1. Usable 5’’ (125

mm) angle grinder’s rated power must be at least

limit is up to 12 000 min-1

(RPM), grinder spindle thread must be

which is common angle

grinder spindle thread in European and other metric system countries

recommended that the grinder be equipped with soft start system and electrical or mechanical

safety clutch.

2. The log peeling and shaping

spindle using its internal reinforced thread

flange

(figure 2, pos. 2) is in use and its

the tool’s fixing thread 5/8”-

32x2 mm (figure 1, pos. 4)

pos. 3). The

seal prevents to avoid tool loosening after angle grinder motor is turnef off.

brake and therefore it is

3. Tool thread connection 5/8”-

flange with a special angle

important to use gloves, because there is a risk to injure operator’s hand against the cutting blades

when the wrench

4. Always disconnect the

1, pos,

2) or when performing any general maintenance activities (such as adjusting or cleaning).

Remove dust, wood resin

5.

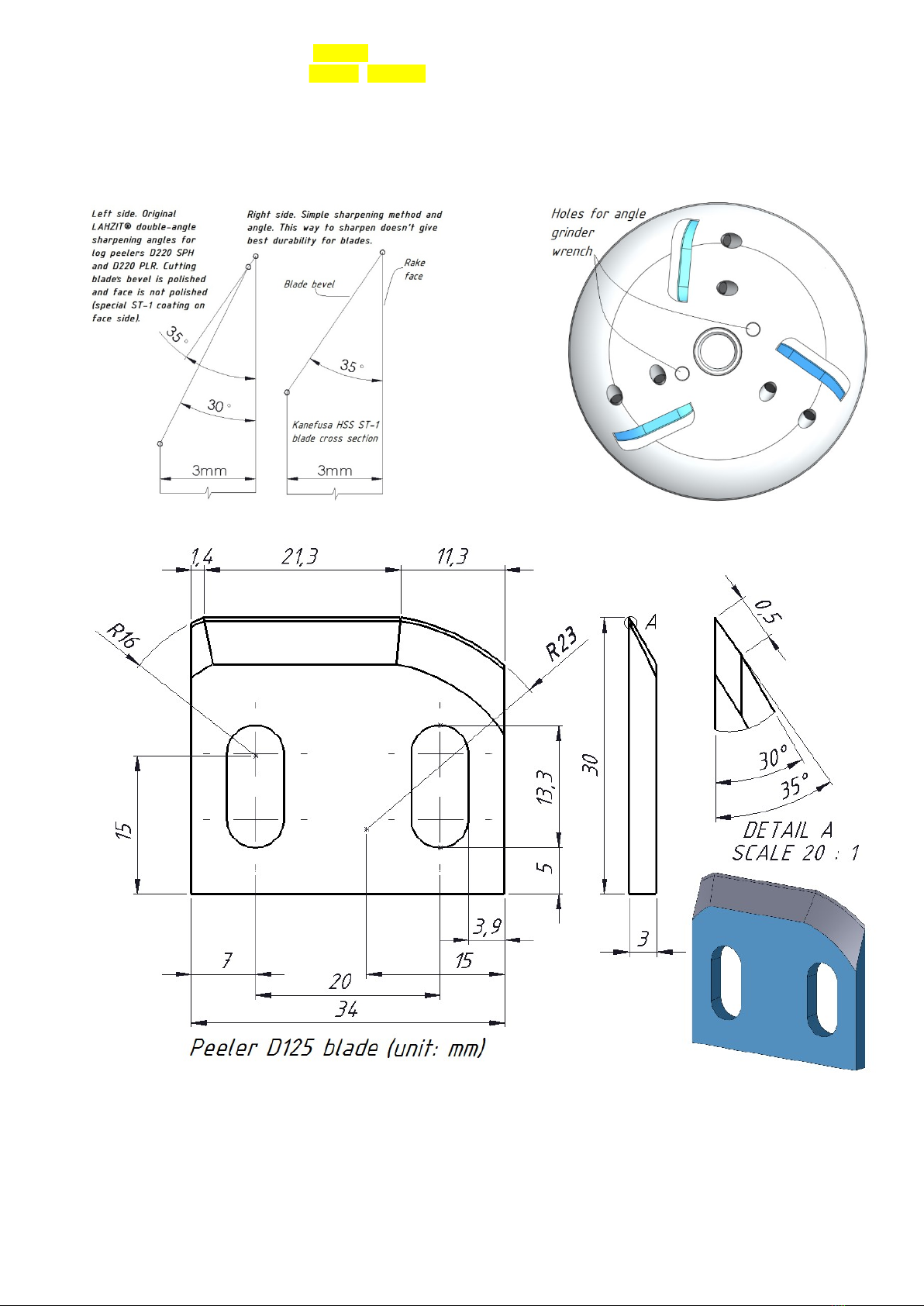

Handle cutting blades with care. After sharpening, the blades can

use gloves! Sharpening

geometry and other related

6. Cutting blades m

ust be adjusted according to peeling process

requires to adjust larger

of blades to 0.5…1.0mm.

Make sure that the cutting blades are equally adjusted (figure 3).

Fig 1.

Complete log peeling and shaping

tool D125 PLR shown with it’

Fig 3.

Principle of peeling and shaping tool D125

must be on the same level. You can check it for example using small plywood piece

leave

3 notches to the same level on the plywood!

mm) angle grinder’s rated power must be at least

(RPM), grinder spindle thread must be

5/8”-

11 (most common in the USA)

grinder spindle thread in European and other metric system countries

recommended that the grinder be equipped with soft start system and electrical or mechanical

tool D125 PLR (figure 1, pos. 1) will be a

spindle using its internal reinforced thread

5/8”-11 (figure 1, pos. 5).

(figure 2, pos. 2) is in use and its

step edge

with diameter 22.23 mm / 7/8’’

like it is shown on the figure 2.

Make sure the rubber seal

before fixing the tool to the grinder’s spindle (figure 2,

always includes spare seal OR 32x

2 mm, rubber mark NBR 70. This

seal prevents to avoid tool loosening after angle grinder motor is turnef off.

this O-ring condition.

must be tightened

