3

NOTE: MAXIMUM SYSTEM VOLTAGE 600VDC.

KD series modules and most PV system com onents have a maximum

system voltage rating of 600 volts DC. Some grid-tie systems o erate

at or near this voltage rating. Like other olycrystalline solar modules,

the o en circuit voltage of the KD series module increases as the

ambient tem erature decreases. Maximum System voltage is

com uted as the sum of the o en-circuit voltage of the

series-connected PV modules for the lowest ex ected ambient

tem erature. Refer to the National Electrical Code Article 690-7(a) for

determining the maximum number of KD series modules that can be

laced

in series. Tem erature coefficients, s ecific to the module of

use, can be used to rovide the most accurate rediction of module

voltage under tem erature extremes.

NOTE: Install the maximum number of series connection for the KD

series PV modules so that the system voltage is less than 600V.

NOTE: In normal conditions, PV modules may roduce bigger current

and/or voltage than re orted in the standard test conditions. Therefore,

when voltage evaluations for com onents, ca acity of conductors, size

of fuses, and size of control systems connected to the module out ut

are determined, multi ly the values of short- circuit current (Isc) and

o en-circuit voltage (Voc) that are marked in KD series modules by the

factor of 1.25. Refer to Section 690-8 of the National Electrical Code for

an additional multi lying factor of 1.25 which may also be a licable.

9. GROUNDING

Before installation, contact the local code authorities to determine the

necessary grounding requirements. Attach all PV module frames to an

earth ground in accordance with the National Electric Code (NEC)

Article 250. Pro er grounding is achieved by connecting PV module

frames and all metallic structural members contiguously to one another

using a suitable grounding conductor. The grounding conductor shall

be of co er, co er alloy or another material suitable for use as an

electrical conductor er NEC. The grounding conductor must then

make a connection to earth using a suitable earth grounding electrode.

Ensure ositive electrical contact through the anodizing on PV module

frame extrusion by utilizing one of the following methods. Attach the

grounding conductor:

(1)to one of the 9mm (0.35”) diameter holes marked “ground” using

5/16” stainless steel hardware. Wra conductor around bolt. Tighten

the screws with adequate torque (usually 132 in-lb). Avoid direct

contact of co er ground conductor to aluminum frame.

(2)to a ground lug (manufacture : ILSCO, model : GBL-4DBT). Tighten

the screws with adequate torque (usually 62 in-lb). Use #10-32

stainless steel hardware to attach the lug to the module frame by the

torque of 40 in-lb. A stainless steel star washer,

ositioned between the lug and the anodized surface of the frame,

must be em loyed to break through the anodized layer of the frame

extrusion and electrically connect the ground lug to the conducting

aluminum frame material.

As a general rule, avoid direct contact of co er or co er alloyed

ground conductors with the aluminum module frame.

All ground bond securing hardware in contact with either the aluminum

module frame and/ or co er or co er alloy ground conductors must

be stainless steel.

