Lipco KSM 130 User manual

Instructions

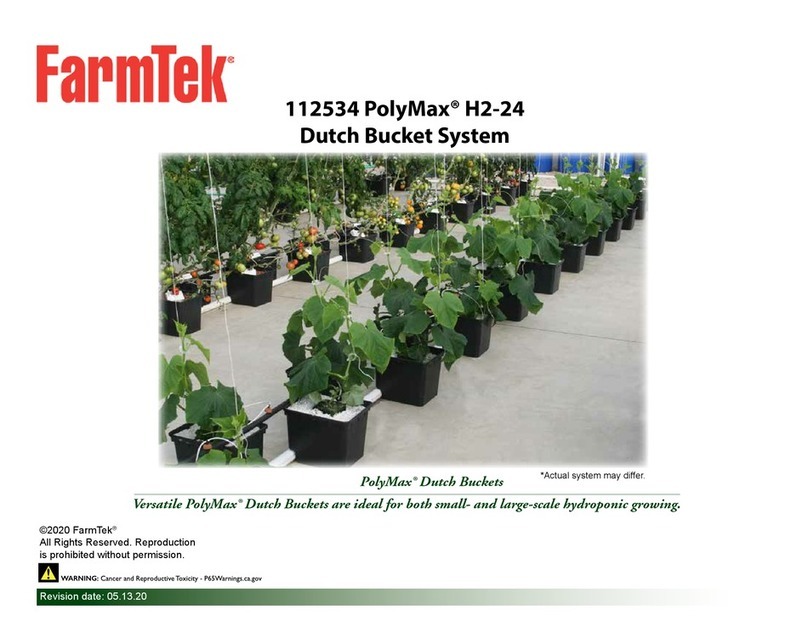

Compact disc mower KSM 130

2 - 22

140050-01-EN BA KSM 130 / 04.06.2020

1. Introduction

Dear Customer,

We thank you for having chosen a LIPCO Compact disc mower KSM

130. We hope that you will be happy with your choice.

In order that your LIPCO Compact disc mower KSM 130 will serve you

well for many years, we ask you to pay close attention to the operating

instructions which you will find in this manual. This will help you to

prevent breakdowns and accidents resulting from non-observance of

the operating instructions, for which our company will not accept

responsibility.

This Instruction and Maintenance Manual is to be considered an

integral part of the machine itself and therefore it must always

accompany the machine when it is sold, even in the event of its sale

to third parties.

If you keep this manual in a safe place and in good condition, you -

and whoever must use the machine - will be able to have a complete

reference on hand at all times.

Note:

The illustrations, descriptions and specifications in this manual are not

binding. LIPCO reserves the right to make modifications without

notice.

Instructions

Compact disc mower KSM 130

3 - 22

140050-01-EN BA KSM 130 / 04.06.2020

2. Contents page

1. Introduction 2

2. Contents 3

3. Designated use 4

4. Warning signs attached to the machine 5

5. Safety regulations 6

6. Accident prevention 7

7. Connection to the engine-driven machine 10

8. Technical Data 12

9. Operation of the cutter bar / prior to mowing 13

10. Operation of the cutter bar / after mowing 13

11. Maintenance 14

12. Oil change 16

13. Cutting operation faults 17

14. Instructions for repair shops 18

15. After use 19

16. Warranty 20

17. EC Declaration of Conformity 21

Instructions

Compact disc mower KSM 130

4 - 22

140050-01-EN BA KSM 130 / 04.06.2020

3. Designated use

The LIPCO Compact disc mower KSM 130, when connected to single

axle tractors / power movers, is designed to mow grassland and

meadows.

Any other use for purposes other than those described here is

considered contrary to the designated use. The manufacturer cannot

be held liable for damage resulting from such use; the risk for such

use lies entirely with the user.

Operating the unit within the limits of its designated use also means

following the instructions for operation, transport and maintenance

described by the manufacturer.

