3

3 | ENLGISH

Table of Contents

Introduction .................................................................................................................3

Setup Instructions......................................................................................................4

Operating Instructions .........................................................................................5-7

DX6 Parts List ...............................................................................................................8

DX6 Mechanical Drawing........................................................................................9

Maintenance Schedule....................................................................................10-12

Troubleshooting Tips............................................................................................. 13

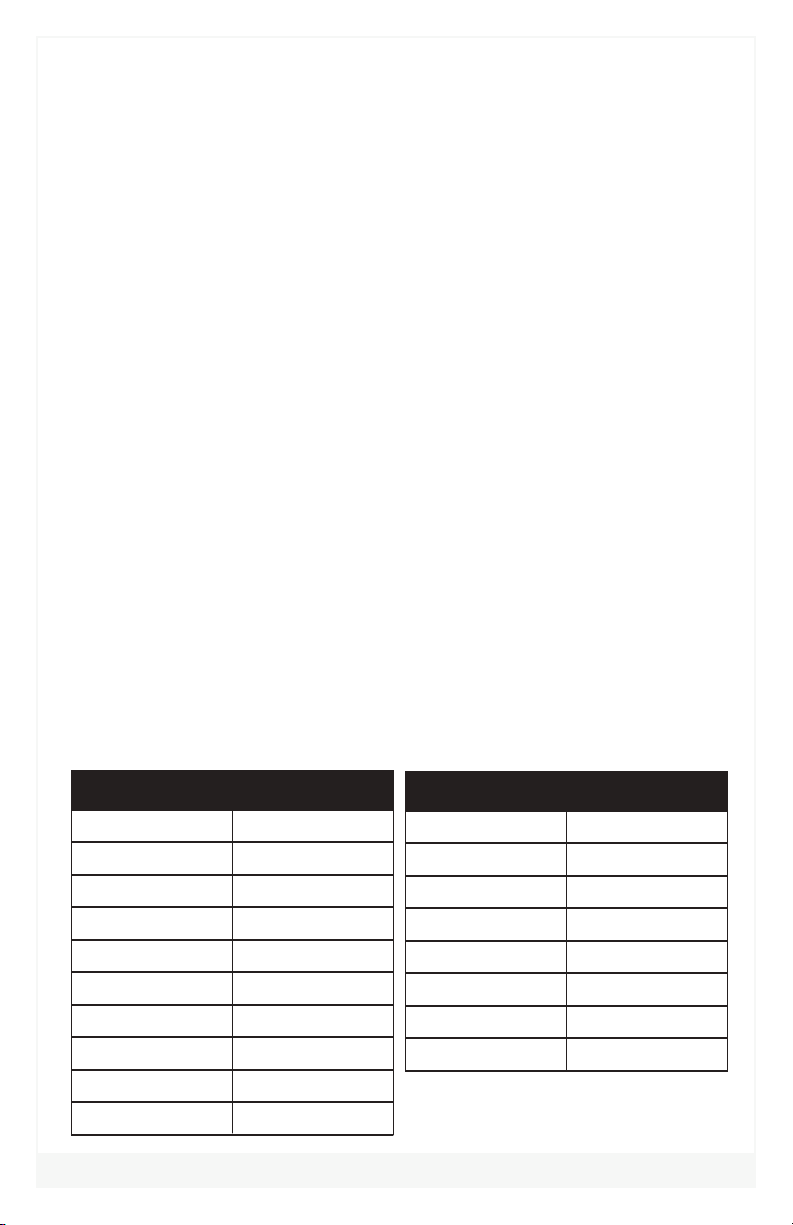

Vise Data

Use this to ll out information about your vise for quick reference.

Purchase Date: _______ -_______- _______

Purchase Order: _______________________

Purchased From: _______________________

Delivery Date: _______________________

Serial No.: _______________________

Note:

Make sure to register your warranty online at kurtworkholding.

Introduction

Thank you for purchasing a Kurt DX6 vise. You have just purchased one

of the best machine vises in the industry. The outstanding accuracy

of this product is second to none. Backed by a lifetime warranty, this

product will last forever when used and maintained properly.

The original Kurt Anglock vises are designed for precision clamping on

basic machine tools such as knee-type mills, grinders and machining

centers. They can be used for, but are not limited to, operations like

precision boring, drilling, tapping, grinding & nishing.

