Timan Comfortably better CS 200 User manual

www.timan.dk

CS 200

User Manual

Comfortably better

Applicable to CS 200 types numbers:

User Manual

User Manual

725131-00 725133-00 725135-00

725132-00 725134-00 725136-00

725138-00 725140-00 725142-00

INTRODUCTION

1

1INTRODUCTION ....................................................................................................................... 3

1.1IMPORTANT ........................................................................................................................... 3

1.2IMPROPER USE ....................................................................................................................... 3

1.3IDENTIFICATION OF THE MACHINE ......................................................................................... 4

1.4ORDERING SPARE PARTS: ................................................................................................... 5

2SAFETY RULES ......................................................................................................................... 6

3MAINTENANCE AND ADJUSTMENT SAFETY RULES ...................................................... 7

4MACHINE SPECIFICATIONS .................................................................................................. 8

4.1TECHNICAL DATA. ................................................................................................................. 8

4.2EU DECLARATION OF CONFORMITY ...................................................................................... 9

5EXPLANATION OF WARNING SIGNS ON THE MACHINE ............................................. 10

6THE MACHINE’S CONSTRUCTION ..................................................................................... 11

7CONNECTING AND DISCONNECTING THE MACHINE .................................................. 13

7.1TIMAN TOOL CARRIER ......................................................................................................... 13

7.2TRACTOR ............................................................................................................................ 14

8ADJUSTING THE MACHINE (ROLLER SPREADER)......................................................... 15

8.1MATERIAL (SPLIT/GRAVEL) ................................................................................................ 15

8.2ADJUSTING THE BRACKET FOR THE BOTTOM TRAY .............................................................. 1 6

8.3SPEED OF AGITATOR/DISC SPREADER .................................................................................. 17

8.4SETTING DOSES ................................................................................................................... 18

9ADJUSTING THE MACHINE (DISCSPREADER) ................................................................ 19

9.1HEIGHT OF SPREADER ......................................................................................................... 19

9.2SETTING THE SPREADING WIDTH ......................................................................................... 19

9.3ADJUSTING SPREADING VANES ............................................................................................ 20

9.4SETTING THE APPLICATION POINT ....................................................................................... 21

9.5SETTINGS TABLE ................................................................................................................. 22

10MACHINE LOADS ................................................................................................................... 23

10.1TIMAN TOOL CARRIER ......................................................................................................... 23

11DRIVING BY MACHINE......................................................................................................... 24

11.1COMMISSIONING ................................................................................................................. 24

11.2SWITCH BETWEEN DISC SPREADING AND ROLLER SPREADING ............................................. 24

11.3RUNNING SPEED .................................................................................................................. 24

12OPERATION OF THE MACHINE .......................................................................................... 25

12.1TIMAN 3330 ........................................................................................................................ 25

12.2TIMAN 3400 ........................................................................................................................ 26

12.3CS-200 CONTROL BOX ........................................................................................................ 27

13ROTATIONAL TEST ............................................................................................................... 28

13.1DOSING MANUAL ................................................................................................................ 28

INTRODUCTION

2

14SERVICE AND MAINTENANCE OF MACHINE ................................................................. 30

14.1LUBRICATION OF THE COMBI SPREADER. ............................................................................ 31

14.2TIGHTENING OF ROLLER DRIVE CHAIN ................................................................................. 32

14.3ADJUSTING THE DOSING PLATE ........................................................................................... 32

14.4ADJUSTING THE HYDRAULIC CYLINDER FOR DISC SPREADER .............................................. 33

14.5QUICK EMPTYING OF CONTAINERS ...................................................................................... 34

14.6REPLACEMENT OF AGITATOR ON ROLLER ............................................................................ 35

14.7POST-SEASON MAINTENANCE. ............................................................................................. 36

15MACHINE WARRANTY TERMS........................................................................................... 37

16USING THE MACHINE - QR CODE ...................................................................................... 39

16.1TIMAN 3400 ........................................................................................................................ 39

16.2TIMAN 3330 ........................................................................................................................ 40

16.3TIMAN 5740 TOOL-TRAC .................................................................................................... 41

16.4TRACTOR/OTHER ................................................................................................................. 42

17HYDRAULICS AND ELECTRICAL DIAGRAMS ................................................................ 43

INTRODUCTION

3

Congratulations on your new TIMAN Combi Spreader CS 200!

These operating instructions will help you to use, adjust and maintain your new machine properly.

Before attempting to drive or operate your new machine, please carefully read these operating

instructions, especially the section on safety rules.

The right and left designations in the operating instructions and on spare part lists are the rear view

of the machine in the direction of travel.

