SPECIFICATIONS:

Size: (Overall envelope) HW D – 13”x33”x9” (330x584x229-mm).

Power: Universal Power Supply: 100-240vac 50-60Hz, 50va.

Roll W idth: 6.5” (170-mm). Depending on Roll Diameter.

Core Diameter: RR-330 Unwind & Rewind:3” (76-mm).

RR-330A Unwind: 3” (76-mm). Rewind: 1”-4” (25-100-mm).

RR-330 / RR -33 0-A SE T-UP:

Plug the Power Supply Output Cable to the Power Jack on the Rear Panel

of the RR-330. Plug the Power Supply into a suitable AC Power Outlet.

Rotate the SPEED Control to minimum (full counter-clockwise

position). Place the Power Switch on the rear of the RR-330 to the

“ON / 1” position.

O P E R AT I O N :

RRC and RRR have the same basic function.

Plac e the “STOP / RUN” S wi tc h in the STO P Position.

Place your Roll of Labels on the Roll Holder at the left of the Unit. The

Take-Up Spindle on the right rotates in a counter-clockwise direction. Note

that you can “Wind-In” or “Wind-Out” according to which way you place the

Label Roll on the Roll Holder, right-side-up or upside-down.

There is a Buttery Screw on the unwind Core Holder Hub.

Tightening this Screw will increase the braking eect (Unwind tension).

Unscrew the Buttery Screw for less tension or if the Core of the unwind

roll is too tight on the unwind Hub.

The plastic Ring on the first paper guide needs to be used only if

the unwind roll is unevenly wound to begin with. Setting the Ring at the

proper height will correct the unevenness of the Roll on the rewind side. It

is recommended to lower the speed if the unwind Roll is very uneven.

The machine will stop when out of labels. To re-start, load labels

on the Unwind Core Holder, and place the STOP/RUN Switch to STOP.

Thread the labels through the Photo Sensor Gap between the Idler Rollers.

Place an empty label Core (not included) over the Take-Up Spindle and

secure the Label Web using a piece of tape. Start by switching to “RUN”.

THE UN I T W I L L NOT R U N IF T H E R E IS NO T H I N G IN T H E S E N SOR.

WARNING

This product is for indoor use only.

Not for use in w et locations.

Unplug unit before removing waste material or

performing any cleaning or maintenance services.

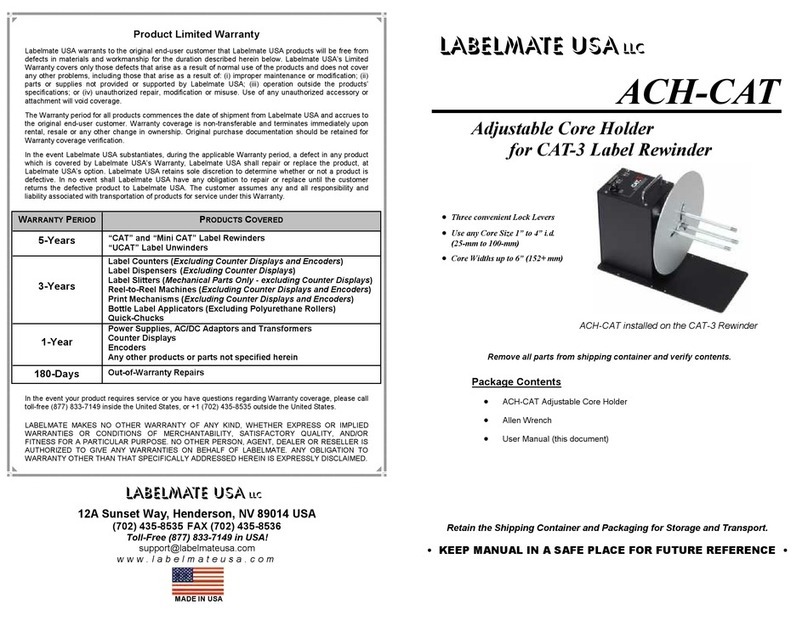

RR -3 30- A ON LY: U SIN G THE A DJ USTAB LE COR E H OLD ER (AC H):

Unlock the three Locking Levers underneath the take-up Flange by

turning them clockwise. If the Levers are diicult to grasp, pull straight

down on the Lever Arm and reposition the Arm so it is more or less

perpendicular to the metal Hub.

While holding the Take-Up Flange, rotate the Black Plate underneath

the Take-Up Flange to bring the “Fingers” together.

Place your Take-Up Core over the “Fingers” about half-way down and

rotate the Black Plate again to bring the “Fingers” in contact with the Core.

Lock the Locking Levers by turning them counter-clockwise (looking from

the top). Reposition the Lever Arms if necessary by pulling straight down

and rotating them to a convenient position.

Push the Take-Up Core all the way down on the “Fingers”. The

Core should now be held tight on the “fingers”. If it’s not tight enough, re-do

the operation.

For easy removal of the roll from the ACH, release one of the Locking

Levers temporarily, remove the Roll and re-tighten the Locking Lever.

Once the ACH diameter is set, you can put the next empty core on

the ACH without readjusting the Locking Levers.

N O T E :

Keep the Unwind Plate clean of particles and label adhesive. The

Bypass Switch on the side of the Unit will cause the RR to run at full

speed, approximately 10% faster than the maximum Adjustable Speed.

PH OTOC E LL A DJU STM ENT:

The sensitivity of the Photocell that detects the Labels and triggers the

Counter Display should be calibrated for the labels being counted. Here’s

how: Place the RRC STOP / RUN Switch in the STOP Position. Place a

Label Liner ONLY (no label) in the Label Sensor Gap. Using a small flat-

bladed screwdriver, adjust the Photocell Adjust Control until the green

Photocell Adjust LED illuminates. –OR– Adjust Photocell Adjust control for

3- to 5-VDC at the Photocell Test Jack 3.5-mm Plug.

Counter and Encoder option:

If you have the Encoder option for the RRC-330/330-A please see

the enclosed Encoder Instruction Sheet for setup and operation.

When you switch to / from the Counting to the Encoding (Linear)

Mode you must remember to reset the Counter each time.