5

Installation Operations and Maintanence

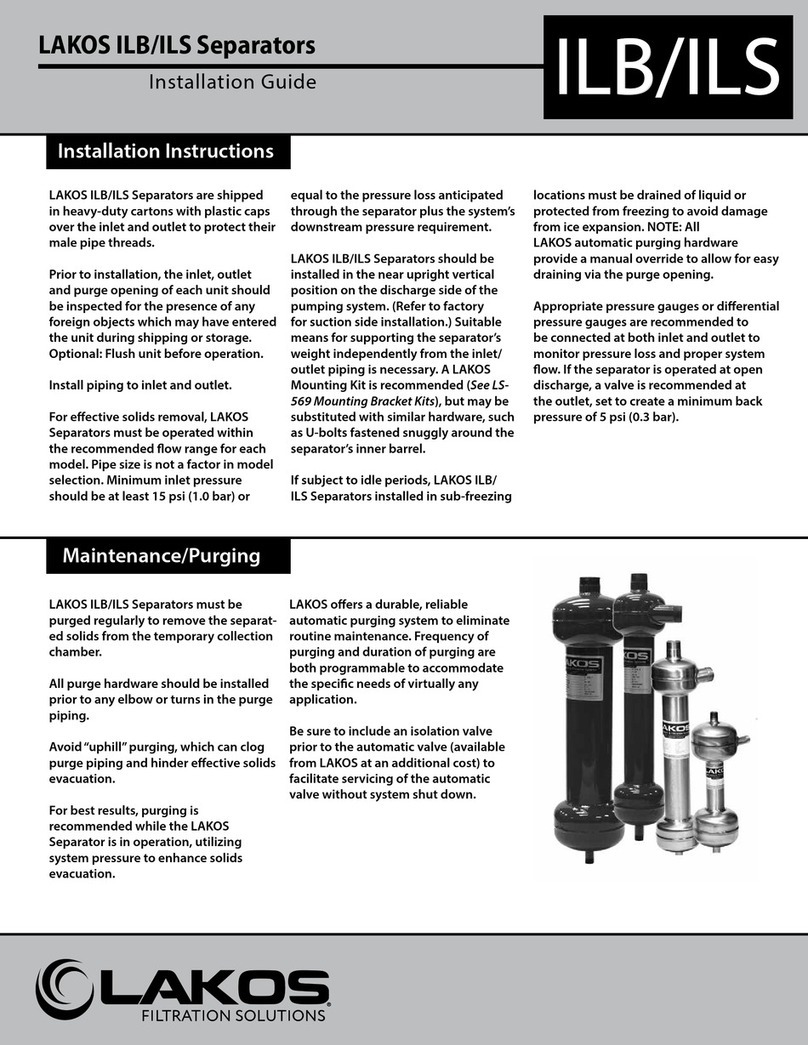

Maintenance/Purging

1. LAKOS Separators must be purged regularly. Otherwise, the accumulation of

separated solids will overll the separator’s collection chamber, substantially

aecting performance and causing undo wear.

2. Several purging options are available and all may be performed while the LAKOS

Separator is in full operation.

a. Manual: A full-port, straight-through valve may be installed on the standard

purge opening and actuated manually as necessary to purge separated solids.

b. Automatic: The use of LAKOS Separators in a given application typically

implies the need for heavy or unusual solids removal. A LAKOS Auto-Purge

System is therefore recommended. Consult your LAKOS representative for

details on motorized ball valves and other systems.

c. Semi-Automatic: The use of LAKOS Separators in a given application typically

implies the need for heavy or unusual solids removal. A LAKOS Solids Recovery Vessel

System is therefore recommended. The SRV-816 allows for continuous purging of the

solids collected into a separate collection bag. Once the bag is full with solids, the bag

is emptied. The bag can be cleaned and reused, or simply replaced. Consult your LAKOS

representative for details on the solids recovery vessel and accessories.

3. HTX/HTH Separators feature standard purge outlets. Prior to start-up, the installation

of a manual valve on the purge is recommended so that this outlet may be serviceable

at any time for either supplemental purging or as a stand-by, should the primary purge

line ever require servicing.

4. Important: All purge hardware should be installed prior to any elbows or turns in the

purge piping. Avoid “uphill” purging, which can clog piping and hinder eective

solids evacuation.

5. To determine the necessary frequency, purge often at rst and calculate the proper

rate with regard to the actual volume of separated solids. Purge duration should be

long enough to evacuate the purge chamber of solids. Frequency of purge should not

exceed the time it takes to over ll the collection chamber. Consult your LAKOS

representative for specic recommendations regarding your application.

6. When operating in sub-freezing temperatures, be sure to protect the separator’s

collection chamber and all purge line piping from freezing.