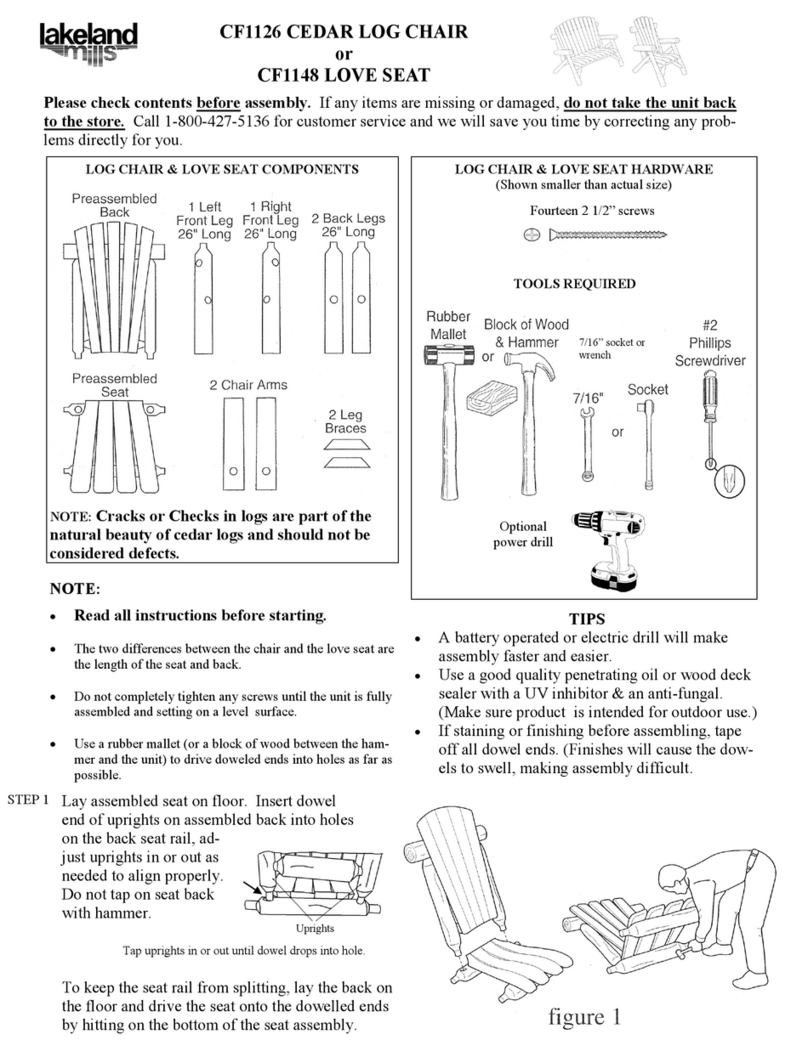

Lay assembled seat on a clean flat surface. Making sure the large

holes in the uprights of the assembled back are facing inward.

Insert the doweled end of the uprights of one of the assembled

seat backs into the holes on the back seat rail. (Adjust uprights in

or out as needed to align properly. See figure below). DO NOT

tap on seat back with hammer. To keep the SEAT RAIL from

splitting, lay the back on the ground and drive the seat on by hit-

ting on the bottom of the seat assembly. As shown in figure 2b.

Insert table supports into the holes on the front seat rail of the

assembled seat. Insert the doweled end of the rear table support

into the hole in the upright of the assembled back. Align the hole

in the upright of the remaining assembled back with the doweled

end of the rear table support and assemble as you did the first

assembled back. Align holes in the

table top with the doweled ends of

STEP 2

As shown in figure 3, insert 12” arm support into hole in arm,

then into hole in the top of the seat end. Drive the dowels in as

far as possible.

Fasten arm to frame from the back by tightening the preinstalled

lag screw into the pilot hole in the arm with a 7/16” wrench.

Repeat the process for the other arm.

STEP 3

Figure 2a

Figure 2b

Figure 4

Figure 3

Screw placement

Secure all dowel joints that you have assembled in place with

screws perpendicular to the doweled end as shown in figure 4.

Put barrel nut into side drilled hole in end of swing

bar. Position barrel nut with screwdriver and screw

in 5” eyebolt with 3/8” washer as shown in figure at

right. TIGHTEN DOWN SECURELY! Repeat

process for other swing bar.

Pre-measure and mark the arms for swing bars. Mark from the back of the

arms, 15” with pencil, as illustrated in figure 5. Fasten swing bars to side of

unit as shown. (This gives a suggested pitch of the seat. You may change the

pitch by altering the location of the lag screw in the arm.) With hammer tap a

5” lag screw through the bottom hole in swing bar and into pilot hole on seat

end. Tap a 5” lag screw through the upper hole in the swing bar and into the

arm about 1/2” deep at the place marked in pencil on the arm. Tighten down

lag screws.

STEP 4

STEP 5

STEP 6

Factory: 1 Lakeland Place, Edmore MI 48829, Phone: 800-427-5136, Fax: (989) 427-5824

www.lakelandmills.com

If you have hardware left over after completing your unit it most likely has

been assembled incorrectly and may not be safe to use. Please call customer

service at 1-800-427-5136, for assistance.

Check all nuts and bolts for tightness before and during each usage season.

Figure 5

Tap uprights in or out until dowel drops

into hole.

Uprights

Lakeland Mills recommends:

WeatherSeal Premium Oil-Based Exterior Wood Stain & Sealant

www.ContinentalProd.com

Look for videos on:

https://www.youtube.com/watch?v=LwdC2RBzv2U