GENERAL REQUIREMENTS AND RECOMMENDATIONS

1. Usable 9’’ (230mm) angle grinder’s rated power must be at least 2000 W (watts), optimal spindle

speed is 6000 min-1, max spindle speed 6600 min-1.

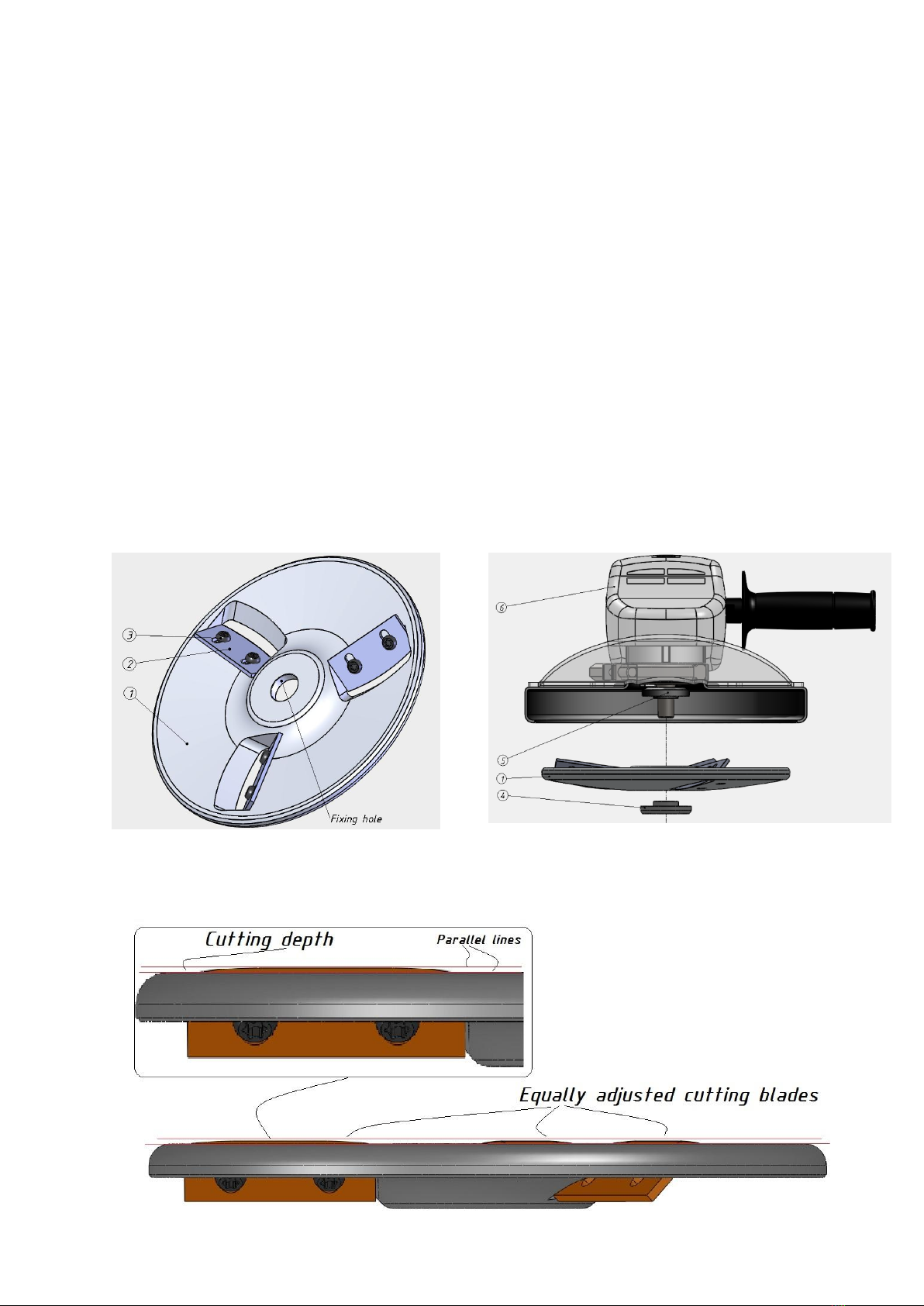

2. The log peeler disc (figure 1, pos. 1) must be fixed to the angle grinder with standard (22.23 mm,

7/8’’) disc flange (figure 2, pos. 5) and clamp nut M14 (figure 2, pos. 4). Ensure that the clamp

nut’s step edge is directed towards the tool’s fixing hole. Clamp nut must be tightened with a

special angle grinder’s wrench, but it is important to use gloves, because there is a risk to injure

operator’s hand against the cutting blades, when the wrench should be accidentally slipping

away. Please be very careful!

3. Always disconnect the tool from the power source when changing cutting blades (figure 1, pos, 2)

or when performing any general maintenance activities (such as adjusting or cleaning).

4. Handle cutting blades with care. After sharpening, the blades can injure hands –therefore always

use gloves! Sharpening information is shown in figure 4 and figure 5.

