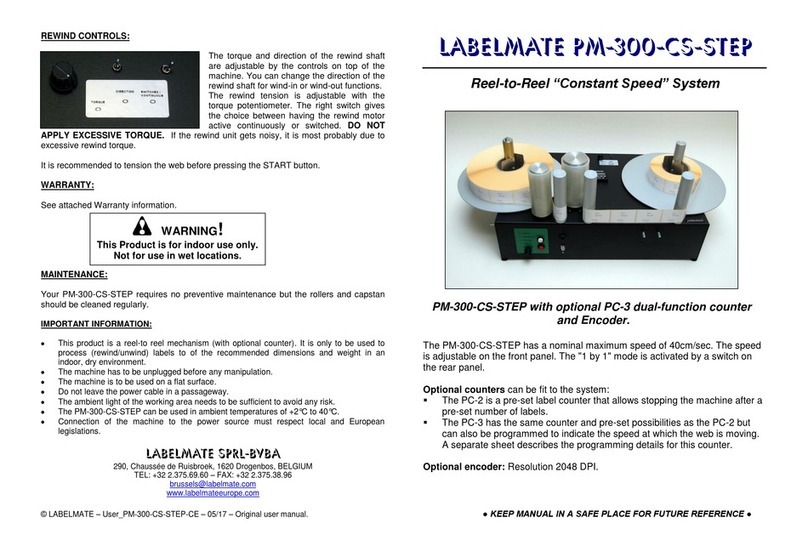

SPECIFICATIONS:

Max. Label Roll Weight: 12Kg (26.5Lb)

Max. Label Roll Size: 400mm (16") diameter

Power Supply: Input: 220-240VAC – 50-60Hz.

Output: 24VDC – 4.17A

SET-UP:

CAT-40G-TA: First install the tension arm referring to the enclosed TA User Manual.

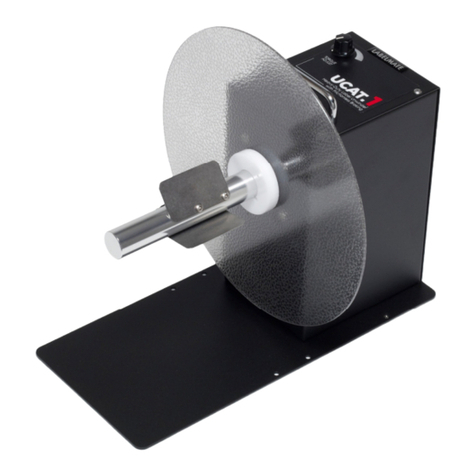

1. Mount the 400-mm (16") diameter Flange Plate onto the "Quick-Chuck" Core

Holder using the screws provided.

2. Slide the "Quick-Chuck" and Flange Assembly onto the CAT-40G Motor Shaft

allowing for clearance to the Chassis and Motor Screws. Tighten the Allen screw

to secure the "Quick-Chuck" and Flange Assembly onto the flat part of the Motor

Shaft

3. Set the CAT-40G in place near the label exit slot of the printer.

4. CAUTION: AVOID ACCIDENTS. THE CAT-40G WEIGHS APPROXIMATELY

13.6KG (30 POUNDS), SO CHOOSE ONLY A STURDY SURFACE ON WHICH

TO SET THE UNIT.

5. The CAT-40G is bi-directional. It can rewind labels in either direction.

6. Verify that the "DIRECTION" Switch on the CAT-40G Control Panel is in the

"OFF" position.

7. Plug the Power Plug at the end of the wire on the AC Wall Transformer into the

CAT-40G Power Input Jack. Plug the AC Transformer into an appropriate AC

power outlet.

8. The unit is now ready for use.

POWER REWINDING:

1. Place the "DIRECTION" Switch on the CAT-40G Control Panel in the centre

"OFF" position.

2. Slide an empty label core onto the CAT-40G "Quick-Chuck".

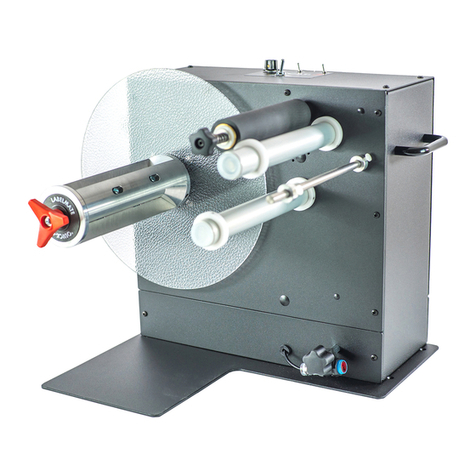

3. Feed the label web from the printer under the Sensor Arm (TA only) and onto the

rewind core, and secure it with a piece of tape.

4. Place the "DIRECTION" switch in the desired position to rewind the labels.

5. Advance the "TORQUE" Control about 1/3-rotation from fully counter-clockwise

as an initial setting.

6. Start your printer and observe how the labels are being rewound.

7. Adjust the "TORQUE" Control as needed to provide more or less rewind force.

The CAT-40G's amplified-torque motor will provide a nearly constant rewind

speed as the roll diameter grows. If necessary, adjust the rewind TORQUE

setting.

EXTERNAL HALT CONTROL:

The External Halt Control jack on the CAT-40G is for use with external devices

capable of providing an open circuit halt command. A 3.5mm control cable is

necessary for use (not included).

Use of the External Halt Control circuit is optional. With No Connection (nothing

plugged into the External Halt Control jack), the Rewinder will function as described

above.

With Pin 2 and Pin 3 of the External Halt Control circuit closed (connected together

using a 3.5mm dual circuit plug), the CAT-40G will operate. When the External

Circuit is opened, the CAT-40G will stop.

3.5mm “EXTERNAL HALT CONTROL” Plug (Dual Circuit Plug)

Contact CLOSED=RUN Contact OPEN=HALT

Pin 1 - No connection (NOT USED)

Pin 2 - Normally Closed (NC) contact

Pin 3 - Normally Closed (NC) contact return

10K

12V

1K D

S

G

10K

"EXT. HALT CONT."

3.5 mm Jack

Dual Circuit

WARNING!

This Product is for indoor use only.

Not for use in wet locations.

231