Model350WSB&350WSBWithStandPartsList 5

If you have any questions regarding your warranty rights and responsibilities, you should contact our

CORPORATION Product Support Department for the information.

THINGS YOU SHOULD KNOW ABOUT THE EMISSION CONTROL SYSTEM WARRANTY:

oMAINTENANCEANDREPAIRS

You are responsible for the proper maintenance of the engine. You should keep all receipts and maintenance records

covering the performance of regular maintenance in the event questions arise. These receipts and maintenance

records should be transferred to each subsequent owner of the engine. We reserves the right to deny warranty

coverage if the engine has not been properly maintained. Warranty claims will not be denied, however, solely

because of the lack of required maintenance or failure to keep maintenance records.

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION CONTROL DEVICES AND SYSTEMS MAY

BE PERFORMED BY ANY REPAIR ESTABLISHMENT OR INDIVIDUAL; HOWEVER, WARRANTY REPAIRS

MUST BE PERFORMED BY A SERVICE DEALER AUTHORIZED BY US. THE USE OF PARTS THAT ARE

NOT EQUIVALENT IN PERFORMANCE AND DURABILITY TO AUTHORIZED PARTS MAY IMPAIR THE

EFFECTIVENESS OF THE EMISSION CONTROL SYSTEM AND MAY HAVE A BEARING ON THE

OUTCOME OF A WARRANTY CLAIM.

If other than the parts authorized by us are used for maintenance replacements or for the repair of components

affecting emission control, you should assure yourself that such parts are warranted by their manufacturer to be

equivalent to the parts authorized by us in their performance and durability.

HOW TO MAKE A CLAIM

All repair qualifying under this limited warranty must be performed by a service dealer authorized by us. In the

event that any emission-related part is found to be defective during the warranty period you shall notify our

CORPORATION Product Support Department.

3.

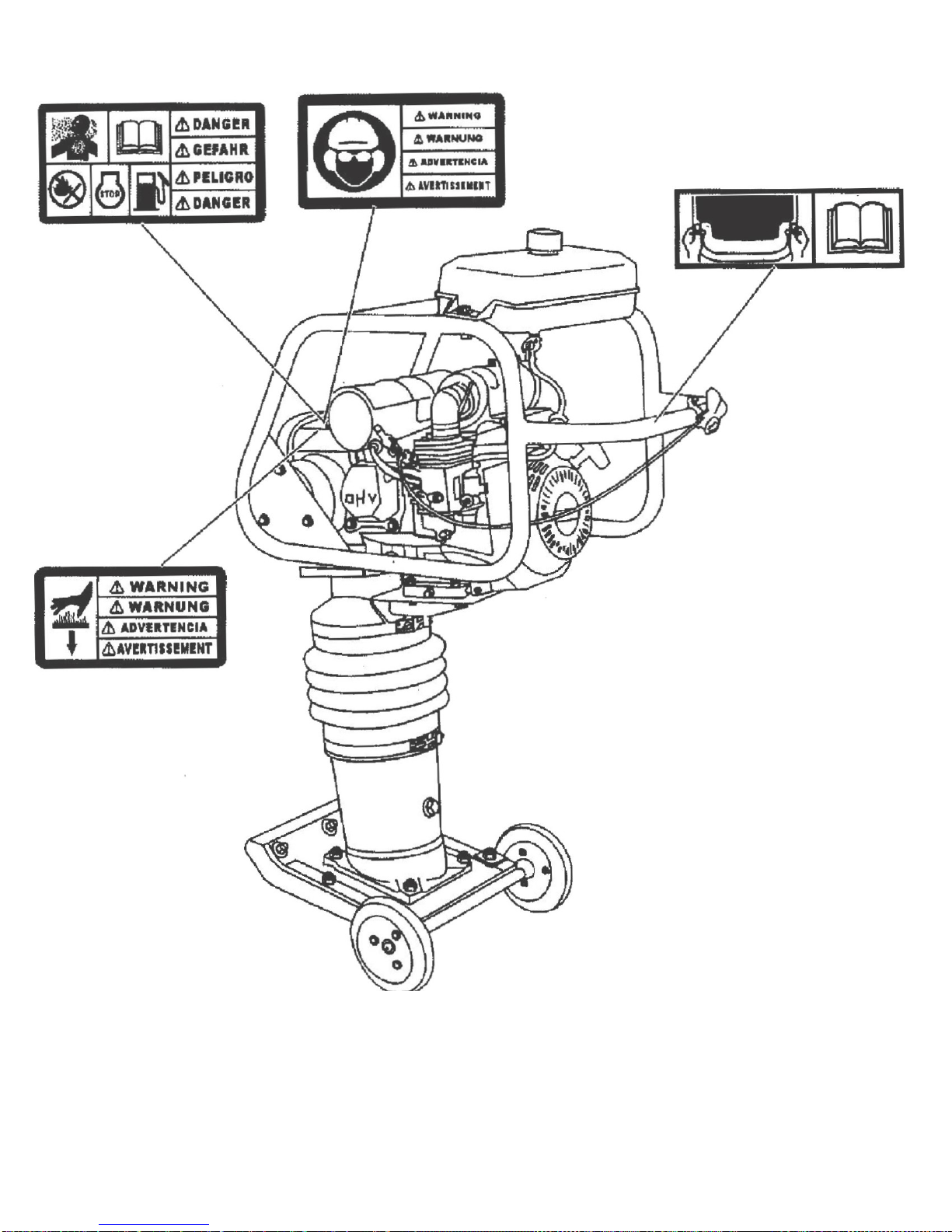

SAFETY INFORMATION

This manual contains DANGER, WARNING, CAUTION, and NOTE callouts which must be followed to reduce the

possibility of personal injury, damage to the equipment, or improper service.