Pictures and illustrations in this manual may be shown or taken by the machine with different types

of equipment, therefore it is not certain that the picture matches 100% with their machine, but for

the shown this does not matter.

1 INTRODUCTION

1.1 Important

CS 200 is a hydraulically driven combi spreader. The service life of the machine depends on how it

is maintained and serviced.

The machine comes with an instruction manual, which must always be available to the operator.

Before attempting to drive or operate the machine, read the operating instructions carefully,

especially the sections concerning the machine’s safety rules (sections 2 and 3).

The machine may only be operated by persons over 16 years of age who are familiar with the

machine's safety rules.

If the operating instructions are damaged or lost, a new one can be ordered from

your local Timan dealer.

If constructive changes are made to the machine, the manufacturer may be released from its liability

and any losses or damages.

The machine is designed to disperse sand, salt and split. Other materials such as seed and fertilizer

can also be spread, but these have not been tested in terms of quantity and spread pattern.

Depending on the equipment, the machine can spread with a total width from 0.8 - 6.0 m.

1.2 Improper use

The machine must not be used unless humans and animals can be kept at minimum distance of 5 m,

as there is a risk that foreign objects may be spit out of the machine.

The machine must not be used to transport people.

INTRODUCTION

4

1.3 Identification of the machine

The machines type plate is located at the front left of the main frame.

The nameplate contains the following information:

Manufacturer: Timan A/S

Fabriksvej 13

6980 Tim, Denmark

Identification number:

Example:

Type: CS200

Year: Year of manufacture

Weight: The spreader’s dead weight/The spreader’s dead weight with disc spreader

Performance: -

Max. load: Maximum permissible load weight (for Timan tool carrier)/Maximum permissible

load weight (other)

7251xx-00-1001

Type Serial number Batch number

7251xx 00 1001

INTRODUCTION

5

1.4 Ordering Spare Parts:

Your dealer will be more than happy to help you to maintain your new machine in such a way that

you can enjoy it as much as possible. Having carefully read these user instructions, you will find out

that part of the service work can be done by you yourself. But if spare parts and larger service are

required, please contact your Timan dealer from whom you purchased the machine or your local

authorized Timan service centre.

To speed up the dispatch and avoid wrong consignments, please give the following information

when you are ordering spare parts:

Machine identification number: ________________________________

Spare part number and the required number of parts

Method of delivery

Find out the identification number and write it above and also on the front page of the catalogue.

SAFETY RULES

6

2 SAFETY RULES

IF THIS SYMBOL IS IN THE MANUAL, YOUR SAFETY IS CONCERNED

The user is responsible for the installation of the protective cover and the overall use of the safety

equipment and for compliance with the safety rules.

Careful driving is the best guarantee for preventing accidents. Before using this machine, please

read carefully this chapter. All drivers - regardless of their level of experience - are obligated to read

this manual before they start using the machine. Training for all drivers in safe driving is the

responsibility of the owner.

The machine can only be used by persons over 16 years who have been familiarized with the

machine and the operating instructions.

Safety rules are intended for your safety - therefore, BE SURE TO:

1. Inform the persons who will work with or in the vicinity of the machine about the safety

rules.

2. Never start the machine before you are clear about your intention.

3. Never start the machine before the installation of all protective covers. Replace or repair

immediately any missing or damaged protections.

4. Ensure that persons who are in the vicinity of the machine keep a minimum distance of 10 m

from the machine in case that the machine is started and working.

5. Stop the tractor and wait until the sweeper stops completely. Before cleaning, lubricating,

adjusting or repairing the machine, remove the key from the tractor ignition lock.

6. Any passengers or another operator must never be present on the machine.

7. No objects that would block its function may be placed in the machine.

8. When working with the machine, never wear loose clothing and keep a safe distance from

rotating parts.

9. Do not touch your hands to working parts of the machine.

10. Before starting driving the machine, it is important to become familiar with the hydraulic

functions and the related movements.

11. Never operate the machine under the influence of alcohol, drugs or similar medicines or when

tired.

MAINTENANCE AND ADJUSTMENT SAFETY RULES

7

3 MAINTENANCE AND ADJUSTMENT SAFETY RULES

1. Before any maintenance or adjustment of the machine, it is necessary to switch off the tractor

engine. Remove the key from the ignition lock (to prevent the engine from starting

unexpectedly).

2. Before carrying out any maintenance or adjustment, make sure that the machine is switched

off completely.

