This phase, called drain down, will allow a complete ice melting and the drain of the resulting water.

* The actual defrost frequency depends on the selection I/II: in mode I, the reference parameter is DFR while in mode II it’s IIDF.

6. EVAPORATOR FANS

6.1 During thermostatic control, the evaporator fans are controlled by parameter *FTC, FT1, FT2 and FT3.

With FTC=YES you enable an optimised fan control; the fans will operate in conjunction with the compressor and after the compressor

has stopped, the fans will be activated according to the time FT1 (recovery of accumulated cooling), after that they will be stopped for

the time FT2 (energy saving). When FT2 has elapsed, the fans will run for the time FT3 (whirling air stratifications).

Example: FT1=30, FT2=4, FT3=1. With those values the fans will cut-in together with the compressor and will stop 30 seconds after the compressor has

stopped; now, a 4 minute OFF and 1 minute ON cycle will take place till the compressor starts again.

With FT2=0 the fans will always be active. Viceversa, if FT2 is different from 0 and FT3=0, the fans will always be off.

With FTC=NO the optimised control is excluded, so the fans will run all the time.

6.2 If the LF28 is connected to a door switch and door switch control is enabled (DS=YES), during thermostatic control if the door is

opened, the fans will be stopped immediately.

6.3 During defrost, the fans are controlled by parameter FID; with FID=YES the fans remain on all through defrosting. With FID=NO,

the fans will be stopped and will only re-start when the conditions in paragraph 6.4 have been met.

6.4 After defrosting, if probe T2 is active (T2=YES), temperature FDD provides evaporator fan re-start. So the evaporator fans will not

run until the evaporator has a temperature lower than FDD. Viceversa, if either probe T2 is not active (T2=NO) or, after defrost

termination, such condition doesn't occur within the time FTO, the fans will however be switched on again.

* The way the fans will be controlled depends on the selection I/II: in mode Ithey work according to FTC, while in mode II the fans

work according to IIFT.

7. ALARMS

With LF28, correct operation of the refrigerator and thermostat may be monitored by a wide range of functional and diagnostics alarms,

individually selectable by means of the relevant parameters. The alarm warnings are given on the display through explicit indications

(see following par.), the auxiliary relay contacts open (if present in model and if OAU=ALR) and intermittent buzzer sounding. During an

alarm, by pressing any button, the buzzer is muted. Then, if the alarm persists, the buzzer will be periodically switched on for 20 seconds

every 60 minutes, until the alarm ends (the display indications remain on all the time). The repeated acoustic warning applies to all alarms

with the exception of the condenser cleaning alarm. Operation of the various elements is given in detail below.

