kuongshun eletronics company limited

10.

6Hot bed with four, extruder with 2

24.

Power 220 v input

line 1

25.

12 v power supply

output line 4

4. Installation instructions

Table 7 May need to be in the process of installation tools

Synchronous belt wheel a few

Coupling a few meters installed

One General specification

specification screwdriver

small specification screwdriver

7. Soldering iron 1

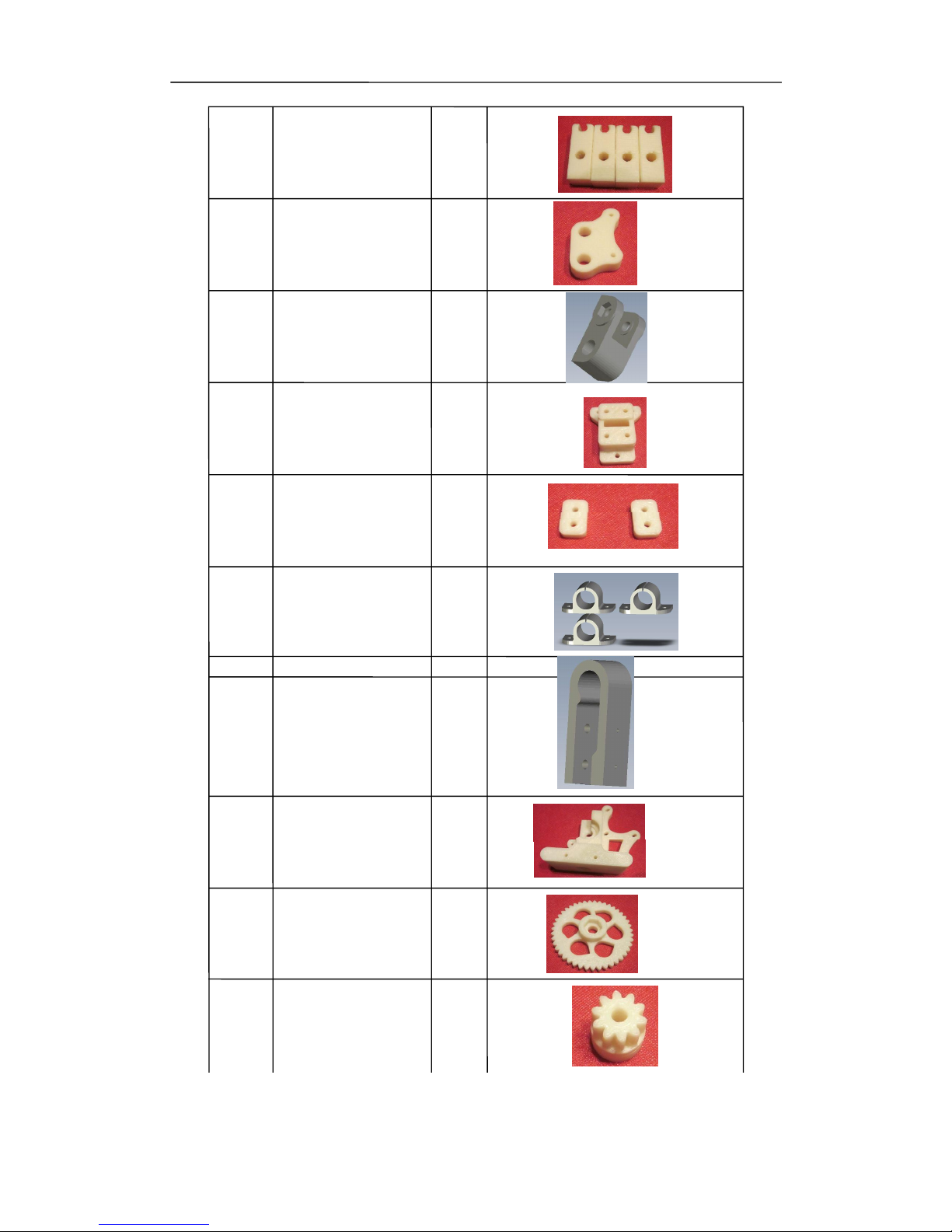

Due to the print not special

accurate,some Holes may be

you may need a hand electric