The patented Anglock design allows the movable jaw to advance in

such a way that each pound of force forward induces a ½ pound force

downward which minimizes the jaw lift and increases accuracy. This

combined with the needle bearings increases jaw clamping pressure.

Other features include: 80,000 psi ductile iron body, hardened vise bed

& jaw plates, semi-hard steel screw.

Table of Contents Introduction

INTRODUCTION

Thank you for purchasing a Kurt 3800H. You have just purchased one

of the best machine vises in the industry. The outstanding accuracy of this

product is second to none. Backed by a lifetime warranty against

workmanship and material defects, this product is built to last when used

and maintained properly.

The original Kurt Anglock vises are designed for precision clamping on

basic machine tools such as knee-type mills and machining centers. They

can be used for, but are not limited to, operations like precision boring,

drilling, tapping, & finishing.

The patented Anglock design allows the movable jaw to advance in such a

way that each pound of force forward induces a ½ pound of force

downward which minimizes the jaw lift and increases accuracy. This,

combined with the needle bearings, increases jaw clamping pressure.

Other features include: 80,000 psi ductile iron body, hardened vise bed &

jaw plates, and a semi-hard steel screw.

INTRODUCTION

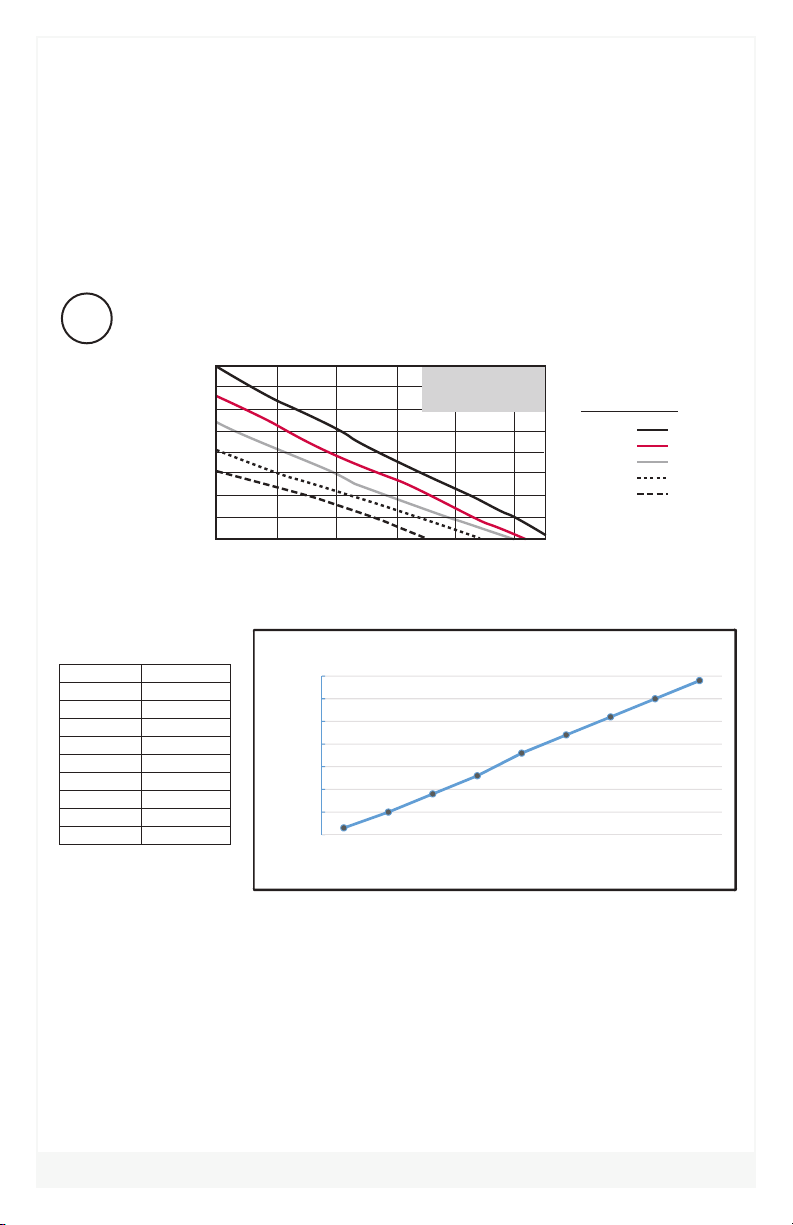

Fig.1