Any work, maintenance and repair on the LIPCO Compact disc mower

KSM 130 must be carried out by persons who are familiar with the unit

and have been informed about possible risks!

The relevant accident prevention regulations as well as the other

generally recognised maintenance, safety, industrial medicine and

road traffic rules and instructions must be observed.

The manufacturer cannot be held liable for damage resulting from

unauthorised modifications of the LIPCO Compact disc mower KSM

130.

Instructions

Compact disc mower KSM 130

5 - 22

140050-01-EN BA KSM 130 / 04.06.2020

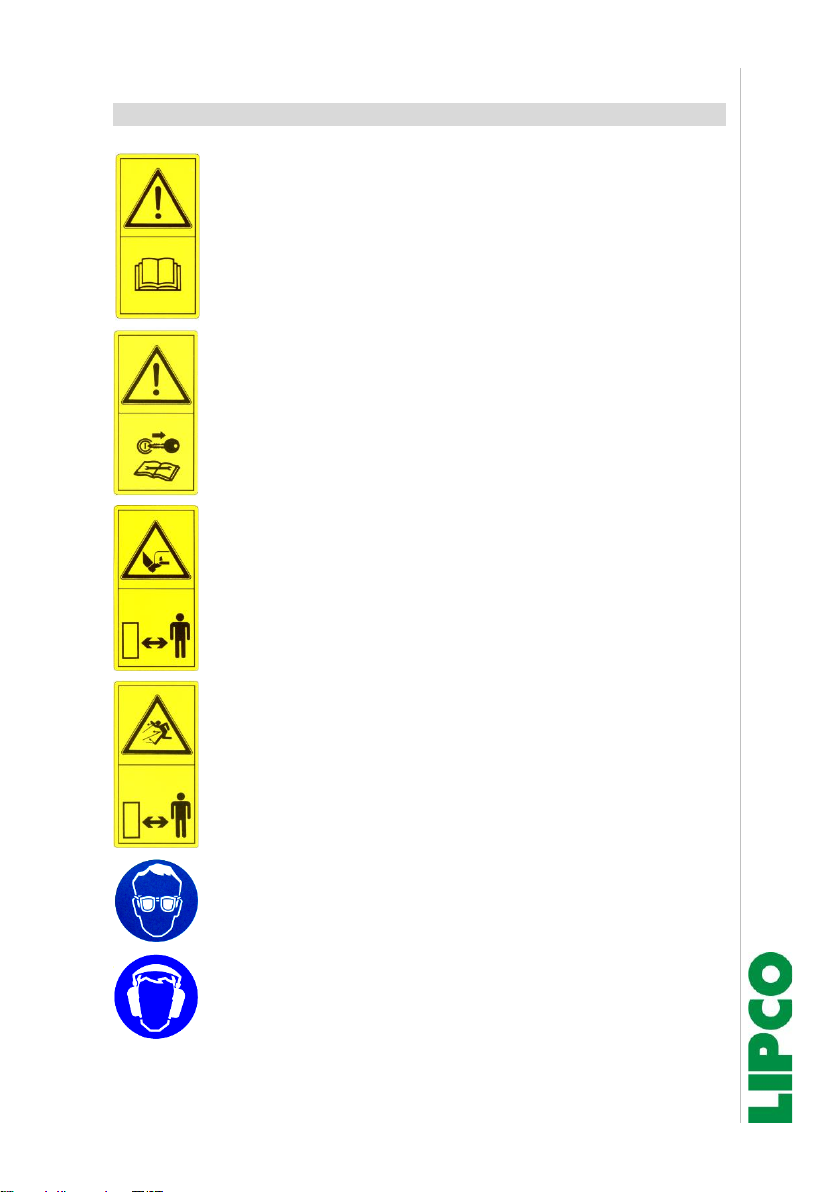

4. Warning signs attached to the machine

Before starting operation, the personnel must have

read the operating and safety instructions and must

observe them.

Before commencing maintenance and repair work,

switch off the engine and pull the key.