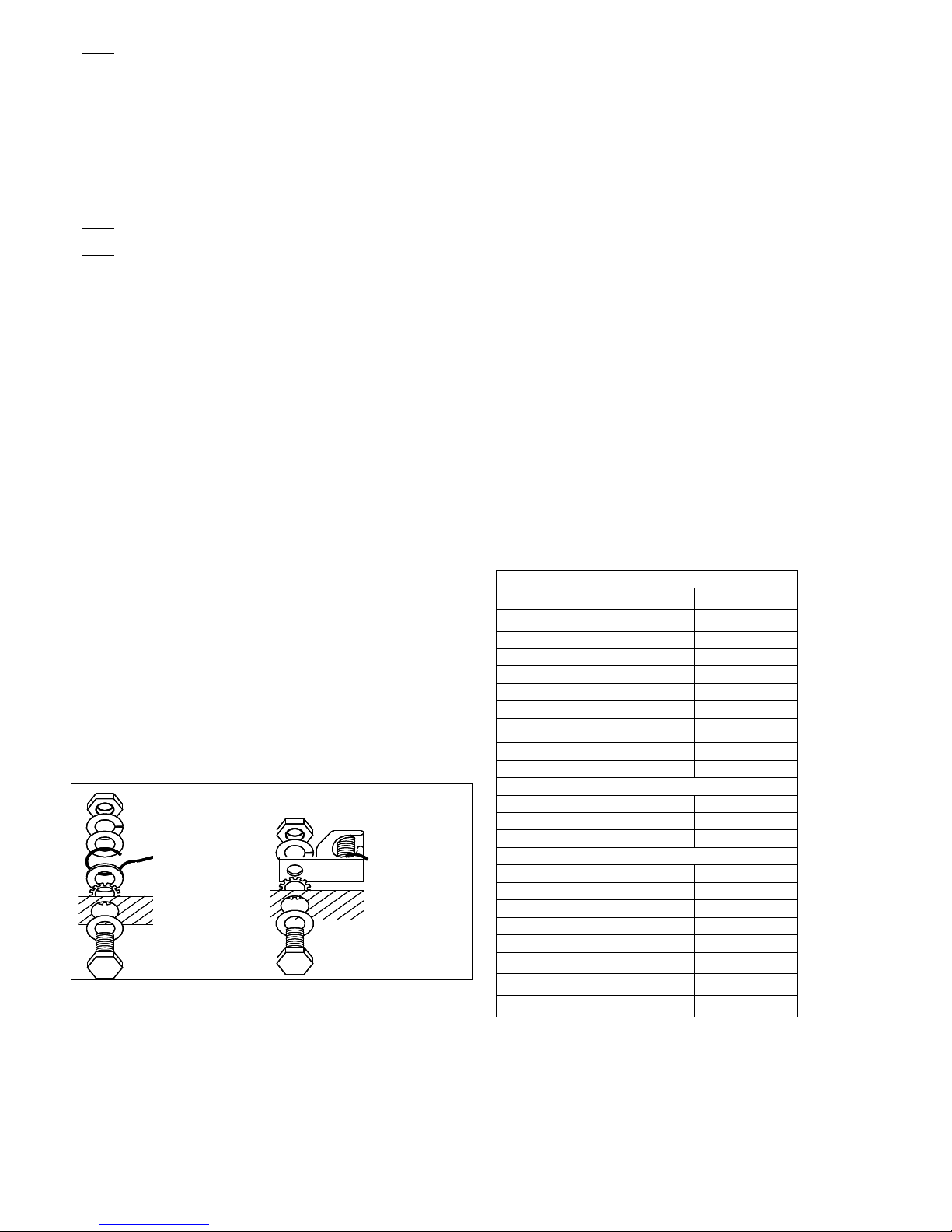

Figure 6. Inst ll tion Ex mple of Grounding

10. BLOCKING DIODES

In systems utilizing a battery, blocking diodes are ty ically laced

between the battery and PV module out ut to revent battery from

discharging at night. Kyocera PV modules are made of olycrystalline

cells with high electrical “back flow” resistance to nighttime battery

discharging. As a result, Kyocera PV modules do not contain a

blocking diode when shi ed from the factory. Most PV charge

regulators and inverter incor orate nighttime disconnect feature,

however.

11. BYPASS DIODES

Partial shading of an individual module in a source circuit string

(i.e. two

or more modules connected in series) can cause a reverse voltage

across the shaded cells within the module. Module out ut current is

then forced through the shaded area by the remaining illuminated cells

and other PV modules in series with the artially shaded module(s).

The current forced through the shaded cells within PV module (or

modules) causes additional module heating and severe loss of ower.

The ur ose of by ass diodes is to rovide a low-resistance current

ath around the shaded cells, thereby minimizing PV module heating

and array current losses.

PV modules em loy by ass diodes that have:

・ Rated Average Forward Current [I

F(AV)

] Above maximum system

current at highest PV module o erating tem erature.

・ Rated Re etitive Peak Reverse Voltage [V

RRM

] Above maximum

system voltage at lowest PV module o erating tem erature.

