Table of contents

3

Table of contents

Preface ....................................................... 4

Target group for this operator’s manual 4

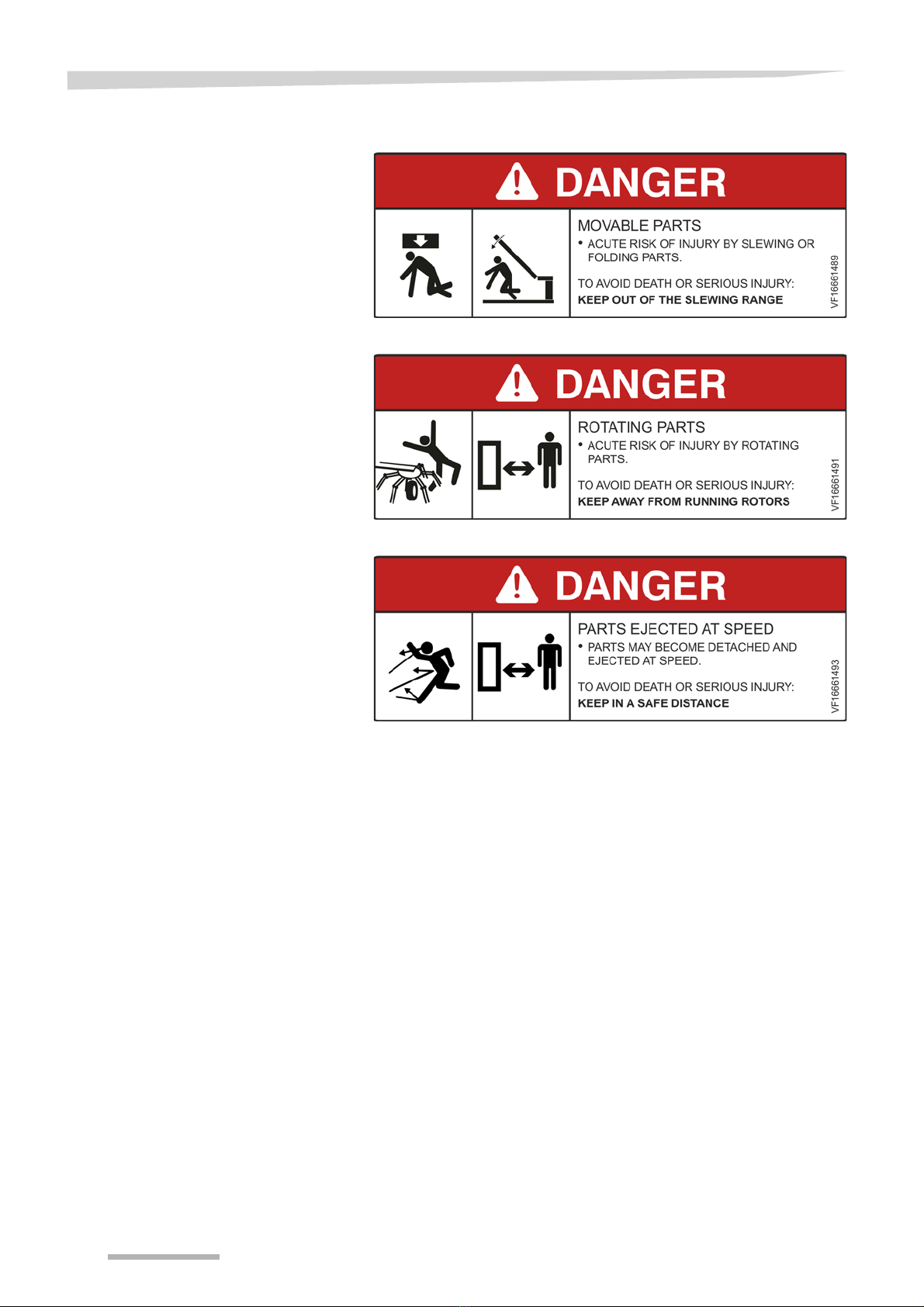

Symbols used 5

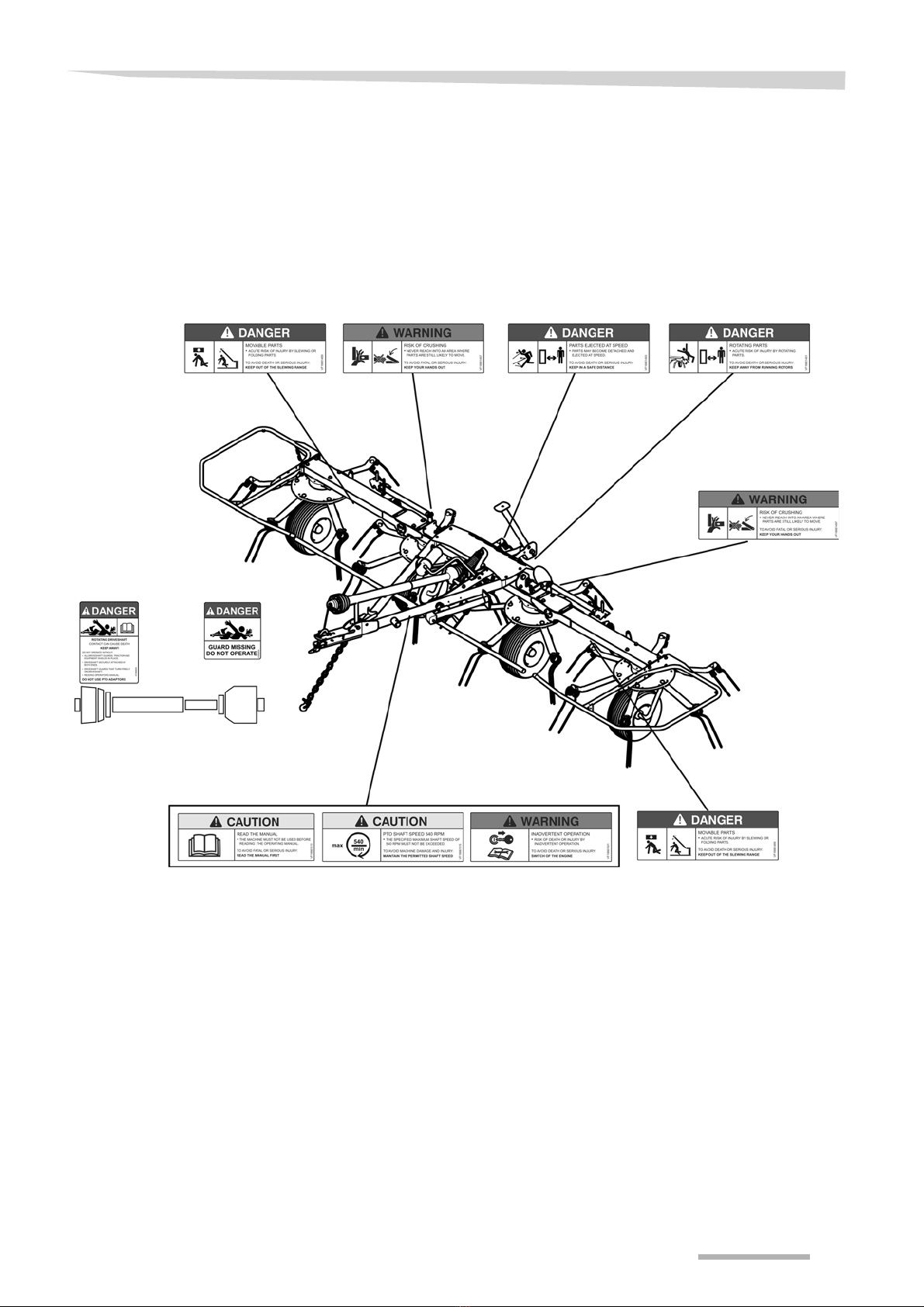

Safety ......................................................... 7

For your safety 8

Who is allowed to operate the machine? 16

General

safety information 16

Coupling 19

Hydraulics 20

