Polish terminal part of battery

pack with dry cloth, etc

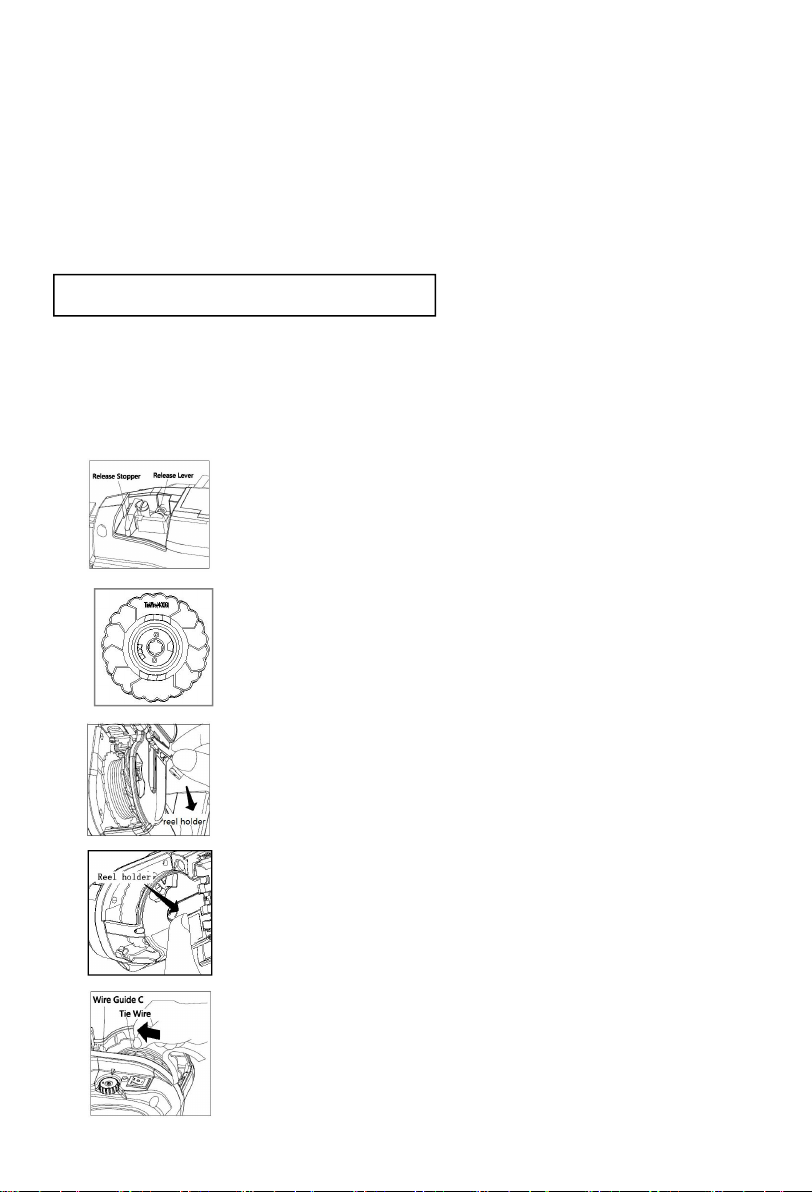

Turn off power, remove binding

wire inside curl guide

Either wipe Cutter section with dry

cloth or blow it with air

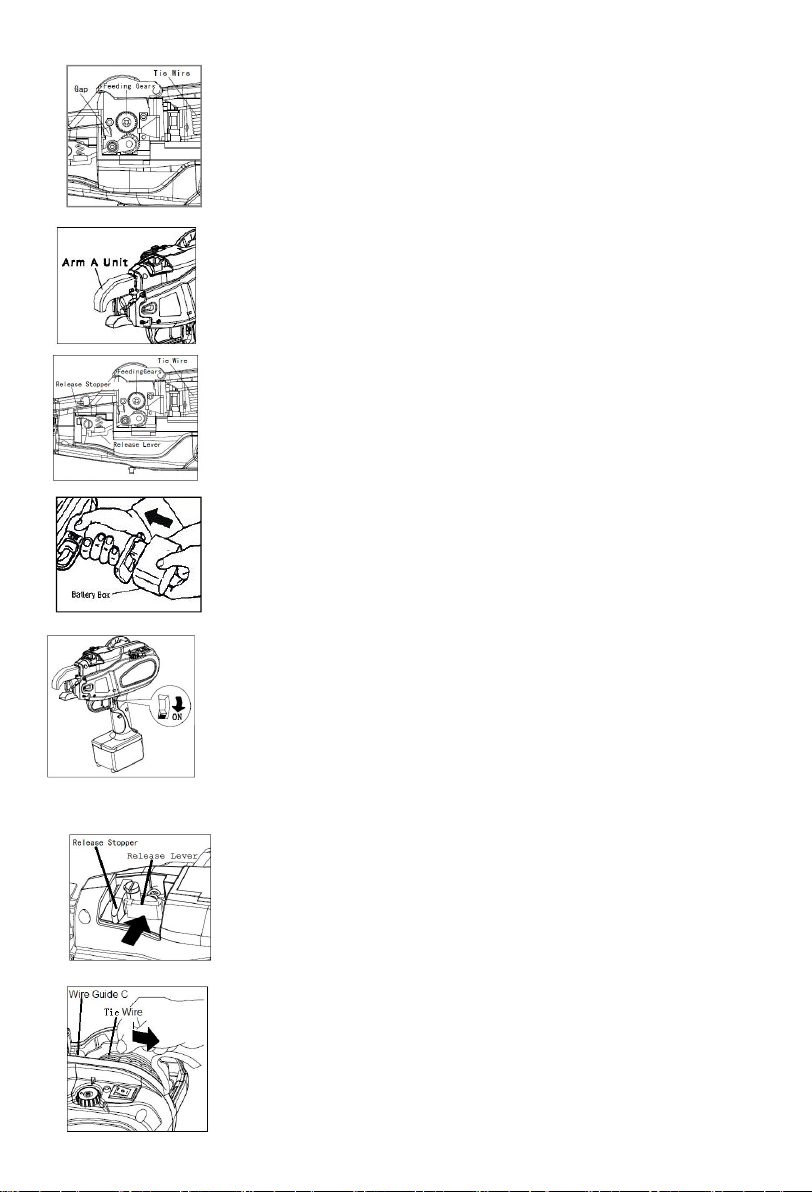

Diassemble the cutter section and

remove the caught wire

Pay attention so that wire does not

hit reinforcing bars at binding

Either wipe Cutter section with dry

cloth or blow it with air