3. Hydraulic equipment:

a. Maintenance and repairs of the machine hydraulic equipment may only be carried out by

persons having knowledge of the hydraulic equipment (including the hazards when

exposed to hydraulic fluid, especially when under pressure).

b. Liability for damage will not apply to damage caused by improper use or improper

maintenance/repair.

c. Before every use, check the hoses for damage (cracks, holes, improper entanglement,

and the like). Replace them immediately if they are damaged.

Note: Never attempt to detect any leak in the hydraulic system manually – hydraulic

fluid under high pressure which escapes from small leaks may not be visible and even a

little drop of oil can cause hand injuries. Use a piece of wood, cardboard, and the like.

4. Always reinstall the protective covers if they have been removed for adjustment or

maintenance. After adjustment, always ensure that all nuts and bolts are properly tightened.

5. Check for the first time after 8 hours of operation. Ensure that all the tools used have been

removed from the machine before reinstalling the protective covers and starting the machine.

6. Before starting the machine, ensure that all persons are out of its reach and at a distance

visible to the operator.

7. Never remove blockages by hand or foot, use a suitable tool instead.

8. It is allowed to use original Timan A/S spare parts only.

MACHINE SPECIFICATIONS

8

4 MACHINE SPECIFICATIONS

4.1 Technical data.

The spreader’s dead weight depends on the type and the equipment installed. The dead weight in

the table below is for a standard machine.

Model CS 200 CS 200

(with disc spreader)

Min. oil flow 20 l/min 20 l/min

Max. effect 6.5 kW 6.5 kW

Hydraulic pressure max. 200 bar 200 bar

Hydraulic connection 1 x pressure/return 1 x pressure/return

1 x bidi

r

ectional

Measurements and weight:

Length 730 mm 730 mm

Width 1075 mm 1075 mm

Height 1010 mm 1010 mm

Capacity 200 l 200 l

Capacity (with limitation plate) * 150 l 150 l

Spreading width 1 m (with spreading plate) ≤ 6 m

Net weight 125 kg 170 kg

Three-point suspension Cat. I Cat. I

* Limiting plate in machine (see section 10)

MACHINE SPECIFICATIONS

9

4.2 EU declaration of conformity

EC Declaration of Conformity

2006/42/EC Annex II A

Manufactu

r

er:

Name Timan a/s

Address Fabriksve

j

13

Post code and cit

y

6980 Tim

Compiler of the technical files (authorized b

y

the manufacturer):

Name Hennin

g

Pederse

n

Address Fabriksve

j

13

Post code and cit

y

6980 Tim

Hereb

y

declares that machine t

y

pe:

‐ Combi spreader CS 200 with type number:

725131-00-xxxx, 725133-00-xxxx, 725135-00-xxxx

725132-00-xxxx, 725134-00-xxxx, 725136-00-xxxx

725138-00-xxxx, 725140-00-xxxx, 725142-00-xxxx

Manufactured in accordance with the followin

g

EU directives:

‐ 2006/42/EC Machiner

y

Directive

and the followin

g

national standards and technical specifications:

‐ ISO 730-1:1994

Si

g

nature: Hennin

g

Pedersen Position: CTO Location Tim Date November 21, 2017

Signature

EXPLANATION OF WARNING SIGNS ON THE MACHINE

10

5 EXPLANATION OF WARNING SIGNS ON THE MACHINE

When developing the machine, every effort was made to ensure operator protection against

safety hazards. However, in special situations the machine can still represent a hazard. Warning

signs are therefore placed on the machine to reduce the risk of damage. It is therefore important

to pay attention to the hazards indicated on the following labels.

Keep the warning signs clean and if damaged, replace them or add the missing signs

immediately.

New labels can be ordered from your local Timan dealer.

a

b

c

d

e

a. WARNING: Read the operating instructions carefully before using the machine.

b. WARNING: Before servicing the machine: Stop the machine and remove the key from the

tractor. Use the operating instructions.

c. WARNING. Risk of crushing hands and feet.

d. WARNING: Safety distance of 5 m to operator, persons and animals. There is a risk of

being hit by fragments.

e. WARNING: Rotating parts. Do not put your hands and feet near the rotating discs.

