KYOCERA Assembly and Maintenance Instructions, March 2010

4.4 Mounting the solar module

Please observe the following during assembly:

•A clearance of at least 15 mm needs to be kept be-

tween the module frame and the attachment surface.

This allows the cool ambient air to circulate below the

solar module. This is necessary for optimum perform-

ance in all application ranges.

•There should be a clearance of at least 3.2 mm be-

tween the individual module frames to allow heat-

related expansion.

•The solar modules can be installed in either an up-

right or landscape position.

•If high accumulations of snow on the lowest module

row occur on site, the lower part of the frame may be

damaged when slipping snow is piled up there. This

can be avoided by e.g. attaching support parts at the

lowest modules.

•When selecting the material for the support structure,

pay attention to the electrochemical series in order to

avoid galvanic corrosion between different kinds of

metal.

•Fasten modules firmly to a support structure designed

to withstand the local wind and snow loads

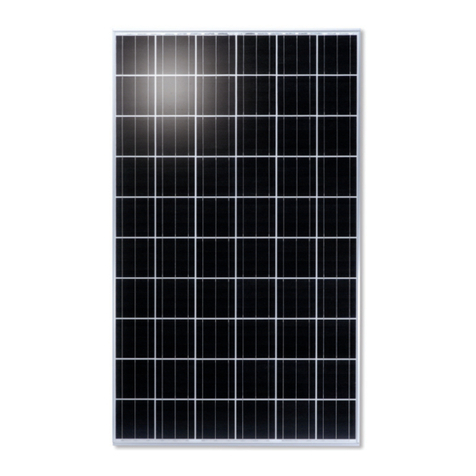

4.4.1 Screw attachment

Assembly material

•Stainless steel screws, diameter 8 mm (4 units)

•Nuts with locking teeth (4 units)

NOTE

No holes may be drilled into the module frame.

Procedure

9Please see the drawing in Appendix 1 of these

instructions for the positions of the mounting holes.

9Drill the required assembly holes to the support

structure.

9Tighten the screws with adequate torque (usually

12.5 Nm) to securely attach the solar module to the

supporting frame. As adequate torque figure depends

on selected bolt nuts, follow the manufacturers'

recommended numbers.

4.4.2 Clamps

Assembly material

•Rustproof module clamps (at least 4 units).

•Please observe the information provided by the

manufacturer when selecting the clamps.

NOTE

The module clamps

- must not bend the module frame.

- must not touch the front glass.

- must not cast a shadow on the front glass.

- must not damage the surface of the frame.

- must be at least 40 mm long respectively.

- must overlap the module frame by at least 7 mm.

- must cover the module frame by min. 360 mm² respectively.

Minimum clamp length for each overlap:

Procedure

9Define the positions of the clamps based on the

drawings in Appendix 2.

9Tighten the module clamps to the torque stated by

the clamp manufacturer.

9Fasten modules firmly by clamps designed to with-

stand the local wind and snow loads.

4.4.3 Assembly to insertion system

When mounting the modules to an insertion system, follow

the instructions in the drawings in Appendix 2. Please ob-

serve the information provided by the manufacturer.

5Electrical connection

5.1 Safety information relating to the electrical

connection

5.2 Wiring of the solar modules

NOTE

The maximum system voltage of solar modules connected to

each other may not exceed 1000 VDC. When designing the

system, please note that the module voltage increases when

the temperatures are low. Do not connect the modules in

parallel without max. over current protection.

Under normal conditions, solar modules can supply higher

currents and/or a higher voltage than reported at the stan-

dard test conditions (see chapter 2.3 “Technical Data”).

Therefore, when determining component voltage ratings,

conductor current ratings, fuse sizes, and the size of controls

connected to the output of the solar modules, the stipulated

values of ISC and Voc should be multiplied with a factor of 1.25.

Only interconnect modules of the same type within a system.

The solar modules are equipped ex-works with 4 mm2-solar

cables. The solar cables have Multi-Contact® PV-3-plugs.

These plugs are designed for series wiring only. Always use

special solar cables with a diameter of at least 4 mm² and

Multi-Contact® PV-3-plugs for further series or parallel wiring.

When wiring, proceed as follows:

•Ensure the poles are connected correctly and that the

plugs are connected properly without gaps

•Observe the minimum bending radius of 24.5 mm of

the solar cables that are used.

5.3 Connection of the solar modules

Please observe the information provided by the manufacturer

of the inverter when connecting the solar modules to an

inverter.

overlap [mm] 7 7.5 8 8.5 9 10

minimum

length [mm] 51.5 48 45 42.4 40 40

Only specially trained and qualified personnel

may make the electrical connection.

Hazard!

Potentially fatal risk if live parts are touched.

•Never disconnect or connect electrical con-

tacts when under load.

•Only use dry, insulated tools for the electrical

assembly work.

•Never touch live parts with bare hands.

•Cover the solar module during installation

with opaque foils or materials.

•Do not wear any metal jewellery.

KYOCERA Assembly and Maintenance Instructions, March 2010

5.4 Grounding of the solar modules

To minimise the risk of an electrical shock, the frames of the

solar modules should be grounded.