Pay attention so that wire does not hit

reinforcing bars at binding.

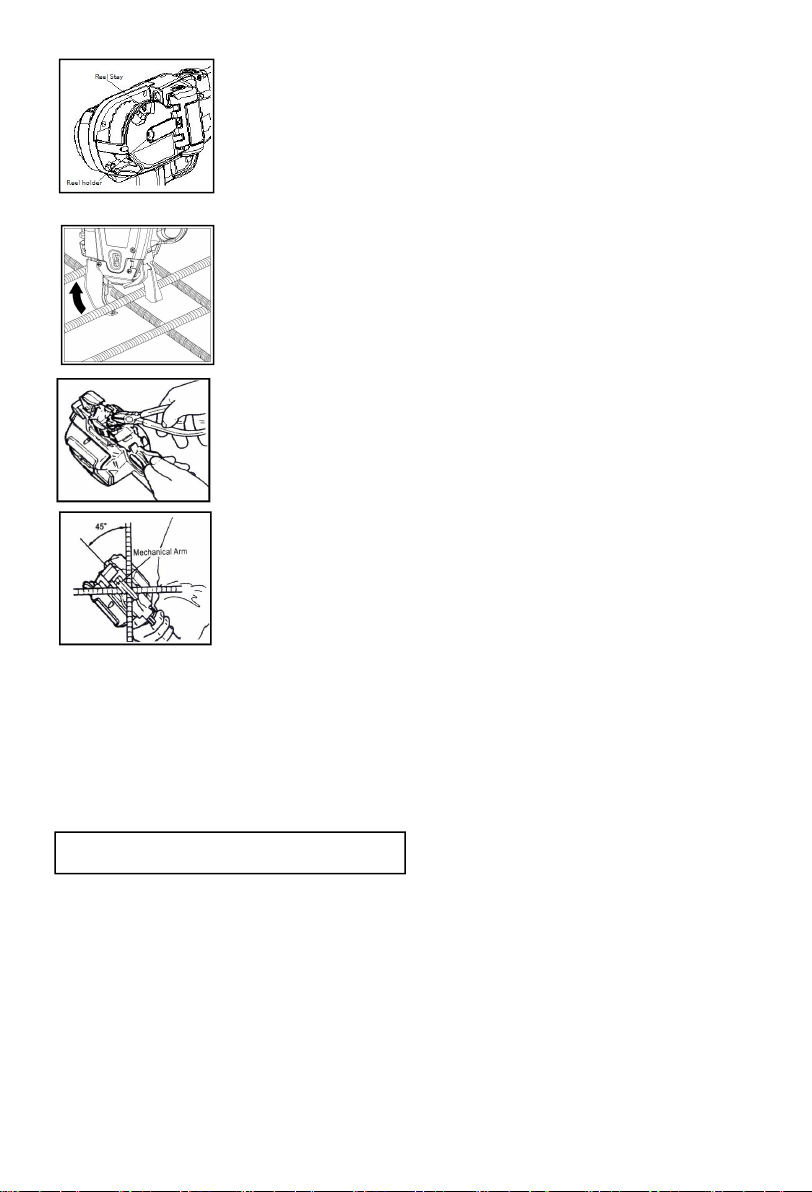

Use approriate diameter scope

Adjust the Torque to a higher lever

and insert in vertical direction. use

as tilting at45°

Use approriate diameter scope

Adjust the Torque to a lower lever

and insert in vertical direction. use

as tilting at45°

Leave the tool and the battery pack

at normal temperature in the room

for some time. and then continue the

operation.