With the drive switched on and the tractor motor

running, maintain sufficient distance to rotating tools.

With the motor running, there is a risk of parts being

hurled away –maintain safety distance.

Wear eye protection.

Wear ear protectors.

Instructions

Compact disc mower KSM 130

6 - 22

140050-01-EN BA KSM 130 / 04.06.2020

5. Safety regulations

The operation of machines with rotating and moving parts always

bears risks. Please always follow the safety regulations:

•Before starting operation, the personnel must have read the

operating and safety instructions and observe them.

•Never remove or alter the safety devices!

•Do not touch rotating or moving parts!

•Never lie down beneath the unit for repair or control purposes

when the unit has not been carefully secured beforehand!

•Use the machine only in technically perfect condition!

•For maintenance work switch off the device!

•Maintain safety distance! (Attach danger sign on the side of the

machine)

•Any work, maintenance and repair on the LIPCO Compact disc

mower must be carried out by persons who are familiar with the

unit and have been informed about possible risks!

•The relevant accident prevention regulations as well as the other

generally recognised maintenance, safety, industrial medicine

and road traffic rules and instructions must be observed!

•The warnings and signs attached to the unit give important

information on safe operation; observing these instructions

ensures your safety!

Instructions

Compact disc mower KSM 130

7 - 22

140050-01-EN BA KSM 130 / 04.06.2020

6. Accident prevention

•Before starting the machine and the tractor check, road and

operating safety!

•Please observe, apart from the instructions given in these

operating instructions, also the generally applicable safety and

accident prevention regulations!

•The warnings and signs attached to the unit give important

information on safe operation; observing these instructions

ensures your safety!

•Before commencing work, familiarize yourself with all devices and

operating elements and their functions!

•Never stay in the rotating and pivoting area of the unit!

•Before leaving the engine-driven machine, switch off engine and

pull the ignition key, if present.

•Nobody is allowed to stay between the engine-driven machine and

the unit!

•Before working or continuing work with the unit, any damage must

be repaired!

•Check oil levels / lubrications!

•Wear ear protection and safety goggles!

•When connecting the unit, it is absolutely necessary that the

connecting flanges (drives) of single axle tractor/power mower

and the unit coincide or are made to coincide!

•Before switching on the engine-driven machine/power takeoff

shaft, make sure nobody is in the danger area of the unit!

Take into account the direction of rotation of the power takeoff!

Instructions

Compact disc mower KSM 130

8 - 22

140050-01-EN BA KSM 130 / 04.06.2020

•Driving behaviour, steering and braking capabilities are affected

by attached units and ballast weights! Ensure sufficient steering

and braking capabilities!

•Prior to maintenance and repair work on the lifted unit, secure it

by mechanical means using suitable supporting elements! Turn

off the engine and pull the ignition key!

•Check nuts and screws for tight seat and, if necessary, retighten

them. First check after about 5 operating hours.

•Spare parts must at least comply with the technical requirements

specified by the manufacturer! This is only guaranteed for LIPCO

original spare parts!

•A safe operation of the cutter bar can only be guaranteed if the

blades have been mounted according to regulations. For

mounting, the special tools included in the delivery must be used!

•Check cutter system before each startup for damaged, missing

and worn-out blades and, if necessary, replace them!

•Replace missing and damaged blades always in sets, to avoid the

formation of dangerous imbalances!

•The protection devices must be checked regularly, and worn-out

or damaged protection devices must be replaced!

•The protective devices on the cutter system, for example cloths

and hoods, protect against flying rocks and the like and protect the

access to dangerous places! This is why they must be put into the

protective position before commencing work!

•Prior to startup and during work, the sliding blocks must lie on the

ground!

Instructions

Compact disc mower KSM 130

9 - 22

140050-01-EN BA KSM 130 / 04.06.2020

•While the engine of the engine-driven vehicle is running, nobody

must stay in the working/danger area of the cutter system!