The machine’s construction

11

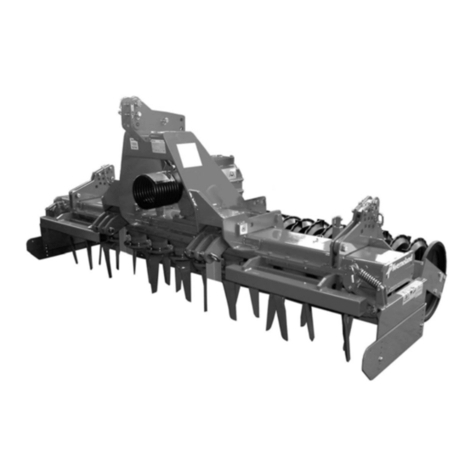

6 The machine’s construction

Front view Rear view

1: Main frame

2: Mounting frame for mounting on Timan tool

carrier

3: Volume control valve for agitator/spreader

speed

4: Change-over valve for tip/cylinder function

5. Side screen

6: Dosing handle for spreading material

7: Diffuser for roller spreadin

g

8: Oil motor for agitator

9: Oil motor for disc spreader

10: Side screen

11: Safety bar

12: Disc spreader

13: Lights

14: Cylinder function for disc spreader

The machine is built around the main frame. In front is a frame for mounting the machine onto

Timan machines or three-point suspension for tractors. The machine’s hydraulic drive is regulated

via the volume control valve which regulates the speed of the roller/and disc spreader (see section 8

and 9 on recommended speeds of roller/and disc diffusers). Change-over valve, for switching

between the tip function and cylinder function on the machine (only applies to machines with a disc

spreader on Timan machines). In the case of tractor models, this function is connected directly from

the tractor's remote socket to the cylinder function on the spreader. When using the cylinder

function, the disc spreader can be moved between spreading position and roller spreading position.

When the disc spreader is in the folded-up position and roller spreading is used, the spreading

screen is tilted under the machine and the material is spread across the full width of the machine.

The disc spreaders are each driven by their oil motors, which are connected in series with the

agitator’s oil motor.

2

3

1

5

7 6

4

9

13

12

10

14

11

8

The machine’s construction

12

On machines without a disc spreader, the spreading plate is mounted on two holes at the front at the

bottom of the main frame, and can be manually tilted from the spreading position to the transport

position.

CONNECTING AND DISCONNECTING THE MACHINE

13

Max. 5 cm

1

2

7 CONNECTING AND DISCONNECTING THE MACHINE

7.1 Timan tool carrier

Before connecting, it is important to check that the machine and the vehicle are on a level and stable

surface.

The connection works as follows, in the following order:

‐ Push the tool lifting truck with the combi spreader to the

vehicle, with an approx. 20 cm. distance.

‐ Fit the hydraulic quick couplings and electrical

connections between the machine and vehicle.

Remember to clean couplings before mounting.

‐ Push the tool lifting truck with the combi spreader

together with the vehicle (with the locking bracket a

max. of 5 cm above the carrier tube) [1] until the

machine is in the correct position on the vehicle.

‐ Lower the tool lifting truck.

‐ Push the locking hooks up so that they can be locked [2].

‐ Lock the two locking hooks on the front frame of the

machine [2].

‐ Start up the machine and check that all functions are

working correctly.

The machine is now ready for use.

The first time the machine is started, the vehicle must be idling, the machine must be empty and the

machine started for approx. 1 min., after which it must be stopped.

The cylinder function of the disc spreader is activated 10 times. This is done to remove any possible

air pockets from the hydraulic system.

The first time the machine is connected, it is important to check that the hydraulic pipes are the

correct lengths so that they are not damaged while using the machine.

Disconnection is done in the opposite order as the connection.

Important: Always disconnect on a level and stable surface.

CONNECTING AND DISCONNECTING THE MACHINE

14

1

2

7.2 Tractor

Before connecting, it is important to check that the machine and the vehicle are on a level and stable

surface.

The connection works as follows, in the following order:

‐ Back the tractor towards the combi spreader.

‐ Mount the lift arms onto the two lift pins [1].

‐ Mount the top link in the top link bracket [2].

‐ Fit the hydraulic quick couplings and electrical connections

between the machine and vehicle.

Remember to clean couplings before mounting.

‐ Start up the machine and check that all functions are

working correctly.

The machine is now ready for use.

The first time the machine is started, the vehicle must be idling, the machine must be empty and the

machine started for approx. 1 min., after which it must be stopped.

The cylinder function of the disc spreader is activated 10 times. This is done to remove any possible

air pockets from the hydraulic system.

The first time the machine is connected, it is important to check that the hydraulic pipes are the

correct lengths so that they are not damaged while using the machine.

Disconnection is done in the opposite order as the connection.

Important: Always disconnect on a level and stable surface.

ADJUSTING THE MACHINE (ROLLER SPREADER)

15

3

4

2

1

8 ADJUSTING THE MACHINE (ROLLER SPREADER)

The procedure for the following adjustments may vary depending on the equipment mounted on the

machine.

8.1 Material (Split/gravel)

IMPORTANT: It is important that the inner sealing plates are removed in the spreader for coarse

material such as split/gravel to protect the machine from unnecessary wear and tear.

