LABORIE Portascan3D Service Manual PTS3D-SM01 V3.0 3

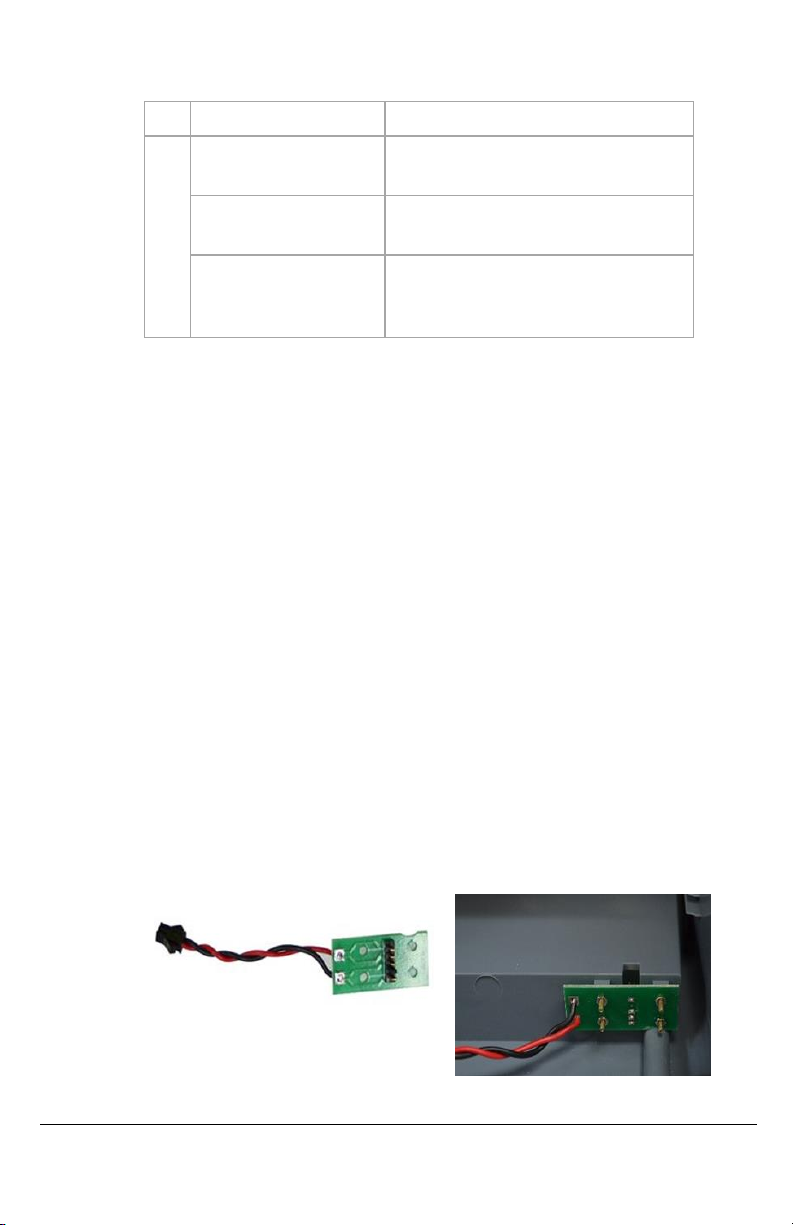

NOTE: Please refer to

Fig. 8

for the cable connection.

2. PRINCIPLE OF OPERATION

The main parts of the product include main board, LCD, touch screen,

3D ultrasound probe, thermal printer and rechargeable lithium battery.

The operation principle is describe in Fig.1.

3D ultrasound probe consists of 2.5 MHz transducer, two step-motor,

mechanical transmission mechanism, probe housing and cable. The

slave motor drives the transducer to do 120°sector scanning. Main

motor drives the motor and transducer to do 180°axial rotating. Then

3D scanning is achieved.

The transducer emits ultrasound wave into the human body with

excitation of electric pulse and then receives the reflected signals from

the bladder. The urine inside the bladder is low echo area and forms

strong reflection at the wall of the bladder. Amplitude discrimination

method can easily help to recognize the reflected waves at the

bladder anterior and posterior walls and then calculate the distance

between the two walls. Cross section area can be calculated with

integral calculation method after the scanning is obtained. Then

control signal is emitted for 15°rotation of the main monitor and then

the scanning for next cross section is initiated. The bladder volume can

be calculated with integral calculation method after the scanning of

the 12 cross sections is finished.

To guarantee the correct probe location, pre-scanning function is

designed to show the ultrasound image of the bladder. Users may

adjust the position of probe to make sure that the whole bladder is

within the sector scanning area, and then start scanning. A measuring

result can be obtained based on these steps.

The product utilizes lithium battery for power supply considering the

operation requirements of ward. To ensure that the product can work

continuously for enough long time, economical and effective power

consumption was thoroughly considered when power management

circuit was designed. When the product has not been operated for a

long time after switching on, the LCD back light will be switched off

automatically. Automatic Power-off function is also designed to

effectively utilize battery power.

Measuring result output can be achieved through thermal printer or

inner memory.