•Even when the cutter system is operated according to its

designated use, rocks and the like can be hurled away. Therefore

nobody must stay in the danger zone (about 30 m). Caution is

called for when working close to streets and buildings!

•After switching off the drive, the tools of the cutter system run on

for a certain period. Approach them only after they have come to

a halt!

•After driving onto an obstacle, immediately switch off the cutter

system and check it for damage!

Instructions

Compact disc mower KSM 130

10 - 22

140050-01-EN BA KSM 130 / 04.06.2020

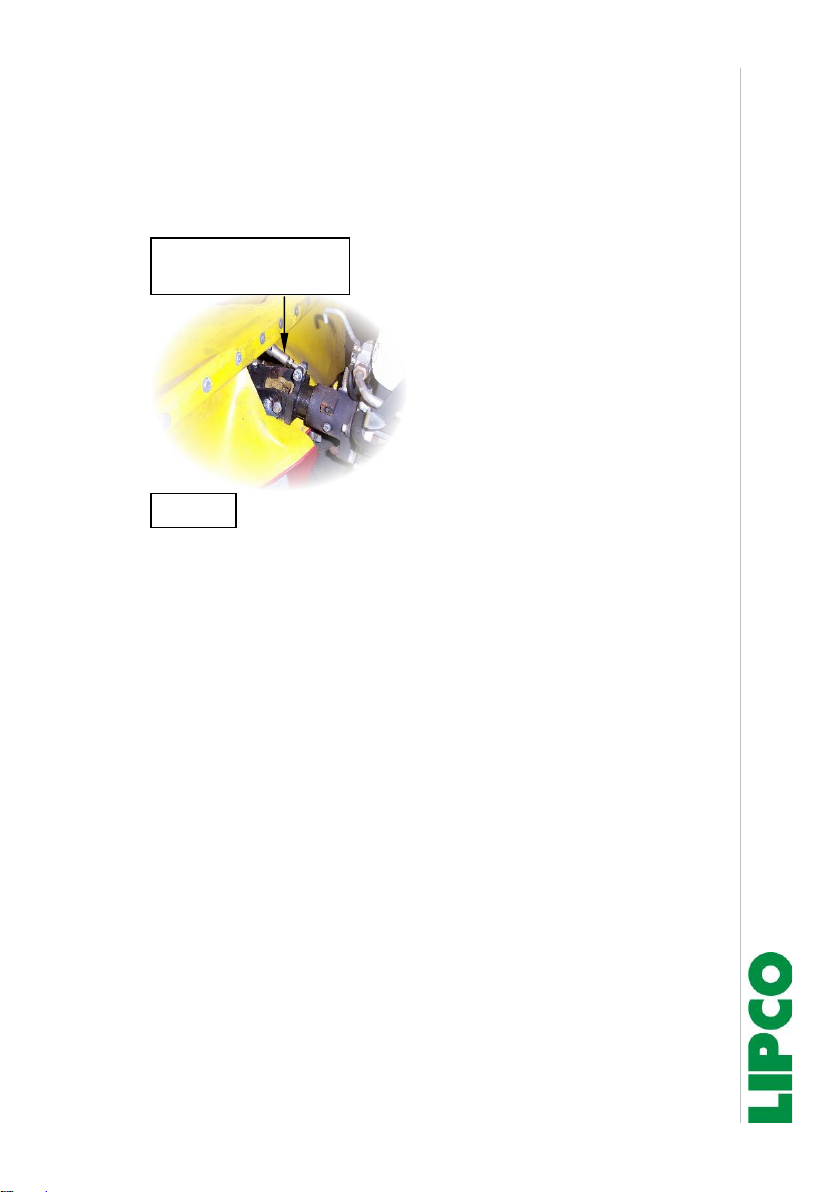

7. Connection to the engine-driven machine

Before attaching the machine flange (Fig. 1, Ref. A) corresponding to

the type of engine-driven machine you have, it is recommended to

spread grease on the outer diameter of the machine hub (Fig. 1, Ref.

