10

a) Szyba przednia jest zabrudzona lub uszkodzona (wyczyścić lub filtra samościemniającego, a następnie wyjąć szybkę w kierunku

wnętrza przyłbicy.

wymienić).

UWAGA! Wymiany i instalacji wkładu filtrującego, powinien dokonywać

b) Czujniki są zabrudzone (wyczyścić powierzchnię czujników).

wykwalifikowany i przeszkolony personel.

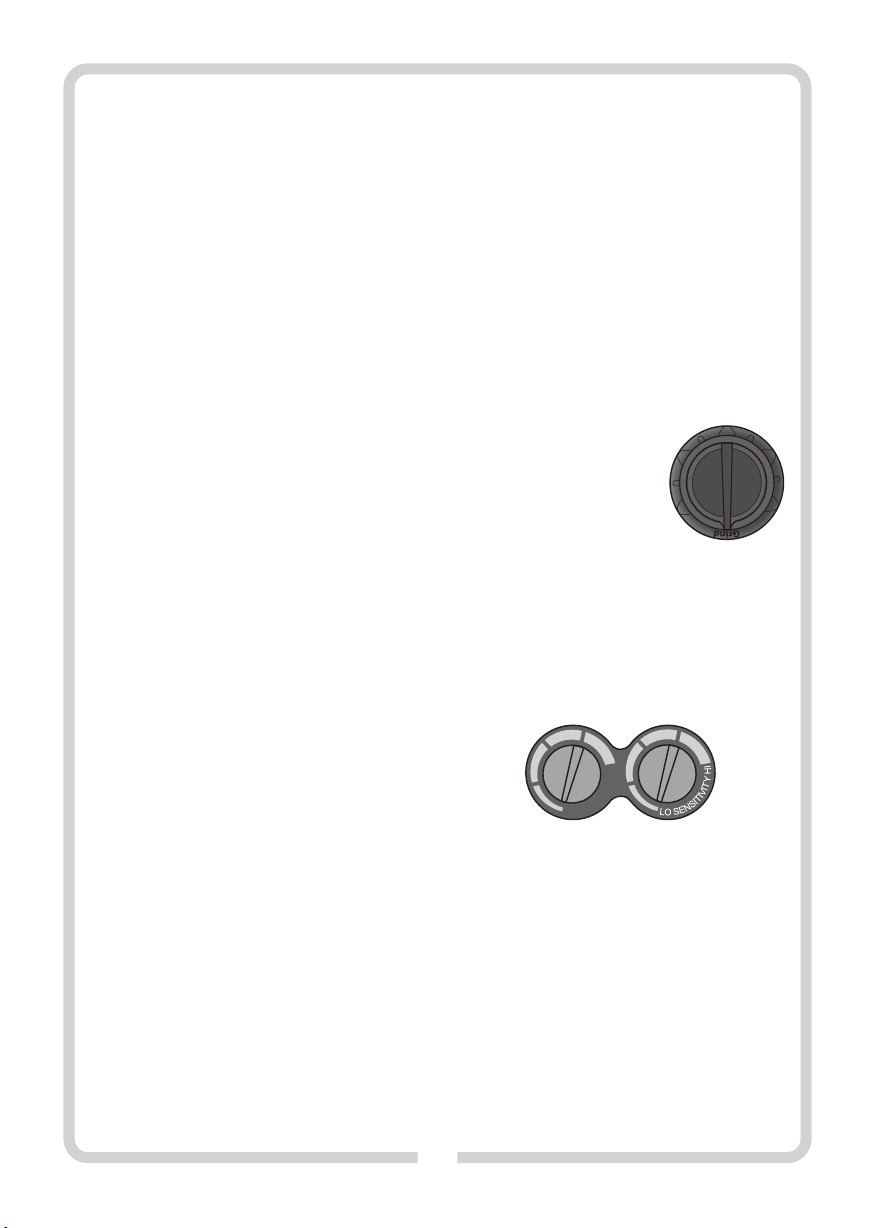

c) Prąd spawania jest zbyt niski (przestawić przełącznik czułości do

położenia "HI").nWymiana baterii zasilających filtr

Jeśli zaświeci się wskaźnik diodowy oznaczony „LOW BAT” należy wymieć

d) Baterie zasilające wyczerpały się (wymienić baterie).

baterie na nowe.

3. Wolna reakcja Baterie umieszczone są w dwóch niezależnych komorach na kasecie

a) Temperatura robocza jest zbyt niska (nie używać przyłbicy w filtra. W celu wymiany baterii należy obrócić i zdjąć pokrywę komory.

temperaturze poniżej -5°C). Zużytą baterię wyjąć z komory i zastąpić ją nową.

4. Słaba widoczność Zamknąć pokrywę i powtórzyć opisaną powyżej operację z drugą

a) Szyba przednia / wewnętrzna i/lub filtr są zabrudzone (wyczyścić baterią.

lub wymienić ). UWAGA! Baterie wymieniać tylko parami. Nie mieszać baterii zużytej z

b) Oświetlenie otoczenia jest niewystarczające (oświetlić nową.

prawidłowo).

c) Nieprawidłowo ustawiony stopień zaciemnienia filtra (sprawdzić

zalecane stopnie zaciemnienia podane w tej instrukcji i ustawić

prawidłowy).