Assembly material

•stainless steel screw, diameter 8 mm with serrated

washer and nut

•suitable grounding cable

NOTE

Ensure that the anodised layer of the frame is penetrated and

a secure electrical contact is created with the frame.

Procedure

9Please see the drawing in Appendix 1 of these in-

structions for the positions of the grounding holes.

9Screw the grounding cable firmly to one of the

grounding holes using the stainless steel screw and a

min. torque of 8 Nm.

6Maintenance

Only specially trained and qualified personnel

may service the solar system.

KYOCERA solar modules are designed for long-term service

and are almost maintenance-free.

6.1 Safety information relevant for maintenance

6.2 Cleaning the solar module

When the slope is adequate (> 15 degrees), the solar mod-

ules do not need to be cleaned thanks to the self-cleaning

effect of the rain. If heavily soiled, clean with plenty of water,

a mild detergent and a soft cloth/sponge.

6.3 Solar module maintenance

The system should be inspected once a year with regard to

the following:

•Secure hold and no rust on any of the attachments

•Secure connection, cleanliness and that all cable con-

nections are free of corrosion

•Soundness of cables and front glass

7Disclaimer

KYOCERA’s “Limited Warranty for Photovoltaic-Modules”

does not apply if this assembly and maintenance instruction is

not strictly observed. KYOCERA will not assume any liability for

damage arising from improper use, wrong assembly, opera-

tion or maintenance.

8Customer service / Contact

KYOCERA Fineceramics GmbH

Solar Division

Fritz-Mueller-Strasse 27

D-73730 Esslingen / Germany

•for technical questions:

Tel: +49 (0)711-93934-998

Fax: +49 (0)711-93934-861

•for general questions:

Tel: +49 (0)711-93934-999

Fax: +49 (0)711-93934-950

You will find more information and the latest data sheets,

warranty conditions, certificates etc. in the download

section of our website: www.kyocerasolar.eu

Warning!

Risk of falling when working on roofs.

•Use suitable fall protection equipment.

•Observe the accident prevention regulations.

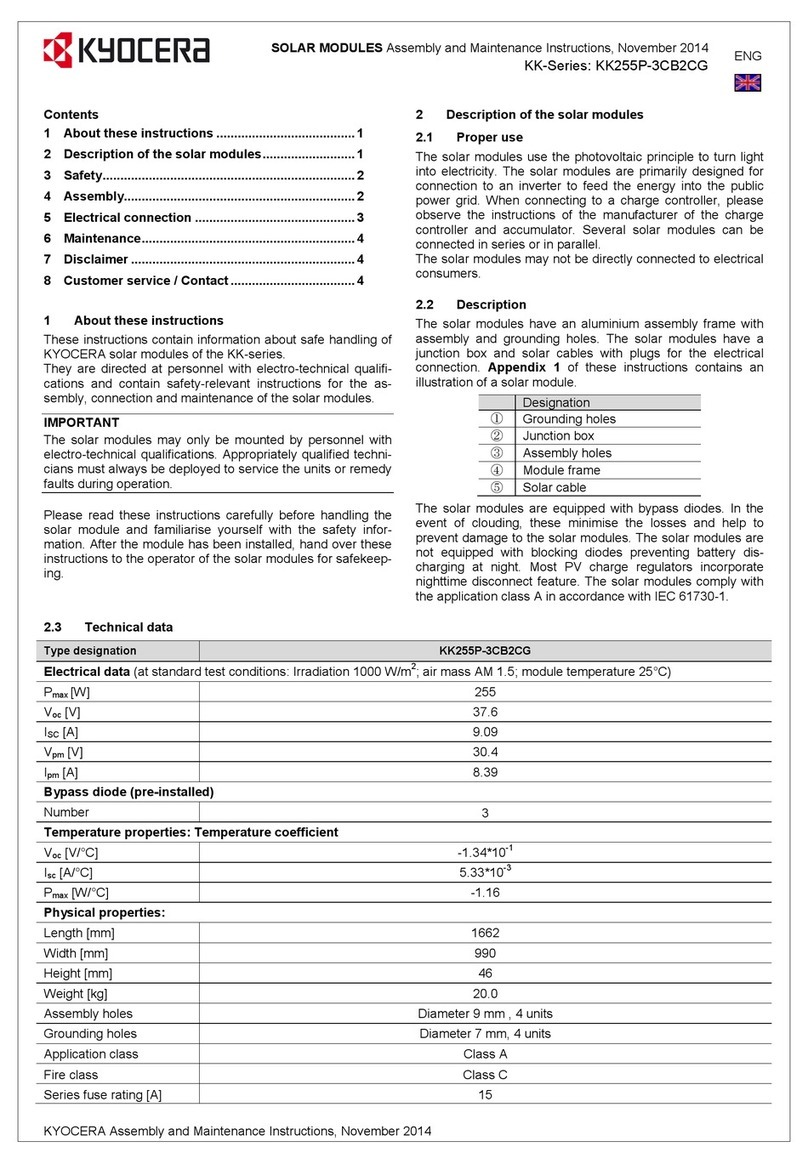

Appendix 1

cGrounding holes

dJunction box

eAssembly holes

fModule frame

gSolar cable