B). Then insert the flange with its two threaded pins (Fig. 1, Ref. C)

and the lock nuts. To attach the flange to the hub, proceed as follows:

•Screw the threaded pins in as far as possible and then unscrew

them by one turn. Tighten the lock nuts. After this operation, make

sure that the flange oscillates freely without squeezing or blocking.

•After having greased the connecting shaft (Fig. 1, Ref. D), insert it

on the machine shaft of the Compact Disc Mower. When these

steps are complete, move the engine-driven machine close to the

unit. Ensure the toothed wheel work of the connecting shaft

engages correctly with the power takeoff shaft of the engine-

driven machine and the flange has a centered contact with the

engine-driven machine. Then secure the connection between the

engine-driven machine and the unit.

•Before commencing work, the drive flange must be lubricated.

(Fig. 1, Ref. E)

Fig. 1

B

E

Instructions

Compact disc mower KSM 130

11 - 22

140050-01-EN BA KSM 130 / 04.06.2020

•An optimum mowing result can only be obtained by exact

adjustment of the cutter system inclination. The cutter system

should be inclined forward in the driving direction. This is

accomplished by adjusting the cutter system via the threaded

spindle (Fig. 2).

Spindle for inclination

adjustment

Fig. 2

Instructions

Compact disc mower KSM 130

12 - 22

140050-01-EN BA KSM 130 / 04.06.2020

8. Technical Data

Type

Weight

(kg)

Required

power (kW / hp)

Number of discs/blades

(pcs.)

KSM 130

125

10 / 14

3 / 6

Main dimensions

L1

L2

B

H

KSM 130

750

290

1850

445

Instructions

Compact disc mower KSM 130

13 - 22

140050-01-EN BA KSM 130 / 04.06.2020

9. Operation of the cutter bar / prior to mowing

•Regularly check blades and blade holders for perfect condition

and correct mounting right/left.

(Refer to chapter “11. Maintenance”).

•Never mow without having attached all protective devices.

Protective devices are subject to wear and must be replaced in

good time.

10. Operation of the cutter bar / after mowing

•Clean cutter bar to remove soil and remaining grass. Check all

blades and blade holders with respect to their condition.

Immediately change damaged parts. Do not spray the bearing

areas directly with high-pressure cleaner. Maintenance

instructions (refer to chapter 11.

