5

4 INSTALLATION

4-1 UNPACKING

All components of the stereo microscope are carefully packed, ensuring delivery in an

immaculate condition. We recommend to keep the packaging material, as it is used for

sending in the microscope or storing it for a longer period of time or transporting it to a

technical service team.

The MEZZO packaging contains the following components:

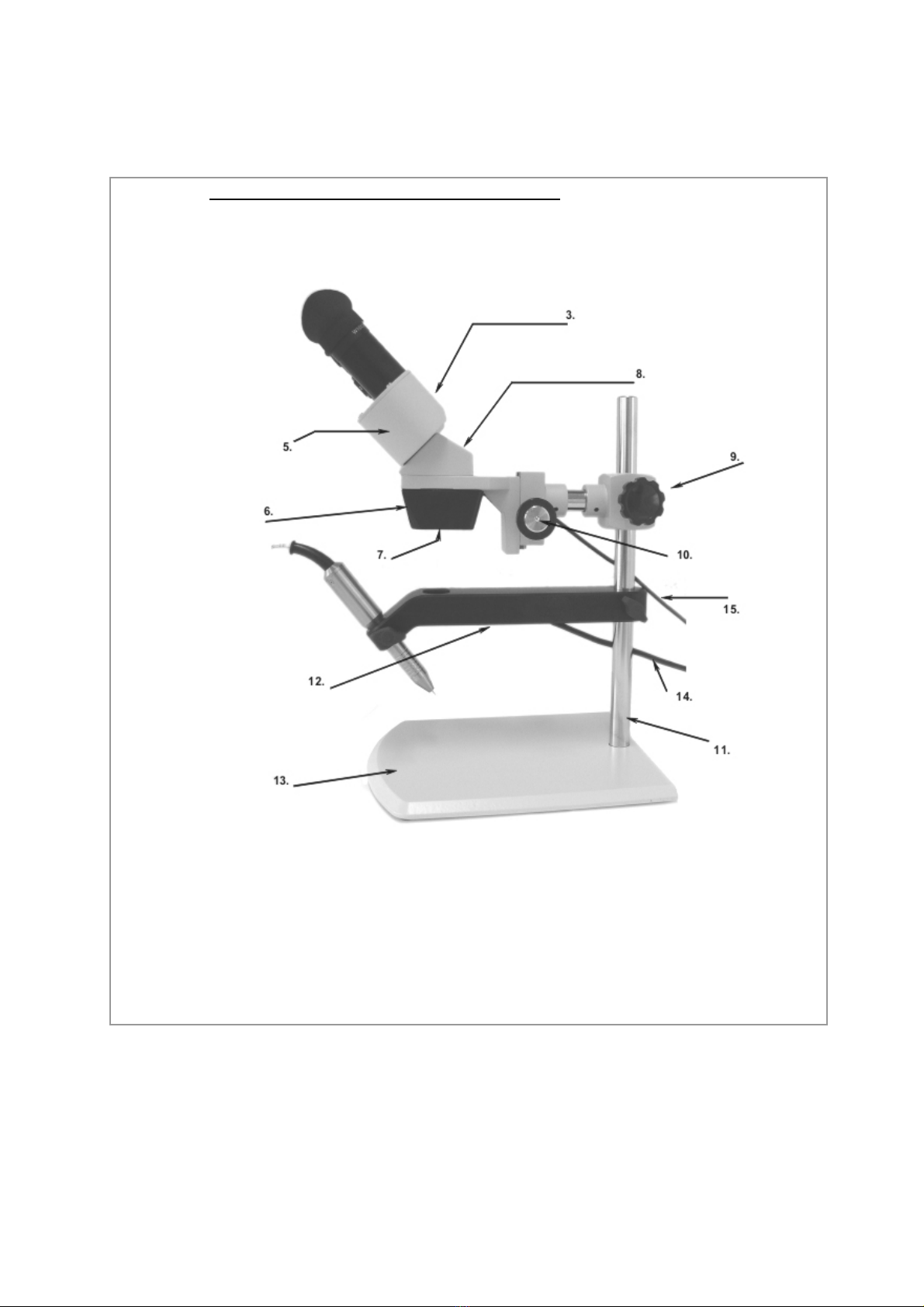

Microscope head with mount and LCD glare protection filter (4.2 Fig.1 - 10)