until there is no cap between tool body and disc

using special holes for that in tool body (figure 5). I

important to use gloves, because there is a risk to injure operator’s hand against the cutting blades

slip away. Please be very

from the power source when changing

2) or when performing any general maintenance activities (such as adjusting or cleaning).

using a special brass

cleaning tool which includes

Handle cutting blades with care. After sharpening, the blades can

geometry and other related

information is shown in figure 4

ust be adjusted according to peeling process

(up to 2.0

mm), the wood surface finishing needs adjustment

Make sure that the cutting blades are equally adjusted (figure 3).

Complete log peeling and shaping

Fig 2. Attatching shem

shaping

tool D125 PLR to the 5’’ (125 mm) angle

grinder.

Principle of peeling and shaping tool D125

PLR cutting blades adjusting

must be on the same level. You can check it for example using small plywood piece

3 notches to the same level on the plywood!

max spindle speed

11 (most common in the USA)

,

grinder spindle thread in European and other metric system countries

. It is

recommended that the grinder be equipped with soft start system and electrical or mechanical

to the angle grinder

grinders disc

with diameter 22.23 mm / 7/8’’

is directed towards

Make sure the rubber seal

(O-ring) OR

before fixing the tool to the grinder’s spindle (figure 2,

2 mm, rubber mark NBR 70. This

seal prevents to avoid tool loosening after angle grinder motor is turnef off.

It works as a frictional

until there is no cap between tool body and disc

using special holes for that in tool body (figure 5). I

t is

important to use gloves, because there is a risk to injure operator’s hand against the cutting blades

,

from the power source when changing

cutting blades (figure

2) or when performing any general maintenance activities (such as adjusting or cleaning).

cleaning tool which includes

with the tool kit.

– therefore always

information is shown in figure 4

and figure 6.

- the thicker bark of log

mm), the wood surface finishing needs adjustment

Make sure that the cutting blades are equally adjusted (figure 3).

tool D125 PLR to the 5’’ (125 mm) angle

PLR cutting blades adjusting

– blades cutting edges

must be on the same level. You can check it for example using small plywood piece

- cutting edges must