Laguna Tools Robland X31 User manual

Other Laguna Tools Industrial Equipment manuals

Laguna Tools

Laguna Tools Smartshop II Series User manual

Laguna Tools

Laguna Tools Swift Series User manual

Laguna Tools

Laguna Tools MCNC Creator I-23 User manual

Laguna Tools

Laguna Tools SmartShop SS2 User manual

Laguna Tools

Laguna Tools ML353 User manual

Laguna Tools

Laguna Tools Swift Series User manual

Laguna Tools

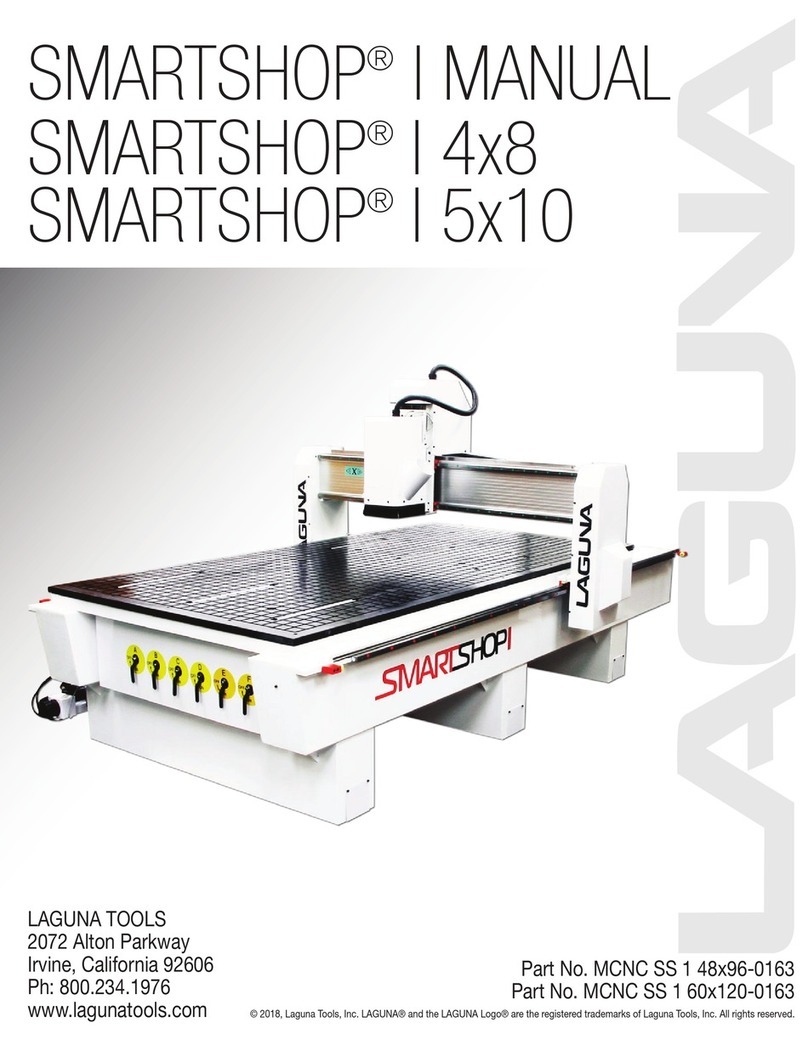

Laguna Tools SMARTSHOP I MANUAL User manual

Laguna Tools

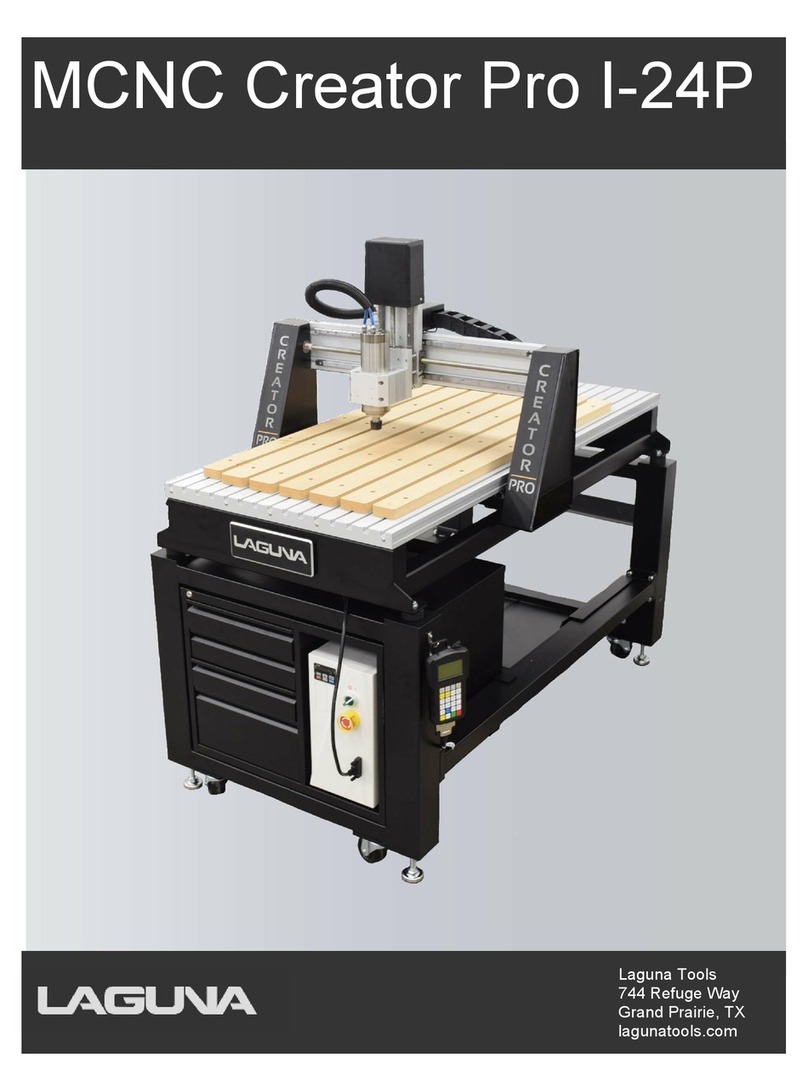

Laguna Tools MCNC Creator Pro I-24P User manual

Laguna Tools

Laguna Tools Smartshop SUV User manual