5. Przyłbica zsuwa się z głowy

a) Opaska na głowę nie jest wyregulowana prawidłowo

(wyregulować opaskę).

10. KONSERWACJA I PRZECHOWYWANIE:

Należy regularnie i starannie dokonywać prac konserwacyjnych

przyłbicy. Pozwoli to na zachowanie maski w dobrym stanie

technicznym.

Wyrób należy przechowywać w dostarczonych opakowaniach

jednostkowych w ciemnym, suchym, przewiewnym i zamkniętym

pomieszczeniu. Podczas przechowywania, nie przekraczać zakresu

temperatur od -20 st. C. do +70 st. C. Chronić przed kurzem, pyłem i

innymi zanieczyszczeniami (worki foliowe, torebki itp.) Chronić przed

uszkodzeniami mechanicznymi. Transport - w dostarczanych

opakowaniach jednostkowych, w kartonach, w zamkniętych środkach

transportu.

nCzyszczenie

Filtr czyścić można przy pomocy czystej i gładkiej szmatki lub materiału

bawełnianego.

Nie zanurzać przyłbicy i filtra w wodzie i nigdy nie używać środków

ścierających, rozpuszczalników i detergentów na bazie oleju.

Nie otwierać kasety filtra samodzielnie. Kaseta filtra może zostać

rozmontowana przez autoryzowany serwis lub wykwalifikowaną osobę.

W innym wypadku dojdzie do utraty gwarancji.

nWymiana szybki ochronnej:

W celu zapewnienia wieloletniej bezawaryjnej pracy filtra zabronione

jest używanie przyłbicy pozbawionej poliwęglanowych szybek

ochronnych. Należy regularnie wymieniać frontową szybkę ochronną,

ktora ulega naturalnemu zmatowieniu w wyniku uderzania o nią

odprysków podczas spawania.

W celu wymiany szybki ochronnej należy najpierw wymontować kasetę

OCHRONA ŚRODOWISKA:

UWAGA! Przedstawiony symbol oznacza zakaz umieszczania

zużytego sprzętu łącznie z innymi odpadami (z zagrożeniem

kary grzywny). Składniki niebezpieczne znajdujące się w

sprzęcie elektrycznym i elektronicznym wpływają

negatywnie na środowisko naturalne i zdrowie ludzi.

Gospodarstwo domowe powinno przyczyniać się do odzysku i

ponownego użycia (recyklingu) zużytego sprzętu. W Polsce i w Europie

tworzony jest, lub już istnieje, system zbierania zużytego sprzętu, w

ramach którego wszystkie punkty sprzedaży ww. sprzętu mają

obowiązek przyjmować zużyty sprzęt. Ponadto istnieją punkty zbiórki

ww. sprzętu.

11. OBJAŚNIENIE OZNACZEŃ FILTRA:

MODEL: ADF GX-800S – model filtra samościemniającego;

CAN/CSA Z94.3 – kanadyjska norma bezpieczeństwa;

ANSI Z87.1 – amerykańska norma bezpieczeństwa;

4/9-13 GX 1/1/1/2/379 CE – oznakowanie filtra spawalniczego z

ręcznym ustawianiem stopnia ochrony, gdzie:

4 - nr stanu jasnego; 9 - nr najjaśniejszego stanu ciemnego; 13 - nr stanu

najciemniejszego; GX – kod producenta,

1 - klasa optyczna; 1 - klasa rozproszenia światła; 1 - klasa odchylenia

współczynnika przepuszczania światła; 2 - klasa zależności

współczynnika przepuszczania światła od kąta; 379 - nr normy

europejskiej dotyczącej automatycznych filtrów spawalniczych EN 379,

CE - znak zgodności z dyrektywami nowego podejścia WE.

GX EN 175 F CE – oznakowanie przyłbicy, gdzie: GX – kod producenta,

EN 175 – europejska norma bezpieczeństwa; F – symbol odporności na

uderzenie o niskiej energii; CE - znak zgodności z dyrektywami nowego

podejścia WE.

IMPORTER/UPOWAŻNIONY PRZEDSTAWICIEL:

Profix Sp. z o.o.,

ul. Marywilska 34,

03-228 Warszawa, Polska

Polityka firmy PROFIX jest polityką stałego udoskonalania swoich produktów i dlatego firma rezerwuje sobie prawo zmiany

specyfikacji wyrobu bez uprzedniego zawiadamiania. Obrazki, podane w instrukcji obsługi, są przykładowe i mogą się

nieznacznie różnić od rzeczywistego wyglądu zakupionego urządzenia.

Niniejsza instrukcja jest chroniona prawem autorskim. Kopiowanie/ powielanie jej bez pisemnej zgody firmy Profix Sp. z o.o.

jest zabronione.