Table of Contents KUNBUS GmbH

ii Gateway Component for PROFINET

Table of Contents

1 General Information ........................................................................................................................3

1.1 Disclaimer..................................................................................................................................3

1.2 Notes Regarding this User Manual............................................................................................3

1.3 Validity .......................................................................................................................................4

1.4 Limitation of Liability ..................................................................................................................4

1.5 Customer Service ......................................................................................................................4

2 Safe Use ...........................................................................................................................................5

2.1 Intended Use .............................................................................................................................5

2.2 User ...........................................................................................................................................5

2.3 Symbols.....................................................................................................................................5

2.4 Important safety instructions......................................................................................................6

2.5 Environmental Conditions..........................................................................................................7

2.6 Data safety ................................................................................................................................7

3 Overview ..........................................................................................................................................8

3.1 Functionality ..............................................................................................................................8

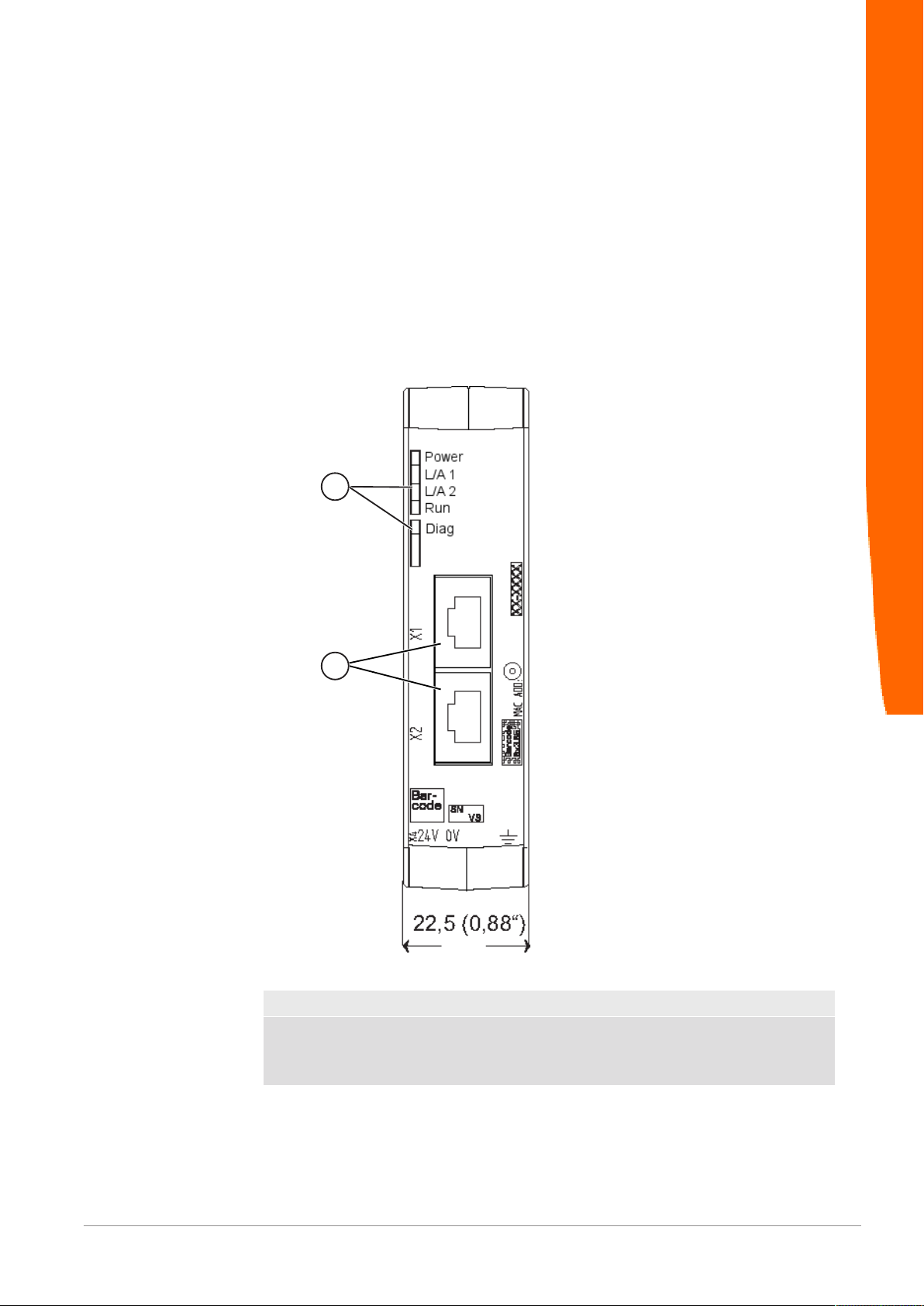

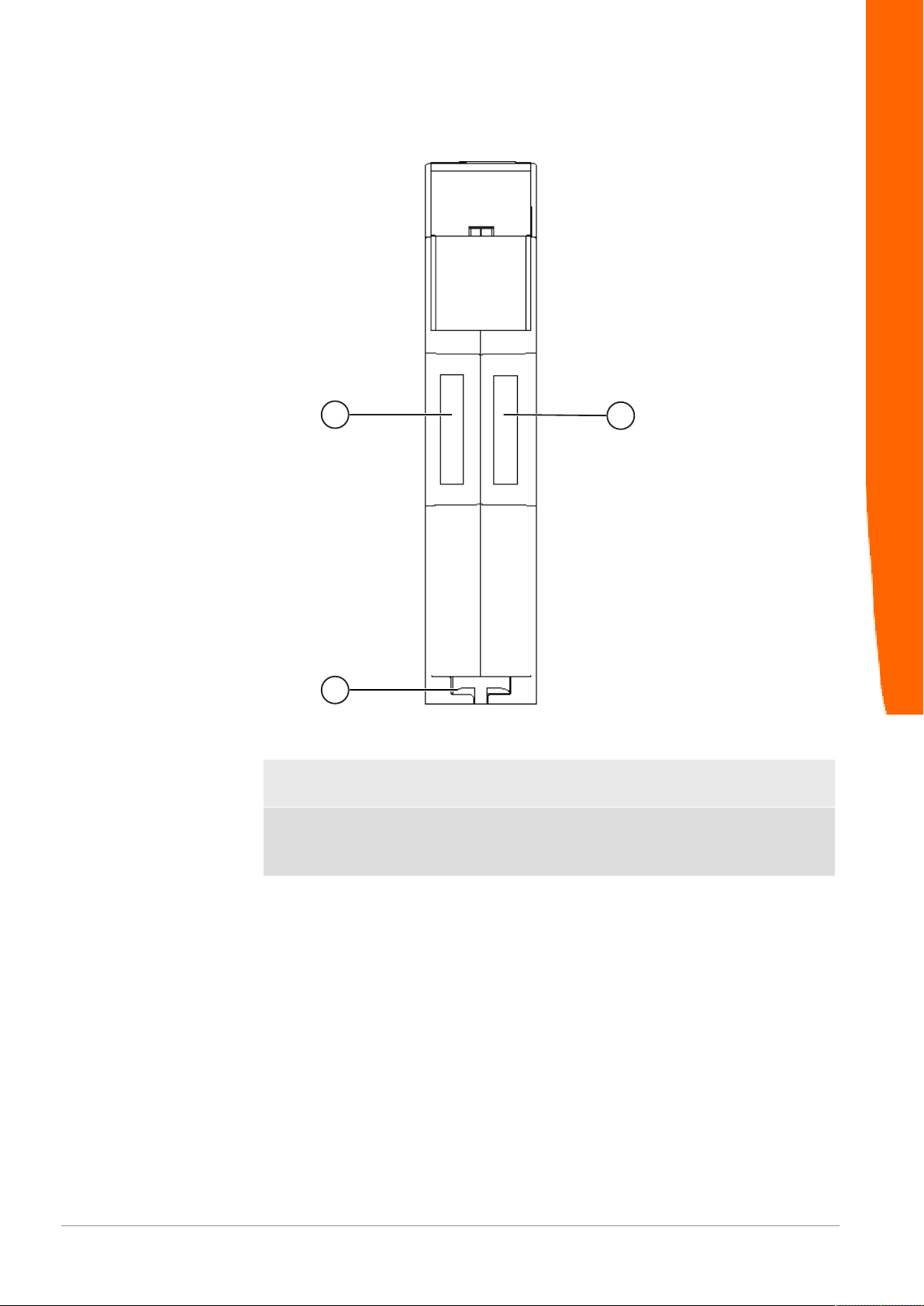

3.2 Control Elements .......................................................................................................................9

3.3 Status LEDs.............................................................................................................................12

4 Installation .....................................................................................................................................13

4.1 Preparations for Inteference-free Operation............................................................................13

4.2 Requirements .........................................................................................................................15

4.3 Connecting Gateway Components..........................................................................................16

4.4 Installing a Gateway in the Control Cabinet ............................................................................17

4.5 Connecting a Power Supply ....................................................................................................18

4.6 Connecting a Gateway to the Fieldbus....................................................................................19

5 Configuration.................................................................................................................................20

5.1 Supported size of process data ...............................................................................................20

5.2 Setting Station Name...............................................................................................................20

5.3 Exchanging Data cyclically ......................................................................................................21

5.4 Exchanging Data acyclically (Records) ...................................................................................25

5.4.1 I&M Data....................................................................................................................... 27

5.4.2 Diagnosis Alarm............................................................................................................ 28

6 Integrated servers .........................................................................................................................29

6.1 FTP-Server ..............................................................................................................................29

6.2 Webserver ...............................................................................................................................29

6.3 Firmware Update .....................................................................................................................31

7 Technical Data...............................................................................................................................42

7.1 Technical Data.........................................................................................................................42