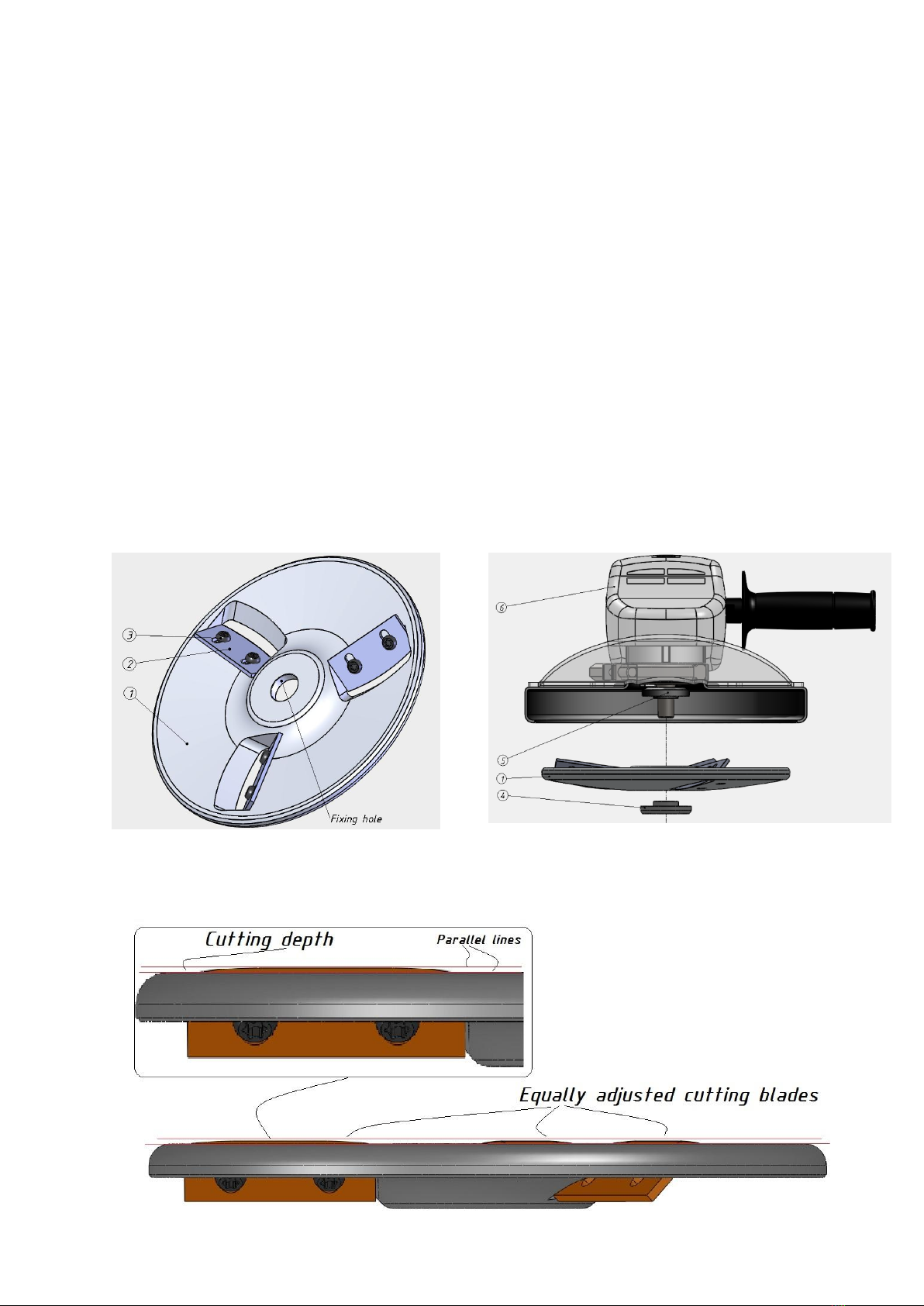

5. Cutting blades must be adjusted according to processing requirements - the thicker bark of log

requires to adjust larger cutting depth (up to 3.0 mm), the wood surface finishing needs

adjustment of blades to 0.5…1.0mm. Make sure that the cutting blades are equally adjusted

(figure 3).

6. Ensure that cutting depth and screws M6x12 ISO7380 (figure 1, pos. 3) are tighted. Screws must

be tightened up to the torque 9.0 Nm (79.7 In. Lb. or 6.64 Ft. Lb.). Please use ¼’’ Torx T30

screwdriver bit, which included to the set of log peeler tool.

7. It is not allowed to start the angle grinder with not correctly tightened cutting blades!

8. If there are some deviations from the normal product operation (strange noise, vibration, loose

cutting blade), you must stop the machine immediately!

Fig. 1 Complete log peeler tool

Fig. 2 Mounting sheme of log peeler tool D220

SPH / PLR to the 9’’ (230 mm) angle grinder

Fig. 3 Principle of peeler tool D220 PLR cutting blades adjusting. The same principle applies for model

D220 SPH