This is the safety alert symbol, It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

DANGER

indicates a hazardous situation which, if not avoided will result in death or serious injury.

WARNING

indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

CAUTION

: Used without the safety alert symbol,

CAUTION

indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

Note:

Contains additional information important to a procedure.

3.1

OperatingSafety

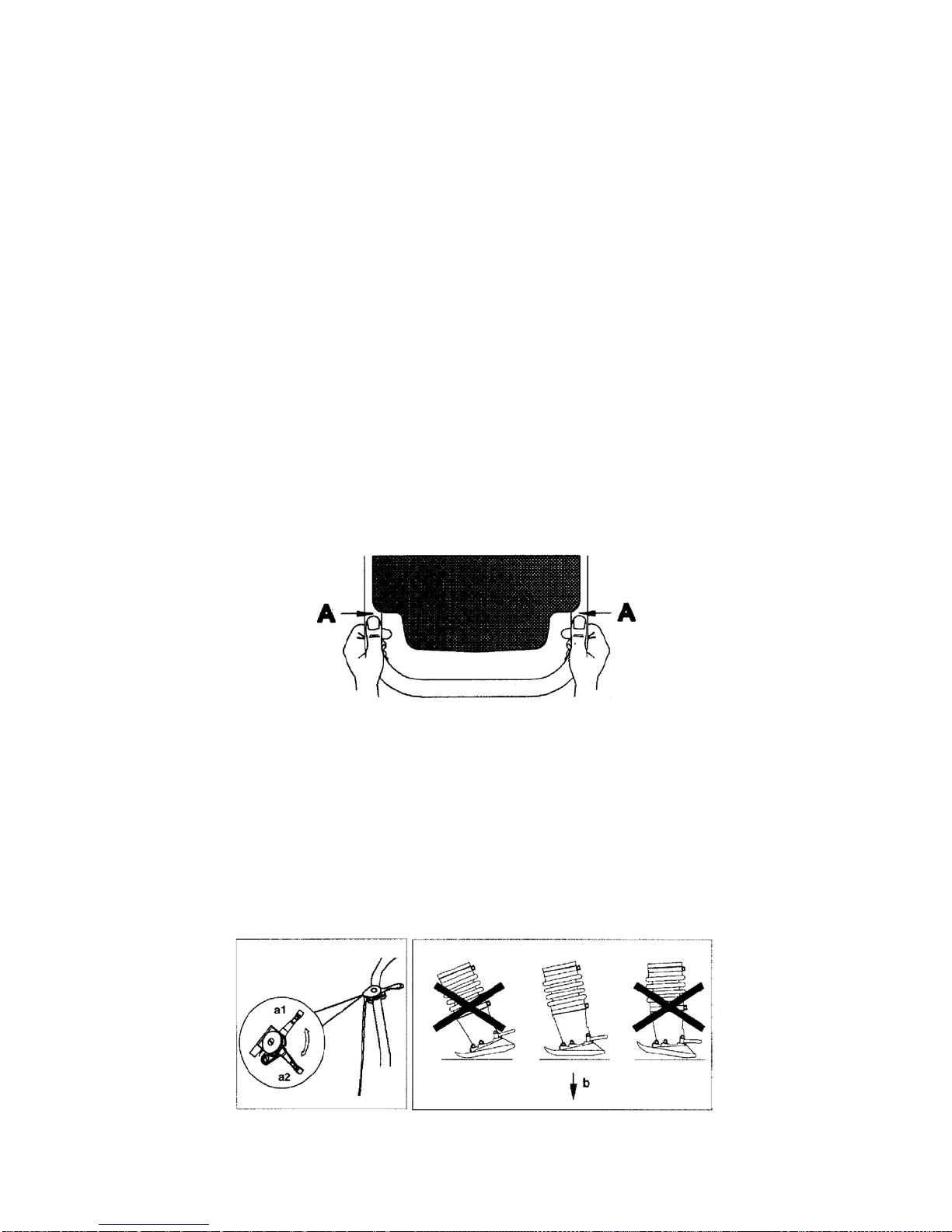

Familiarity and proper training are required for the safe operation of equipment. Equipment operated improperly

or by untrained personnel can be dangerous. Read the operating instructions contained in both this manual and

the engine manual and familiarize yourself with the location and proper use of all controls. Inexperienced operators

should receive instruction from someone familiar with the equipment before being allowed to operate the machine,

3.1.1

NEVER

operate this machine in applications for which it is not intended.

3.1.2

NEVER

allow anyone to operate this equipment without proper training. People operating this equipment

must be familiar with the risks and hazards associated with it.

3.1.3

NEVER

touch the engine or muffler while the engine is on or immediately after it has been turned off. These

areas get hot and may cause burns.

3.1.4

NEVER

use accessories or attachments that are not recommended by us. Damage to equipment and injury to

the user may result.

3.1.5

NEVER

leave machine running unattended.

3.1.6

NEVER

tamper with or disable the function of operating controls.

3.1.7

NEVER

use choke to stop engine.

3.1.8

NEVER

operate the machine in areas where explosions may occur.

3.1.9

ALWAYS

read, understand and follow procedures in the Operator’s Manual before attempting to operate the

equipment.

3.1.10

ALWAYS

be sure that all other persons are at a safe distance from the machine. Stop the machine if people

step into the working area of the machine.

3.1.11

ALWAYS

be sure operator is familiar with proper safety precautions and operation techniques before using

machine.