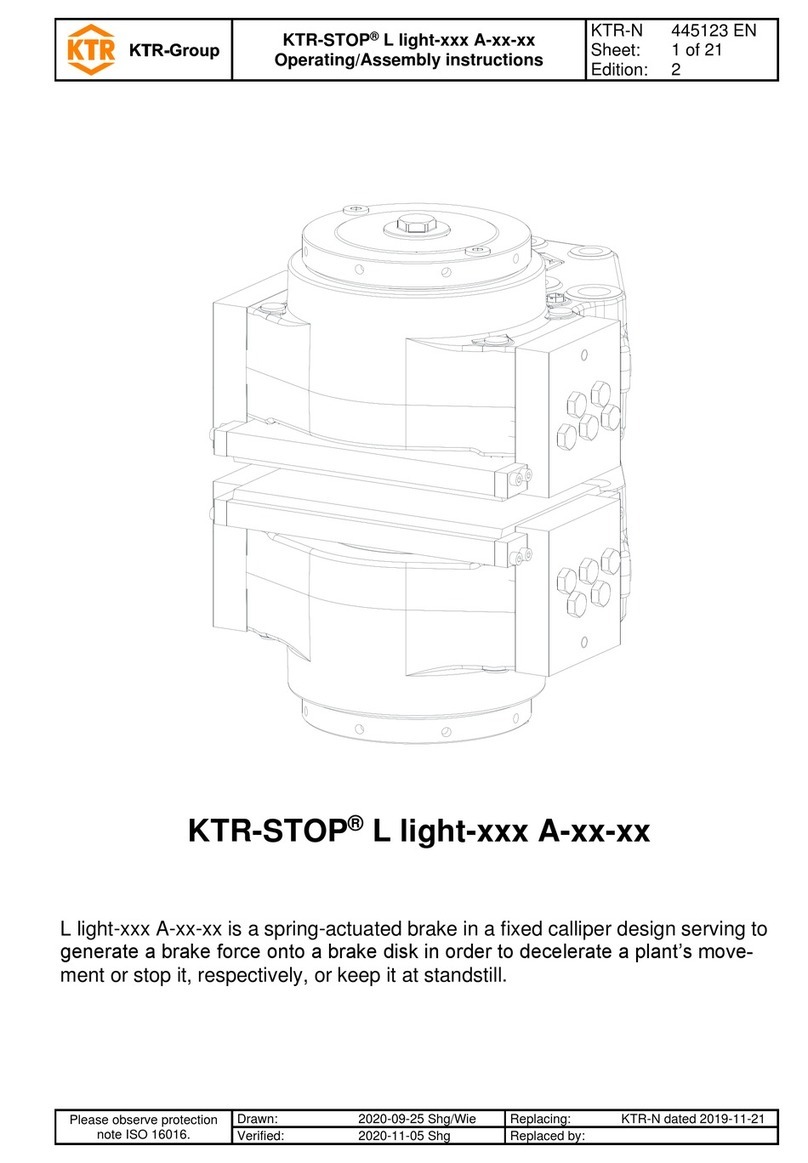

KTR-Group KTR-STOP L light A Series Manual