Road transport 21

Operation 22

Uncoupling 23

Care and maintenance 24

Further regulations 25

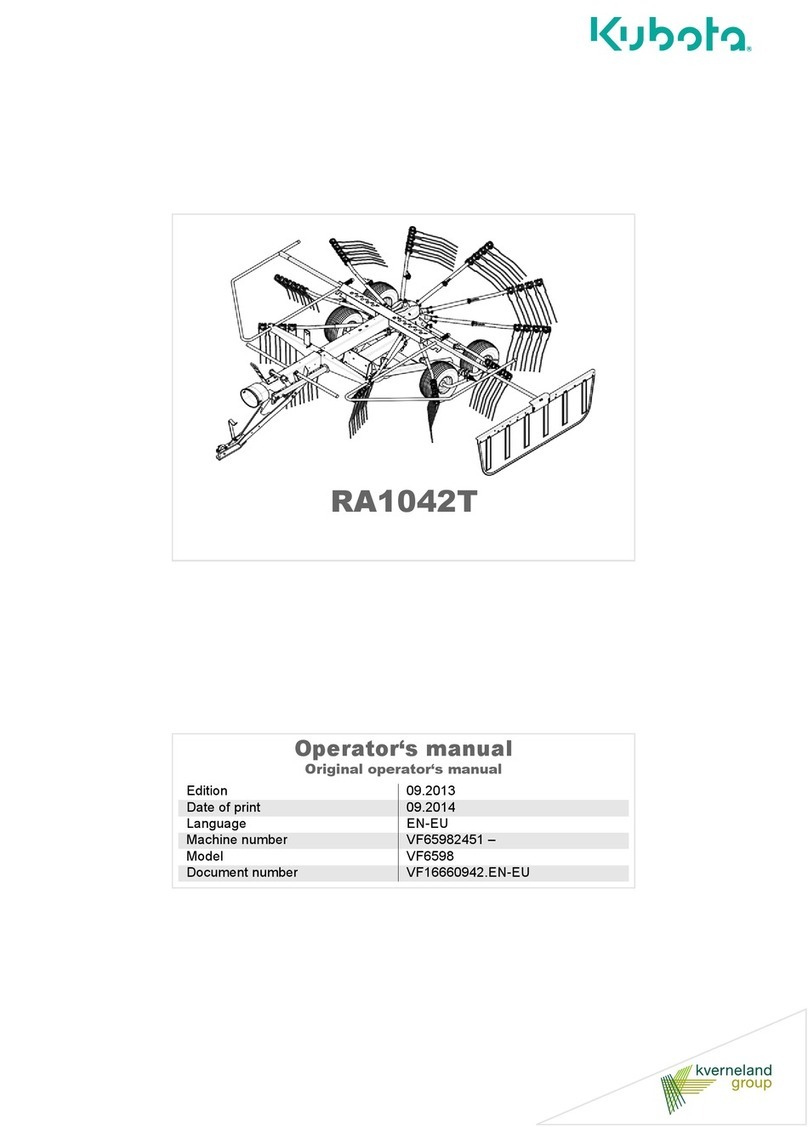

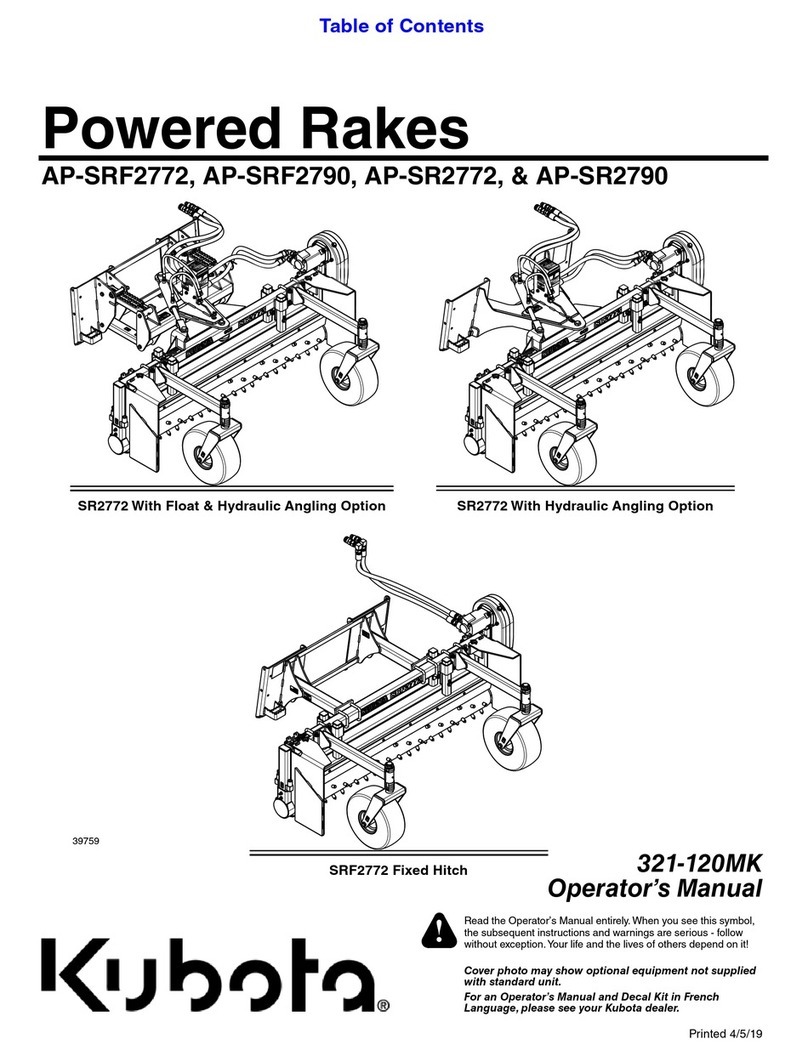

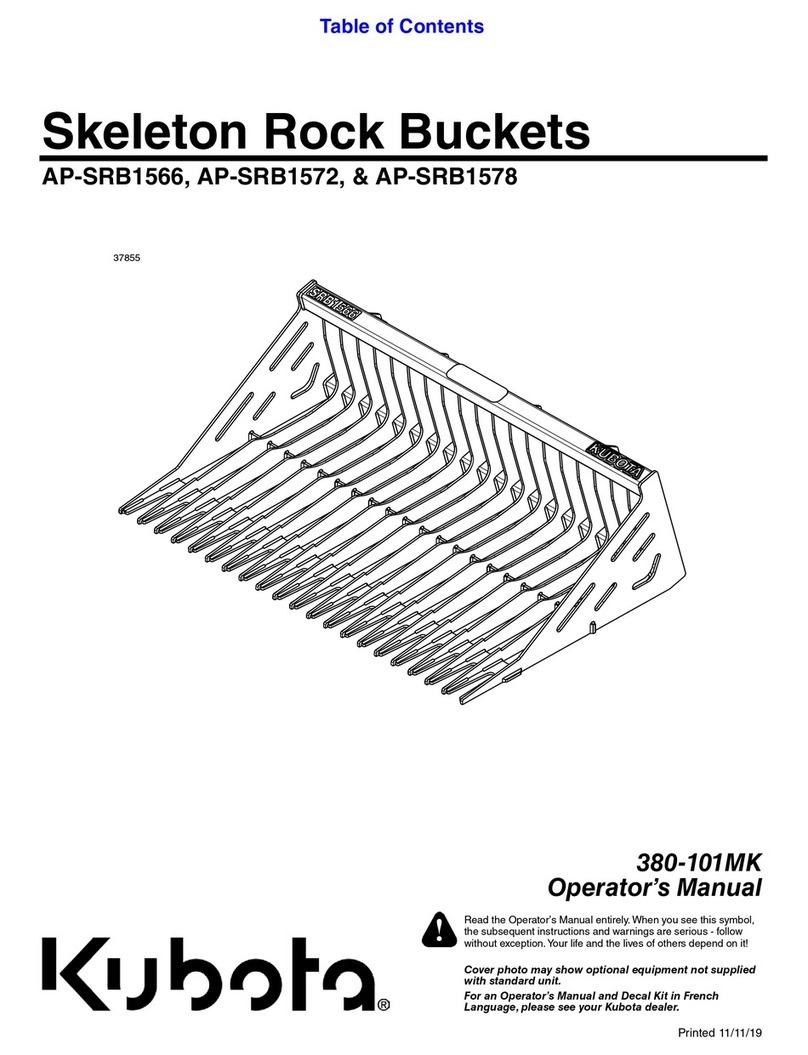

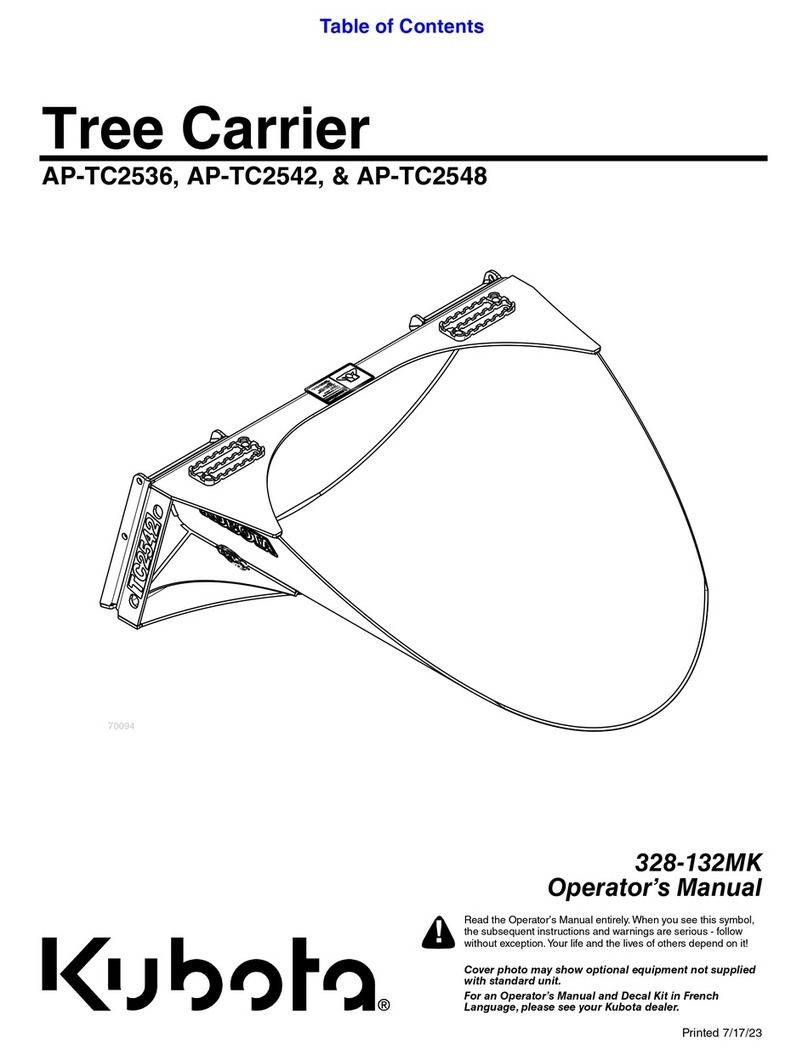

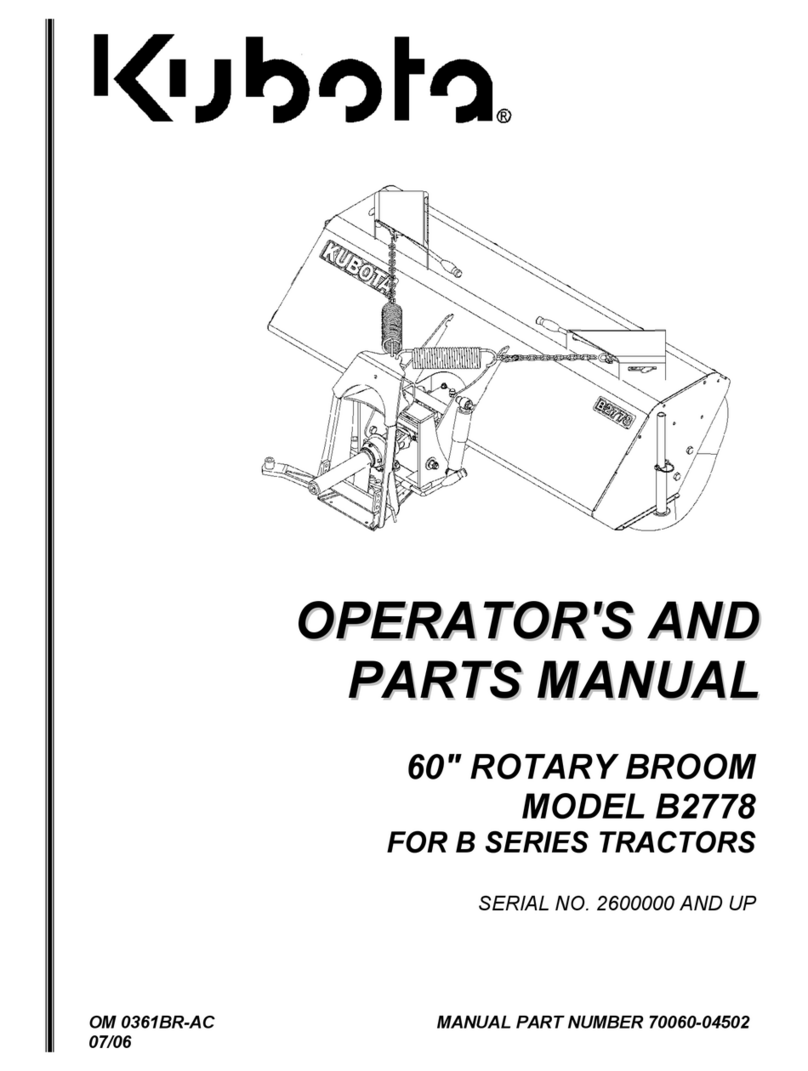

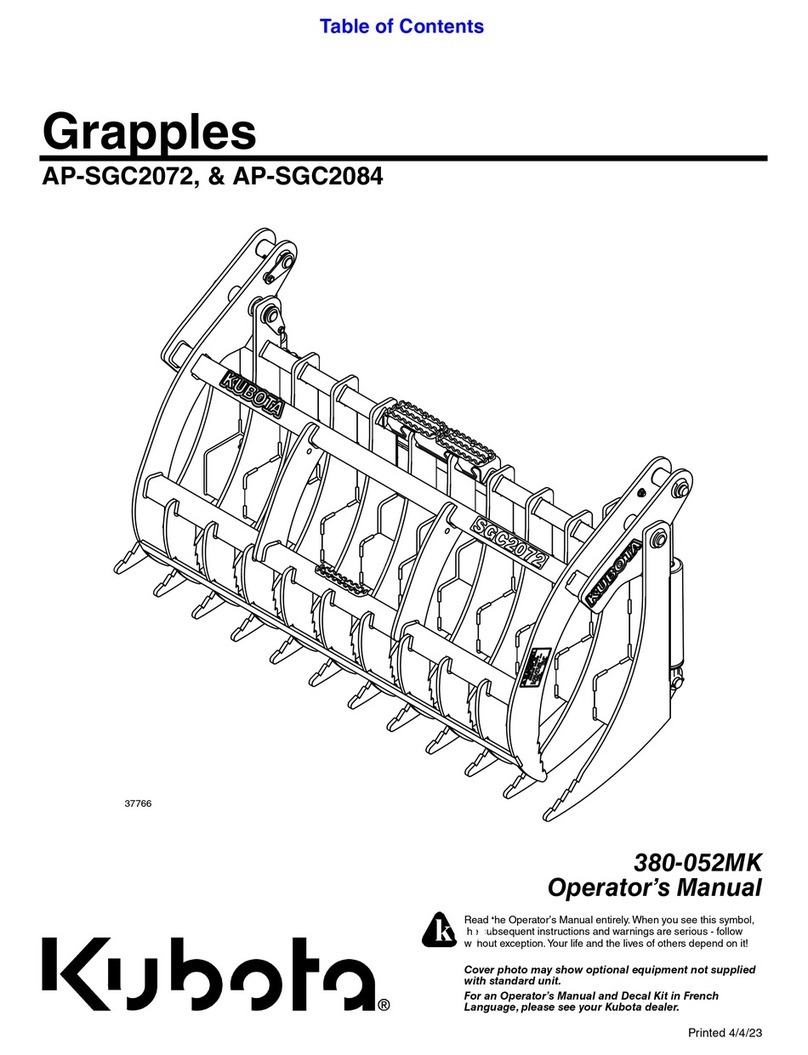

Getting to know the machine .................. 27

Range of application 27

Features 27