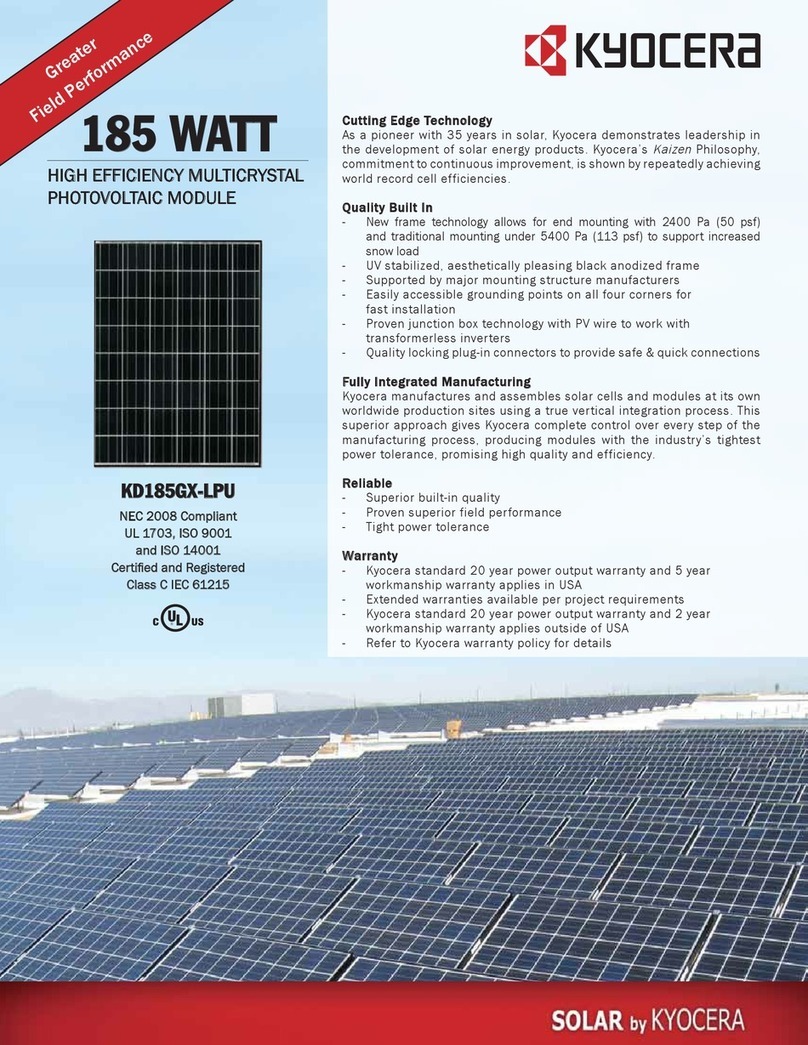

12. MAINTENANCE

Kyocera PV modules are designed for long life and require very little

maintenance. Under most weather conditions, normal rainfall is

sufficient to kee the module glass surface clean. If dirt build-u

becomes excessive, clean the glass surface only with a soft cloth using

mild detergent and water. USE CAUTION WHEN CLEANING THE

BACK SURFACE OF PV MODULE TO AVOID PENETRATING THE

BACK SHEET. PV modules that are mounted flat (0°tilt angle) should

be cleaned more often, as they will not "self clean" as effectively as

modules mounted at a 15°tilt or greater. Once a year, check the

tightness of terminal screws and the general condition of the wiring.

Also, check to be sure that mounting hardware is tight. Loose

connections may result in a damaged PV module or array.

13. SPECIFICATIONS

Under certain conditions, a hotovoltaic module may roduce more

voltage and current than re orted at Standard Test Conditions (STC).

Refer to Section 690 of the National Electrical Code for guidance in

series string sizing and choosing overcurrent rotection.

