3H8-93-01

Table of contents

Table of contents

1 Safety precautions........................................................................................................4

1.1 Qualification of the Technical Service Personnel................................................................4

1.2 Personal safety equipment..................................................................................................4

1.3 Danger symbols..................................................................................................................4

1.4 Electrical Safety..................................................................................................................5

1.5 Spare parts..........................................................................................................................5

1.6 Environmental protection....................................................................................................5

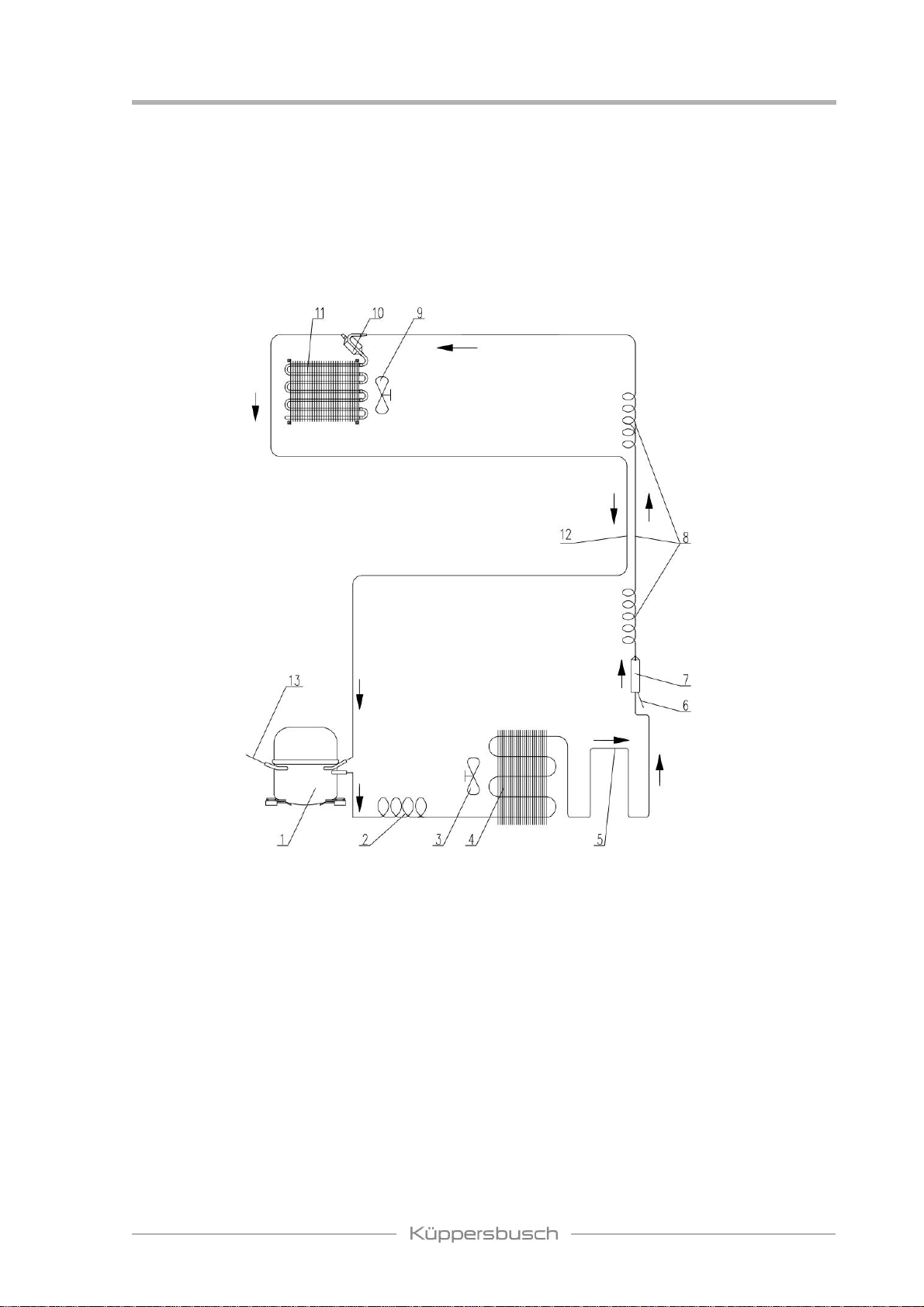

2 Refrigerant and cooling system .................................................................................6

2.1 Refrigerating cycle..............................................................................................................6

2.2 Refrigeration system...........................................................................................................8

3 Electrical and control systems ....................................................................................8

3.1 Control description..............................................................................................................8

3.2 Diagrams...........................................................................................................................13

3.3 Diagram for PCB...............................................................................................................15

3.4 Sensor resistance table.....................................................................................................16

4 Compressor room and parts list...............................................................................17

5 Doors............................................................................................................................18

5.1 Door stop...........................................................................................................................18

5.2 Door alignment..................................................................................................................20

5.3 Changing the door sealing................................................................................................20

5.4 Changing the LED Lamp...................................................................................................21

6 Replacing main parts..................................................................................................22

6.1 Control PCB, fan motor, ventilation flap and LED light in the middle divider ....................22

6.2 Replacing the power PCB.................................................................................................23

6.3 Evaporator fan motor and temperature sensor in the upper part of

dual-zones models............................................................................................................23

6.4 PTC heating, fan motor heating, temperature sensor in the lower part

of the dual-zones models..................................................................................................24

6.5 Evaporator fan motor, Temperature sensor and PTC heating in the

single zone models...........................................................................................................24

6.6 Evaporator fan motor and condenser................................................................................25

6.7 Evaporator group..............................................................................................................26

6.8 Compressor, PTC-starter and overload protector.............................................................26

6.9 Filter dryer.........................................................................................................................27

7 Troubleshooting..........................................................................................................27

7.1 Diagnosis guide.................................................................................................................29

7.2 Symptom diagnosis...........................................................................................................29

7.3 Troubleshooting in the refrigerant system.........................................................................31

7.4 Special detailed diagnosis.................................................................................................32

7.5 FAQ...................................................................................................................................40