Instructions

Compact disc mower KSM 130

14 - 22

140050-01-EN BA KSM 130 / 04.06.2020

11. Maintenance

Replacement of the blades

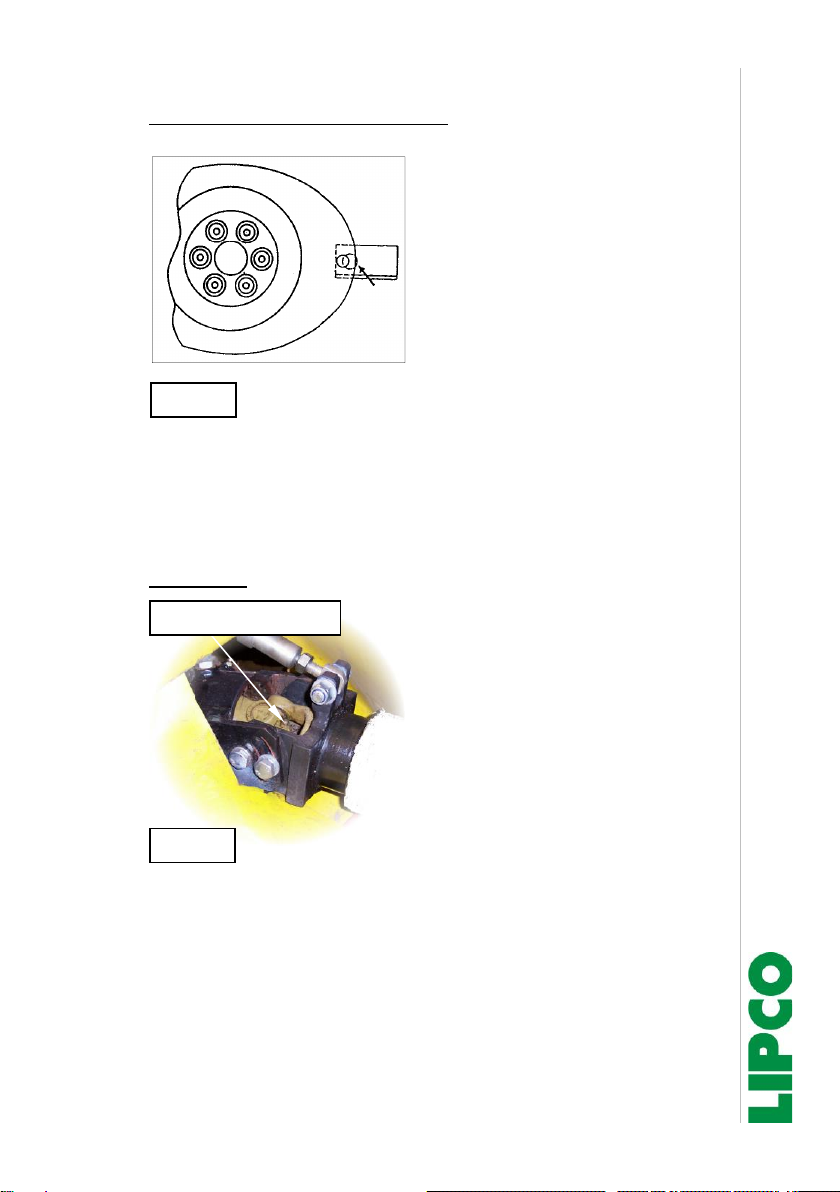

•Insert mounting key (1) between cutting disc (2) and blade holder

(3), press downward and replace blades (4).

(Fig. 3)

•If a cutting edge has become worn out, the blade is only rotated

and used again at the same place. Prior to each use for mowing

and upon rotating them, the blades must be checked for damage

by foreign matter (e.g. rocks). Damaged blades must be replaced

immediately (risk of breaking!).

•For reasons of safety, use original spare parts only. When

replacing the blades, always replace both blades of each cutting

disc (risk of imbalance!).

Fig. 3

Driving

direction

Instructions

Compact disc mower KSM 130

15 - 22

140050-01-EN BA KSM 130 / 04.06.2020

Replacement of the blade holders

•The continuous movement of

the blade will cause the bolt to

become worn. If the hole of a

new blade reaches to the edge

of the cutting disc and is visible

from above, the blade holder

must be replaced immediately.

In this case, the bolt diameter

is worn out to about 30%. To

replace the blade holders, the

disc must be unscrewed.

(Fig. 4)

Before each use for mowing and after each replacement of the

blades, the blade holders must be checked for wear.

•For reasons of safety, use LIPCO original spare parts only.

Lubrication

•The cardan joint must be

lubricated via the lubricating

nipples especially provided for

this purpose (Fig. 5).

•Drive flange: Lubricate once a month and turn it –must run

smoothly when turning. (see Fig. 1 - E)

•Remove drive flange once a year, clean it to remove dirt and

regrease it.

Fig. 4

Fig. 5

Lubricating nipple

Instructions

Compact disc mower KSM 130

16 - 22

140050-01-EN BA KSM 130 / 04.06.2020

12. Oil change

•Change the oil in the cutting bar and angular gear after the first 50

operating hours and then every 200 operating hours, but at least

once a year. Change oil while warm but not while hot (risk of

burning!). Use high-grade mineral gear oil SAE 80 or 90.

•The oil level must be checked every 20 operating hours.

•The oil temperature can be 80 –100°C in the angular gear and 40

–50°C in the cutter bar without causing any damage.

Caution! There is a risk of burning if the angular gear is

touched!