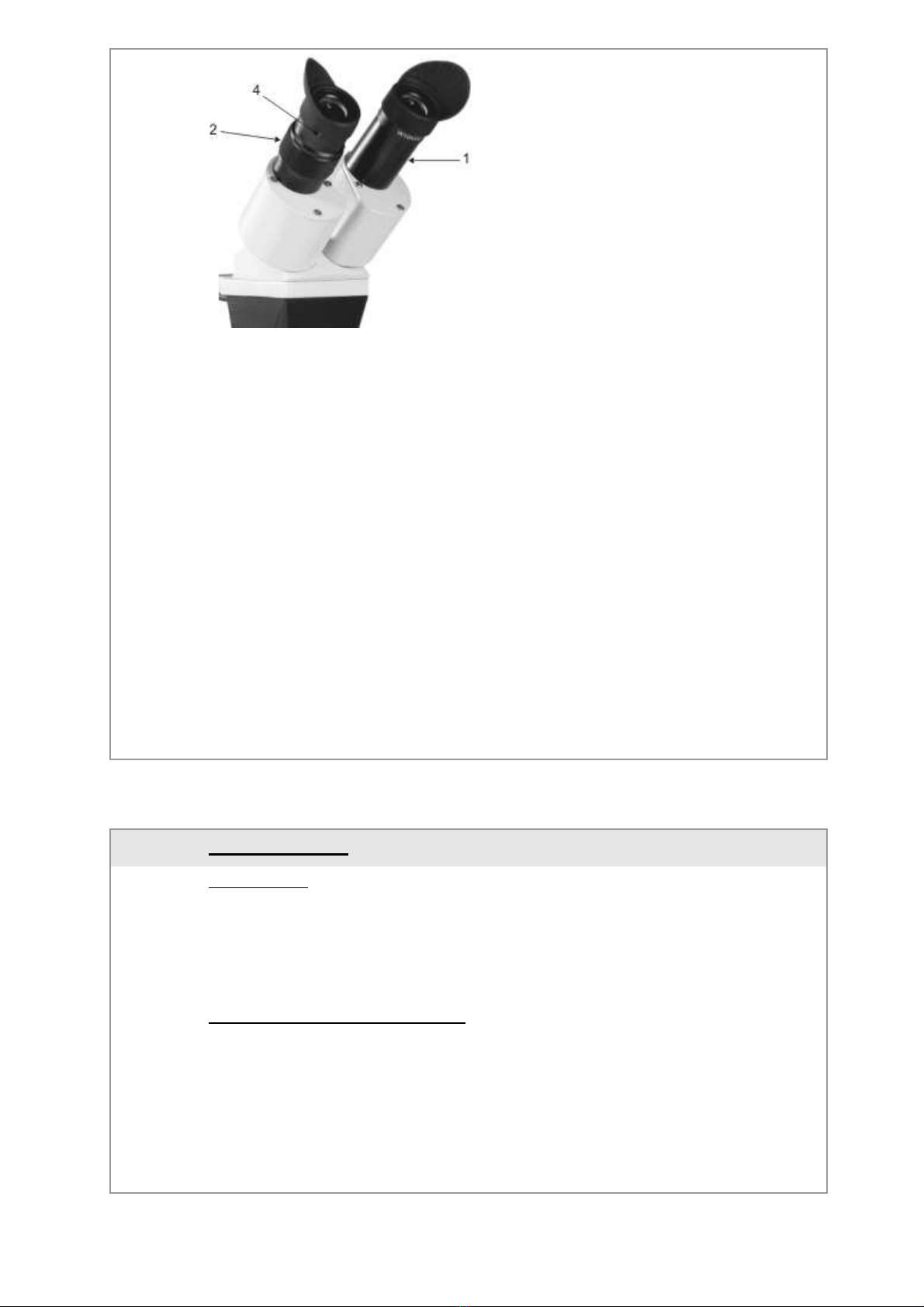

Two eyepieces with eyepiece covers (4.2 Fig. 2 - 1)

Supporting arm (for holding the welding hand-piece), with integrated LED light (4.2

Fig.12)

Bearing rod (4.2 Fig.1 -11)

Base plate, for attaching the bearing rod (4.2 Fig.1 -13)

Protective cover

Tools for adjusting the focussing levels

Remove and handle all microscope components with great care.

Avoid touching the lenses and optical elements. Also avoid contact with dust, water and

other polluting substances, as they soil or damage the lense surfaces and influence the

quality of the view.

ASSEMBLY AND START-UP

Please perform all work stages involved with the assembly of the stereo

microscope very carefully. The stereo microscope’s individual parts and elements

should not be assembled too forcefully.

Mount the bearing rod (11) to the base plate (13) with the attachment screw and place it

upright onto an even, safe and clean surface

Slide the supporting arm (12) over the bearing rod (11) and secure it slightly above the

middle of the rod, tightening hand tight.

Slide the microscope head (8) and its mount with retaining screw (9) over the bearing rod

(11), and secure it at about 5cm above the supporting arm for the hand-piece (12).

Insert eyepieces (1) and eyepiece covers and secure with locking screw (4)

Connect the control line (15) to the eye protection filter (shutter) (6) with the welding

device (note welding device instructions!)

Connect the LED light with the PUK 3s .

Insert the mains cable (16) into the connection socket marked “LED-Lamp 800 mA”, on

the back of the welding device.

Note!

Always test that the eye protection system (shutter) is in correct functioning order

before you start welding.

Through a press on the output power regulator of the welding device "PUK 3s",

you switch the eye protection filter from bright to dark.

If the eye protection filter (Shutter) does not switch from bright to dark, it must

immediately be replaced.