ELF 01.10.2019

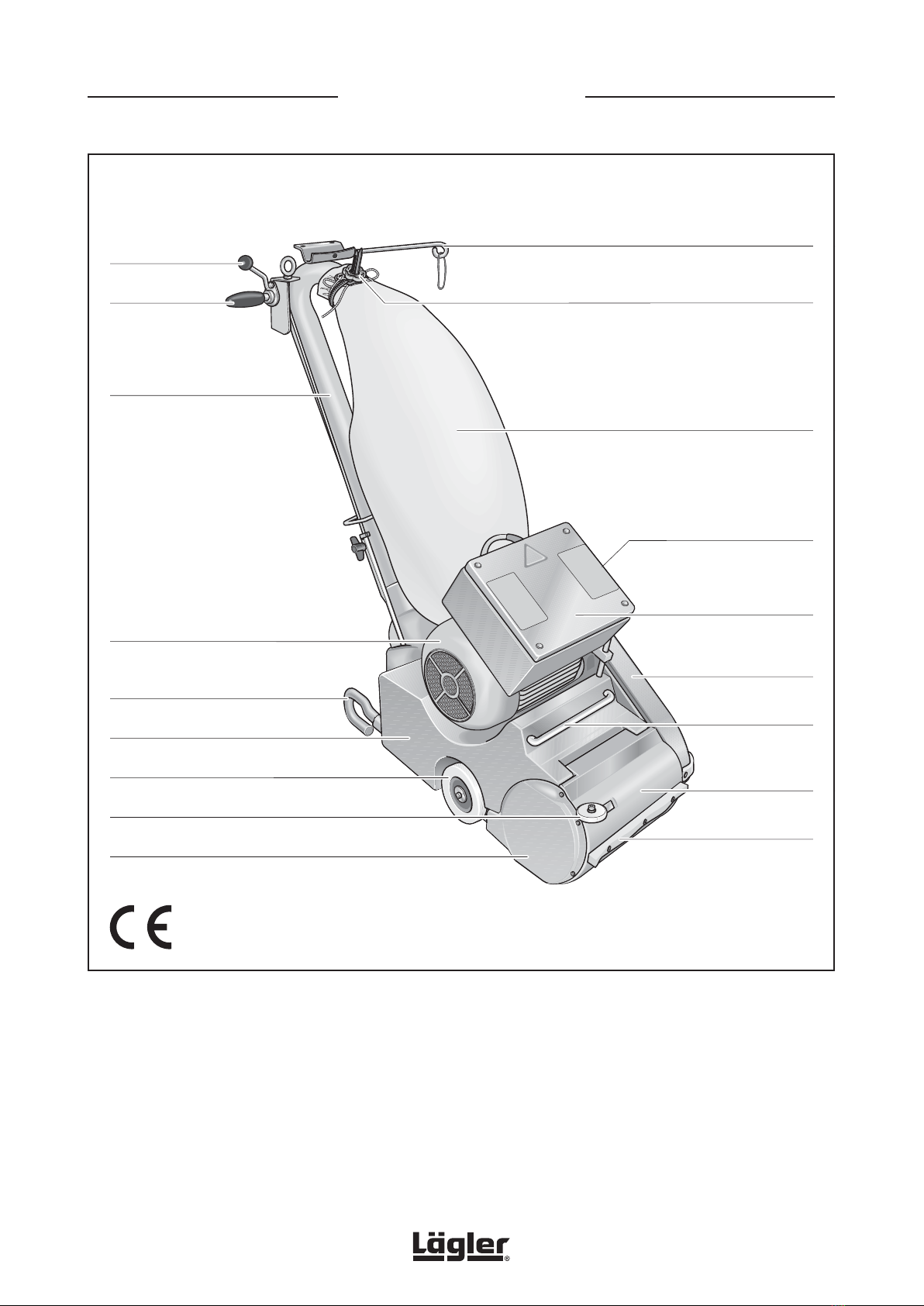

English / Englisch

CONTENTS

1 Introduction ....................................................................................................................................................................5

1.1 Features of the machine ...............................................................................................................................................5

1.2 Description of the machine ..........................................................................................................................................5

1.3 Intended use of the machine ........................................................................................................................................5

1.4 Safety devices ................................................................................................................................................................6

1.5 Machine configuration ..................................................................................................................................................6

1.5.1 Basic equipment ..........................................................................................................................................................6

1.5.2 Optional equipment .....................................................................................................................................................7

1.5.3 Wearing parts and safety-related parts ...................................................................................................................7

2 Hazard warnings and safety instructions ..................................................................................................................8

2.1 Hazard warnings ............................................................................................................................................................8

2.2 General safety instructions ........................................................................................................................................13

3 Technical data .............................................................................................................................................................15

3.1 Data on type plate .......................................................................................................................................................15

3.1.1 Machine type plate ...................................................................................................................................................15

3.1.2 Motor type plate ........................................................................................................................................................16

3.2 Machine data ...............................................................................................................................................................17

4 Commissioning ............................................................................................................................................................19

4.1 Preparing the machine for operation ........................................................................................................................19

4.2 Connecting the power cable ......................................................................................................................................21

4.3 Switching on the machine ..........................................................................................................................................22

4.3.1 Machines with single-phase AC motor (mains voltage 230 V and 220 V) ...........................................................22

4.3.2 Machines with three-phase AC motor (mains voltage 400 V) ..............................................................................23

4.3.3 General .......................................................................................................................................................................24

4.4 Switching off the machine ..........................................................................................................................................24

5 Working with the ELF ..................................................................................................................................................25

5.1 Application tips ............................................................................................................................................................25

5.2 Changing the abrasive ................................................................................................................................................26

5.2.1 Sanding drum for clamping abrasive paper ...........................................................................................................26

5.2.2 Centrifugal sanding drum .........................................................................................................................................29

5.3 Regulating the sanding pressure ...............................................................................................................................30

5.4 Sanding with the machine ..........................................................................................................................................31

5.5 Emptying the dust bag .................................................................................................................................................32

6 Transport and storage .................................................................................................................................................34

6.1 Dismantling the machine before transportation ......................................................................................................35

6.2 Assembly after transportation ...................................................................................................................................37

6.3 Storage .........................................................................................................................................................................39

2