Designation of components 28

Technical specifications 29

Delivery and assembly ............................. 33

Checking the scope of delivery 33

Length of PTO shaft 34

Coupling the machine .............................. 36

Safety 36

General 36

Coupling the machine 37

Connecting the hydraulics 41

Preparing for use ...................................... 43

Safety 43

General 44

Folding the machine into the work position 44

Road transport .......................................... 46

Safety 46

General 47

Prior to road transport 47

Folding the machine into the transport position

48

Road transport 49

Preparations on the field ......................... 50

Safety 50

General 50

Folding the machine into the work position 51

Operation ................................................... 52

Safety 52

Crop processing 53

Use 54

Cleaning and care ..................................... 56

Safety 56

General 57

Cleaning 57

Care 57

Parking and storage .................................. 58

Safety 58

General 59

Uncoupling the machine 60

After the end of the season 60

Maintenance ............................................... 61

Safety 61

General 62

Screwed connections 65

Lubrication points for grease lubrication 67

Lubrication points for oil lubrication 68

Filling quantities 69

Lubricating the PTO shafts 70

Tyres 71

Hydraulics 72

Accessories ............................................... 73

Accessories 73

Fault elimination ........................................ 74

Troubleshooting 74

Circuit diagrams ........................................ 75

Hydraulic diagram 75

Decommissioning ..................................... 76

Environment 76

Index ........................................................... 77