•In case of longer downtimes, we recommend depositing the

cutting unit with the cutter bar horizontally in working position, to

allow the cogwheels to become wetted by the oil.

Oil in the cutter bar:

•The oil charging screw (A) for the cutter bar is located between

the middle cutter discs.

•Perform oil level check with the cutter bar in exactly horizontal

position.

•The oil level, as measured in the oil charging hole, should be 12

mm.

•The drain screw (B) is located at the lower end of the cutter bar

under the first cutter disc.

Fig. 6

A

B

Instructions

Compact disc mower KSM 130

17 - 22

140050-01-EN BA KSM 130 / 04.06.2020

•For the cutter bar, high-grade mineral gear oil SAE 80 or 90 must

be used.

Filling amount:

Oil in the angular gear:

•Check the oil level in the angular gear. This is done by tilting the

unit by 90 degrees, so that the bore for the oil charging screw of

the angular gear points upwards.

Oil filling level of angular gear: 2 -3 cm

Attention: Support the machine sufficiently against tilting.

•First oil change after 30–50 operating hours and then every 200

operating hours, but at least once a year. Use gear oil SAE 90.

Filling amount: 0.3 L

•However, it is extremely important to observe the above-

mentioned oil change intervals!

•The used oil must be disposed of in accordance with current legal

regulations.

13. Cutting operation faults

Striations, Marcelling

•Resharpen blades or use new ones. Ensure correct mounting with

respect to clockwise/counterclockwise rotation.

•Set cutter bar inclination!

•When doing so, observe the safety regulations in chapter 5. When

replacing the blades, follow the instruction given in chapter “11.

Maintenance”.