When driving with split/gravel in the spreader, it is important that

the internal sealing plates [1] on the right and left sides are

removed from the machine and the three bolts on each side are

reassembled without plates before use.

‐ Remove the two side screens on the right and left sides [2].

‐ Remove the three bolts for the sealing plate on the left side

[3].

‐ Remove the sealing plate inside the spreader.

‐ Refit the three bolts and nuts in the holes on the spreader

[3].

‐ Remove the three bolts for the sealing plate on the right side

[4].

‐ Remove the sealing plate inside the spreader.

‐ Refit the three bolts and nuts in the holes on the spreader

[4].

ADJUSTING THE MACHINE (ROLLER SPREADER)

16

8.2 Adjusting the bracket for the bottom tray

IMPORTANT: It is important that the bracket is lowered for coarse material to avoid unnecessary

wear and tear on the machine.

The rear bracket for the bottom tray under the roller can be adjusted up and down in height

depending on the material being spread. This is to spare the agitators on the roller from coarse

material.

To adjust the bracket up or down, loosen the four nuts on the bracket and it can then be pushed up

or down.

The bracket is pushed up (nut next to the small holes) for fine material, and the bracket is pushed

down (nuts next to the large holes) for coarse material such as gravel and split.

In the table below, the recommended positions for the bracket can be seen in relation to material.

Material Position of brackets Symbol

Dr

y

san

d

On top

Damp san

d

On top

Dr

y

salt On top

Damp salt On top

Split/

g

ravel Bottom

ADJUSTING THE MACHINE (ROLLER SPREADER)

17

2

1

3

8.3 Speed of agitator/disc spreader

IMPORTANT: It is important that the amount of oil/rotation speed is reduced for coarse material

such as split/gravel to protect the agitator from unnecessary wear and tear.

The speed of the agitator/disc spreader is changed by adjusting the volume control valve [1]/[2].

‐ In the case of machines with manual adjustment [1], the hand

screw [3] can be adjusted to the desired speed.

The hand screw is equipped with two stop screws as for min. and

max. revolutions.

‐ For machines with electric control [2] of revolutions, this is

adjusted with the switch [6] for Timan 3330, (see section 12).

The electrically controlled volume divider is adjusted to min.

and max. revolutions.

‐ In the case of machines with electrical control [2] of revolutions,

this is adjusted with the switch [5] on the CS-200 control box for Timan 3400, see section

(12).

The electrically controlled volume divider is adjusted to min.

and max. revolutions.

‐ In the case of machines with electrical control [2] of revolutions,

this is adjusted with the switch [2] for CS-200 control box, see

section (12).

The electrically controlled volume divider is adjusted to min. and

max. revolutions.

The rotation speed is adjusted in the factory to 10 rpm for min. and 35 rpm. for max.

The table below shows guiding values for the revolutions of agitators in relation to the tested

materials.

Material Agitator rotation speed

[rotations per min.]

Dr

y

san

d

10 – 35

Damp san

d

10 – 35

Dr

y

salt 10 – 35

Damp salt 10 – 35

Split/

g

ravel 10 – 20

ADJUSTING THE MACHINE (ROLLER SP

R

EADER)

18

1

2

3

4

8.4 Setting doses

The desired dosage is set with the handle [1]. Move the handle down to open for material and move

the handle up to close for material.

In the case of diffusers with electronic

dosing, this is controlled using the

mounted electric actuator [2].

‐ This is operated using the switch

[5] for Timan 3330 see section

(12)

‐ Or the switch [6] on the CS-200

control box for the Timan 3400

‐ Or the switch [3] for CS-200 control box.

The two stop positions [3] and [4] for the dosing lever can be adjusted as follows, regardless of the

adjustment method:

The lower stop position [4] is adjusted as follows:

‐ For the desired maximum dosage.

‐ When switching between the disc and roller spreader, set it to the dose for the disc spreader.

The upper stop position [3] is adjusted as follows:

‐ For fine/dry material, in the upper position so that the material is closed off when the handle

is up.

‐ In the case of moist material, it can be set to the desired minimum dosage.

‐ When switching between the disc and roller spreader, set it to the dose for the roller

spreader.

This manual suits for next models

9

Table of contents

Other Timan Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Accles & Shelvoke

Accles & Shelvoke CASH Cowpuncher .22R Original instruction manual

WIL-RICH

WIL-RICH PT2200 FWD Operator's manual

Strautmann

Strautmann Verti-Mix 951-1651 Translation of the original operating instructions

Kverneland

Kverneland NGH 301 instruction manual

Irrimec

Irrimec MASTER MT15 Operating and service manual

GrainPro

GrainPro TRANSAFELINER BULK instruction manual