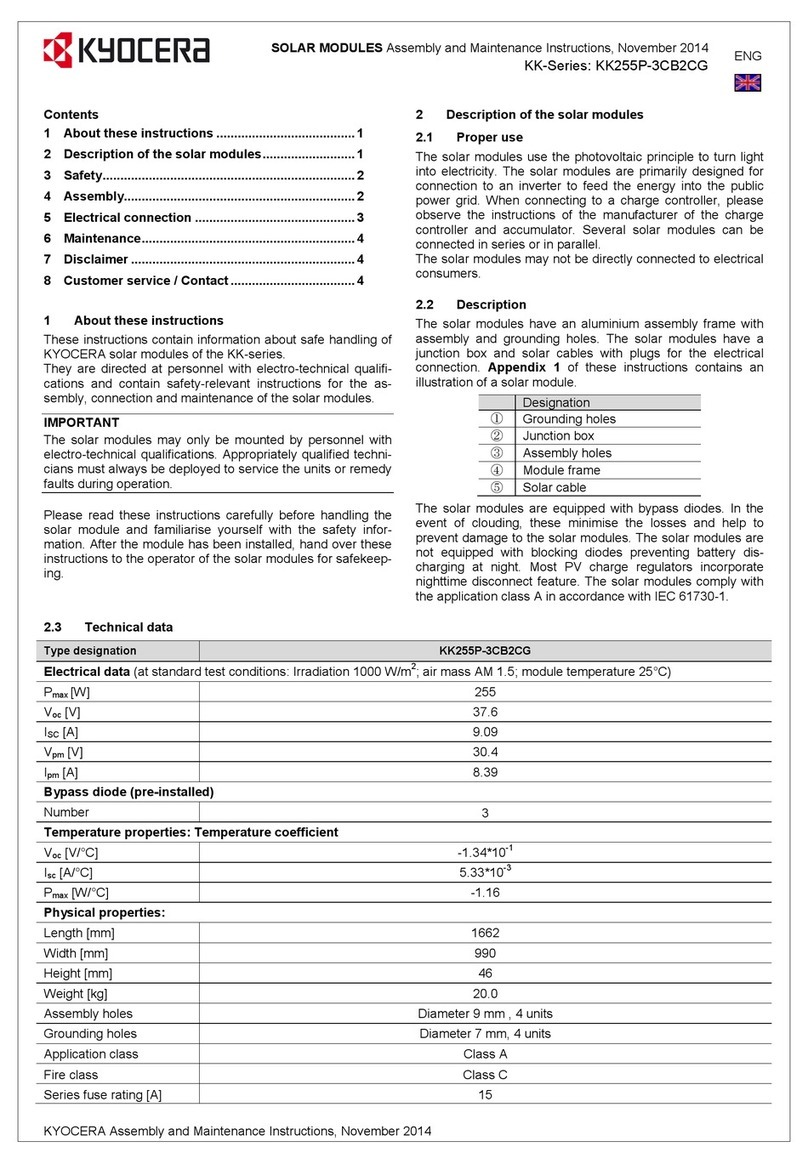

T ble.2 Kyocer KD Series Module Specific tion

Electric l Ch r cteristics : @ STC

Model Ty e KD135SX-UPU

Rated Power, Watts (Pmax) (W) 135 ±5%

O en Circuit Voltage (Voc) (V) 22.1

Short Circuit Current (Isc) (A) 8.37

Voltage at Load (V m) (V) 17.7

Current at Load (I m) (A) 7.63

Maximum System Voltage 600

Recommended maximum number of PV

modules connected in series 21

Factory installed By ass Diode (Qty) 8

Series Fuse Rating (A) 15

Therm l Ch r cteristics :

Tem . Coefficient of Voc (V / ℃) -0.80x10-1

Tem . Coefficient of Isc (A / ℃) 5.02x10-3

Tem . Coefficient of V m (V / ℃) -9.20x10-2

Physic l Ch r cteristics :

Length, Inches (mm) 59.1 (1500)

Width, Inches (mm) 26.3 (668)

De th (frame), Inches (mm) 1.81 (46)

De th (including j-box), Inches (mm) -

Weight Pounds (kg) 27.6 (12.5)

Mounting Hole Diameter, Inches (mm) 0.35 (9) Qty-4 cs

Grounding Hole Diameter, Inches (mm) 0.35 (9) Qty-4 cs

A lication Class Class A

NOTES

(1) Standard Test Conditions of irradiance of 1000 W/m2,

s ectrum of air mass 1.5, and cell tem erature of 25 deg C.

(2) See module drawing for mounting and grounding hole

locations.

(3) Tolerance of Voc and Isc is +/-10%.

Nut

S ring washer

Flat washer

Ground conductor

Cu washer

Star washer

Aluminum frame

Flat washer

Bolt

Nut

S ring washer

Flat washer

Ground conductor

Cu washer

Star washer

Aluminum frame

Flat washer

Bolt

Nut

S ring washer

Flat washer

Star washer

Ground lug

Bolt

Aluminum

frame

Nut

S ring washer

Flat washer

Star washer

Ground lug

Bolt

Aluminum

frame