Confirm the battery is charged.

Take out the battery and see if the

electrode has been brown.

Turn off power and take out the

battery to confirm if binding wire has been

entangled inside curl guide.

Confirm the battery is charged

Check if the Tie-wire has been run

Check if wire inside reel has been

loosened and caught

Confirm functioning of Cutter section

Check if any wire is caught.

check if wire hits reinforcing bars at binding

Confirm function of Cutter section.

Check if wire hits reinforcing bars at binding

Confirm size of reinforcing bars to be bound

Confirm how to apply machine to

reinforcing bars

Confirm size of reinforcing bars to be bound

Confirm how to apply machine to reinforcing

bars

Confirm the battery is fully charged.

Check the temperature at the job site.

Electrode plate has been

oxidized

Binding wire has been

entangled around Twist section.

Tie-wire has been run out

Cutter section is blocked with foreign

substance

A wire is caught in the cutter section or

Wire guide A

Wire, by hitting reinforcing

bars, was repelled

Cutter section is blocked with foreign

substance

Wire, by hitting reinforcing

bars,was repelled

Reinforcing bars is not of

designated size.

Erroneous handling such as

improper application of

machine

Reinforcing bars is not of

designated size

Erroneous handling such as improper

application of

machine

Low power remains in the

battery pack

The tool is used at high temperature.

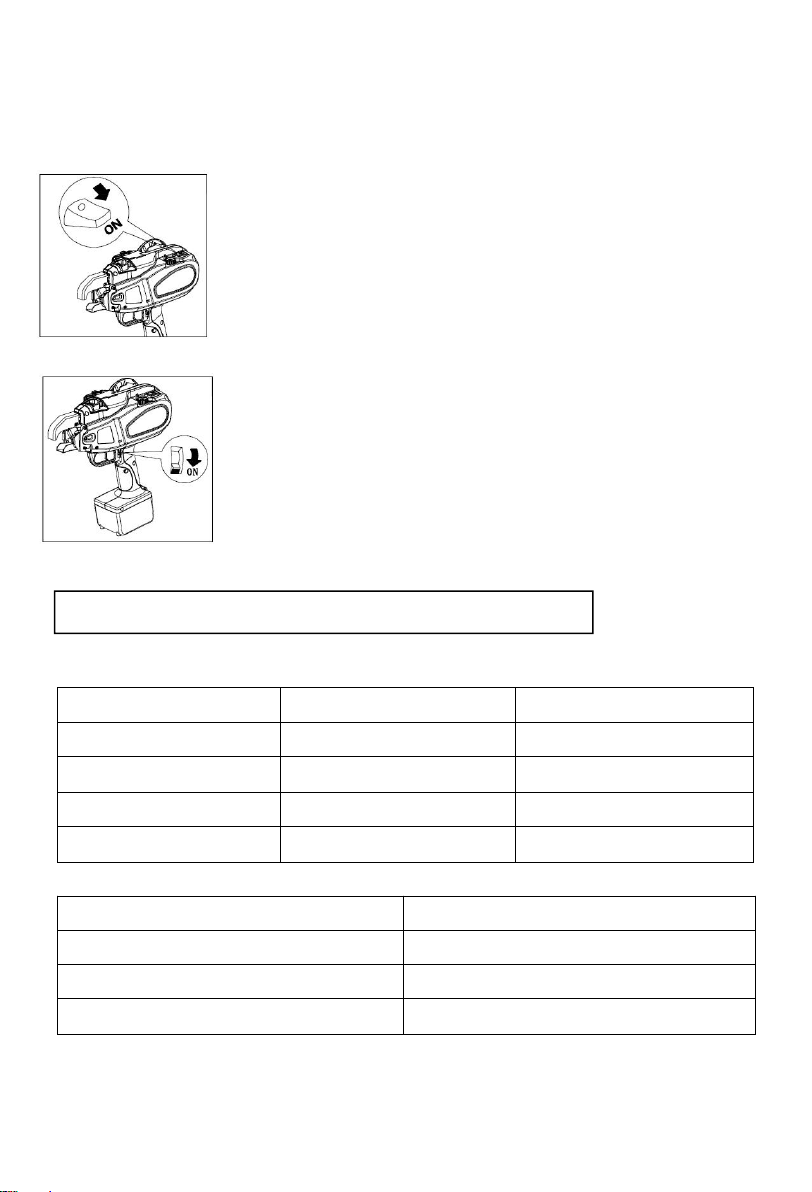

Continuous short

beeps(Pi,pi,pi…)

Three short beeps

repeated(Pi,pi,pi,Pi,pi,pi,

…)

Two long beeps

repeated(Pi-pi, pi-pi,...)

Four short beeps

repeated(Pipipipi,

Pipipipi,…)

Curl is

disordered and

steps out of curl

No wire cutting takes

place.

Power ON→ The Tip

Axis is initialized

and the wire-cutter

operates

automatically.

Trigger ON→

Wire is sent out.

Binding wire

draws a circle.

Wire is subject to

cutting