Instructions

Compact disc mower KSM 130

18 - 22

140050-01-EN BA KSM 130 / 04.06.2020

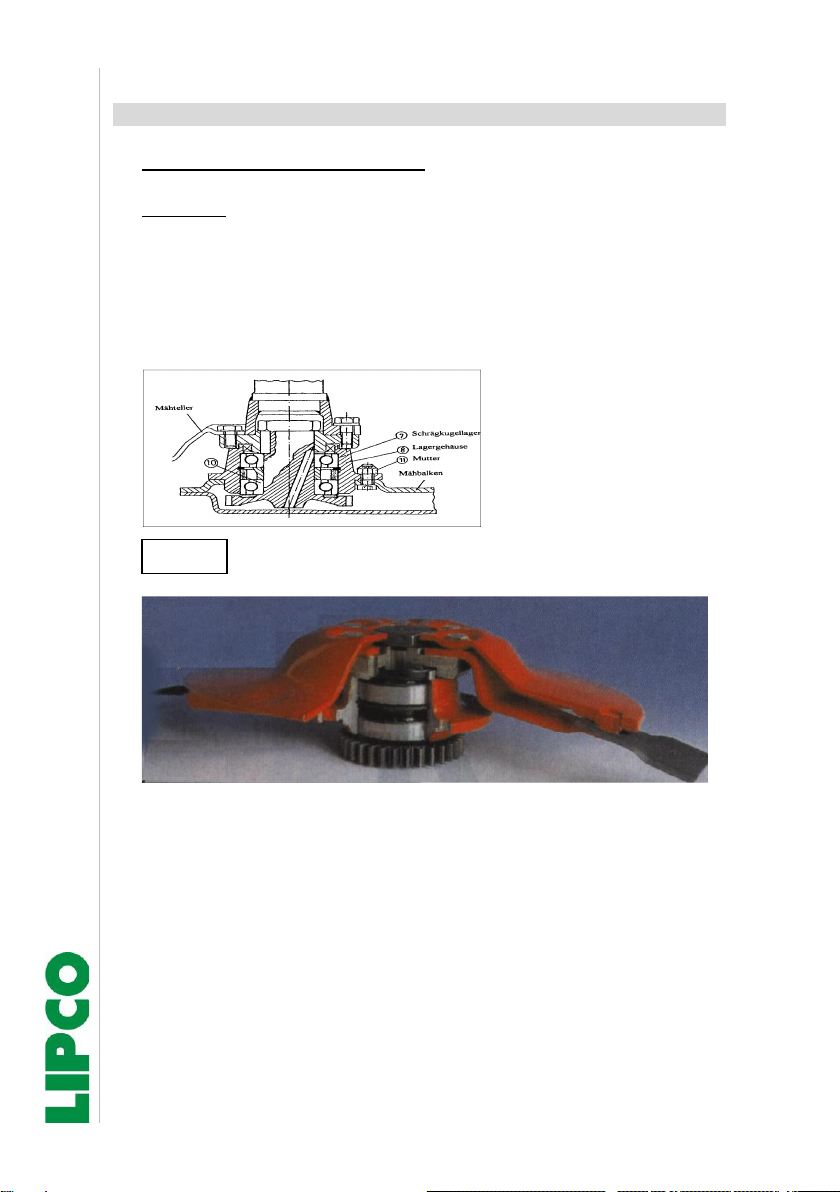

14. Instructions for repair shops

Repair of the cutter disc bearing

Attention!

Here, too, it is imperative to use original spare parts only (owing to

special tolerance).

After removing the cutter discs, the bearing housing (8) can be

removed from the cutter bar toward the top by unscrewing the nut

(11). No further dismounting of the cutter bar necessary.

Angular ball bearing:

The drive cutter disc located directly under the angular gear is

housed on 2 angular ball bearings (7). (For all other cutter discs,

deep groove ball bearings must be used.) The angular ball bearing

must be mounted in the bearing housing (8) such that the bearing

inner rings face each other with their smaller side (10).

Fig. 7

Instructions

Compact disc mower KSM 130

19 - 22

140050-01-EN BA KSM 130 / 04.06.2020

Attention! Removing the angular ball bearings will destroy them and

make it necessary to replace them in any case!

Do not forget the spacer rings between the bearings!

Replacement of the idle wheel and the ball bearings inside the

cutter bar

This is done by unscrewing all screws to remove tray and lid. Only

the cutter disc and the bearings do not have to be unscrewed. Then

push the idle wheels along with the ball bearing away by using two

tire levers. The ball bearing is held in the cogwheel by means of a

retaining ring. The ball bearing can be pressed out of the cogwheel

by applying a pressing force of 5 tonnes. This will only destroy the

retaining ring.

15. After use

If the LIPCO Compact disc mower is to remain unused for a longer

period, it is necessary to carry out the following steps:

•Thoroughly wash and dry the LIPCO Compact disc mower!

•Check the function of all movable parts. Replace damaged or

worn parts!

•Check the tightening of the screws!

•Lubricate free wheel and universal joint shaft!

•Check oil in the angular gear and in the cutter bar!

•Grease all unpainted metal parts to protect them against

corrosion, cover the LIPCO Compact disc mower and store it in a

dry place so that it will be ready for use any time!

•Attention!

When putting the device back into operation, please follow the

instructions in chapter “11. Maintenance”.

Table of contents

Other Lipco Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Maschio

Maschio JUMBO RAPIDO Series Use and maintenance

TMG

TMG TMG-SLP72 product manual

FPM Agromehanika

FPM Agromehanika 627 152 ASSEMBLY / OPERATION/ MAINTENANCE, SPARE PARTS LIST

Kverneland

Kverneland ACPND 65929 Series Technical & service manual

LELY

LELY HIBISCUS 1525 Master Operator's manual

Kemper

Kemper 445 Operator's manual

Poettinger

Poettinger ALPINTOP 300 U Operator's manual

Arrowquip

Arrowquip PORTABLE Q-CATCH 74 Series product manual

Mesko-Rol

Mesko-Rol Z 548 Service manual, Spare Parts

Gaspardo

Gaspardo Primo E2 Use and maintenance

waratah

waratah HTH622B SIII Operator's manual

CrustBuster

CrustBuster Speed King owner's manual