KYMCO BET & WIN 50 User manual

Other KYMCO Scooter manuals

KYMCO

KYMCO Bet&Win Release note

KYMCO

KYMCO XCITING 500Ri ABS User manual

KYMCO

KYMCO 100 SENTO User manual

KYMCO

KYMCO Mini LS User manual

KYMCO

KYMCO Like 50 User manual

KYMCO

KYMCO People GT 300i User manual

KYMCO

KYMCO SUPER8 50 User manual

KYMCO

KYMCO GRAND DINK 250 User manual

KYMCO

KYMCO 125 AGILITY CITY - Release note

KYMCO

KYMCO ZX/SCOUT 50 User manual

KYMCO

KYMCO 125 SUPER 8 User manual

KYMCO

KYMCO 50 AGILITY RS 4T User manual

KYMCO

KYMCO PEOPLE S 125 User manual

KYMCO

KYMCO 125 DINK - User manual

KYMCO

KYMCO DINK 200 User manual

KYMCO

KYMCO SUPER8 50 User manual

KYMCO

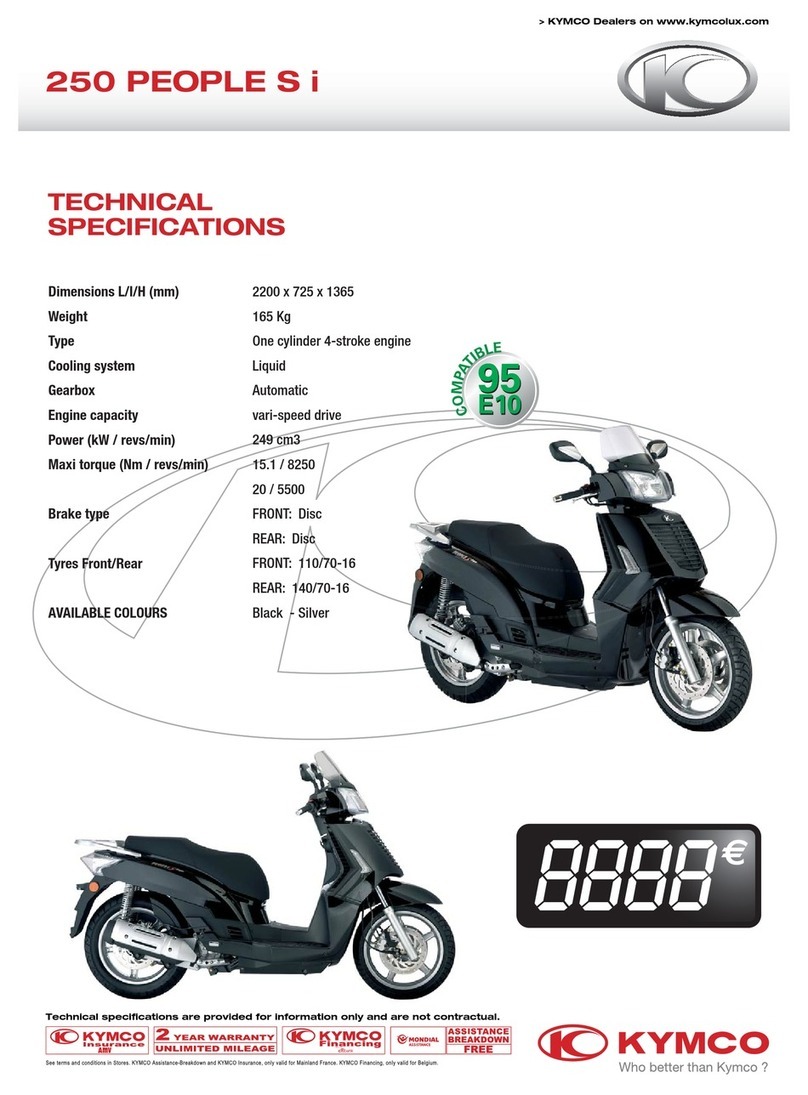

KYMCO 250 PEOPLE S INJECTION User manual

KYMCO

KYMCO SPADE 150i User manual

KYMCO

KYMCO PEOPLE S 50 User manual

KYMCO

KYMCO 125 DINK - User manual