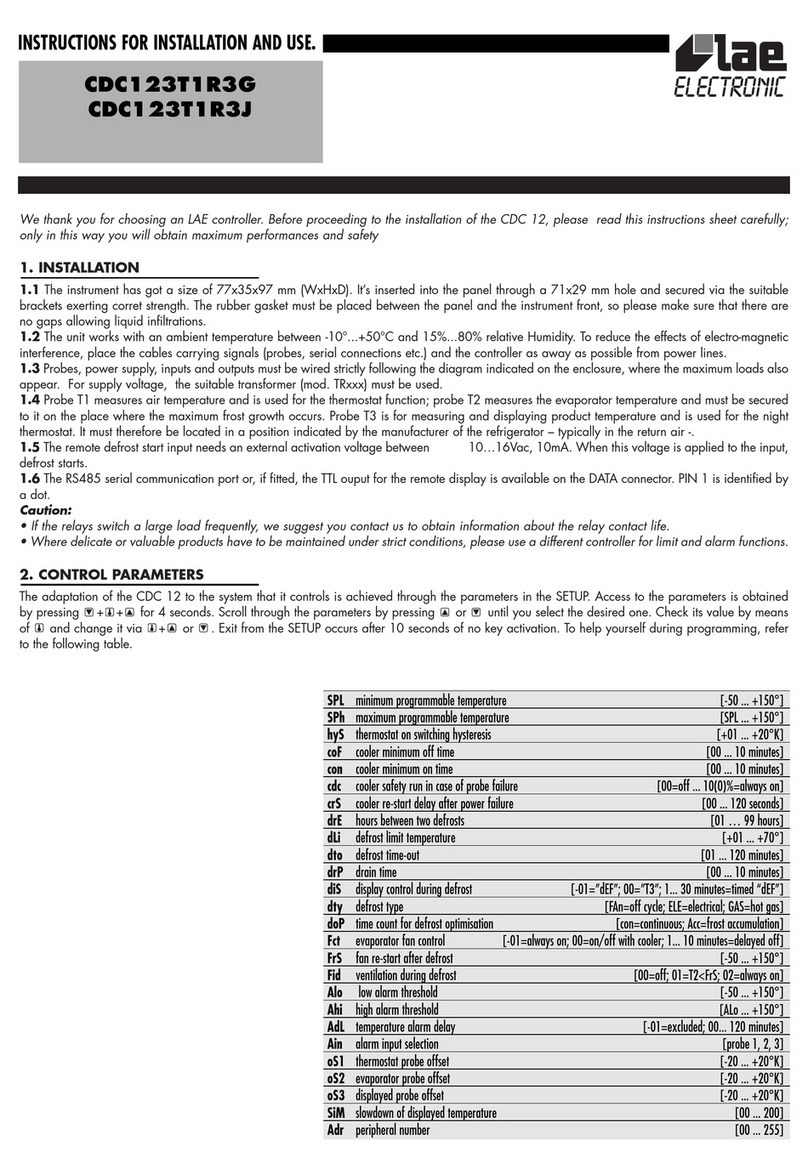

7.1 ATL establishes the alarm differential for temperatures below set point, ATH the alarm differential for temperatures above set point

+ hysteresis. Putting one or both differentials to 0 cuts out the corresponding alarm.

Example: SP= -20, HYS= 2.0, ATL= -5.0, ATH= 5.0; the alarm thresholds are set at –25°(-20-5) and –13° (-20+2+5).

The alarm warning may be immediate or delayed by the time ATD whenever this is greater than 0. The indication for high temperature

and for low temperature alarm blinks on the display. The alarm indication remains stored in the display, even when the alarm is over,

until you acknowledge the alarm manually by pressing any button.

The high temperature alarm is bypassed during defrosting.

7.2

If a suitable door switch has been connected to detect the door status and door switch input control has been enabled (DS=YES), the door

open alarm function is enabled. In this way, if the door remains open the controller will react after the time delay set with ADO by displaying

the alarm source through the indication .

7.3 To monitor the condensing unit temperature to avoid gas pressure from getting too high, it’s necessary to secure the probe T3 to

the condenser firmly (see 1.4) and enable condenser probe control (T3=YES). If there is a second condensing unit in the plant and this

should be monitored (OAU=2CU), it’s necessary to secure the sensor T4 in the same way as the sensor T3 and to enable it with T4=2CU.

Parameter AHT determines the condenser temperature alarm threshold for one or both probes and parameter AHM determines the

reaction following the temperature rising over AHT. With AHM=ALR the only reaction will be the buzzer sounding, being displayed

and the alarm relay switched on. Alternatively, with AHM=STP, besides the alarm indication the compressor will be stopped immediately

and defrosts suspended.

With AHM=NON, all functions related to the High Temperature and High Pressure alarm (par. 7.4) are inhibited.

7.4 The correct operation of the condensing unit may not only be monitored via temperature (par. 7.3), but also through a safety

pressure switch. In this case, the digital input DI2 is to be used by programming DI2=HPS; in this way, when the pressure switch opens,

a high pressure alarm will be displayed combined with the alarm function programmed with AHM (ALR or STP).

7.5 Assigning a value greater than 0 to the parameter ACC enables the indication for periodic cleaning of the condenser. Subsequently,

when the count of compressor hours of operation reaches the equivalent in weeks set with ACC, an indication for cleaning appears on

the display.

Example: with ACC=16 there is a warning once every 16x7(weeks)x24(hours)=2688 hours of compressor operation, so, assuming for this an operation

with 5 minutes On and 5 minutes Off - after approx. 32 weeks.

In order to clear the time counter, follow the prescribed procedure in paragraph 2.3.

7.6 Upon failure of probe T1 or, if enabled, probes T2, T3 or T4, probe failure is signalled with the blinking indication or or