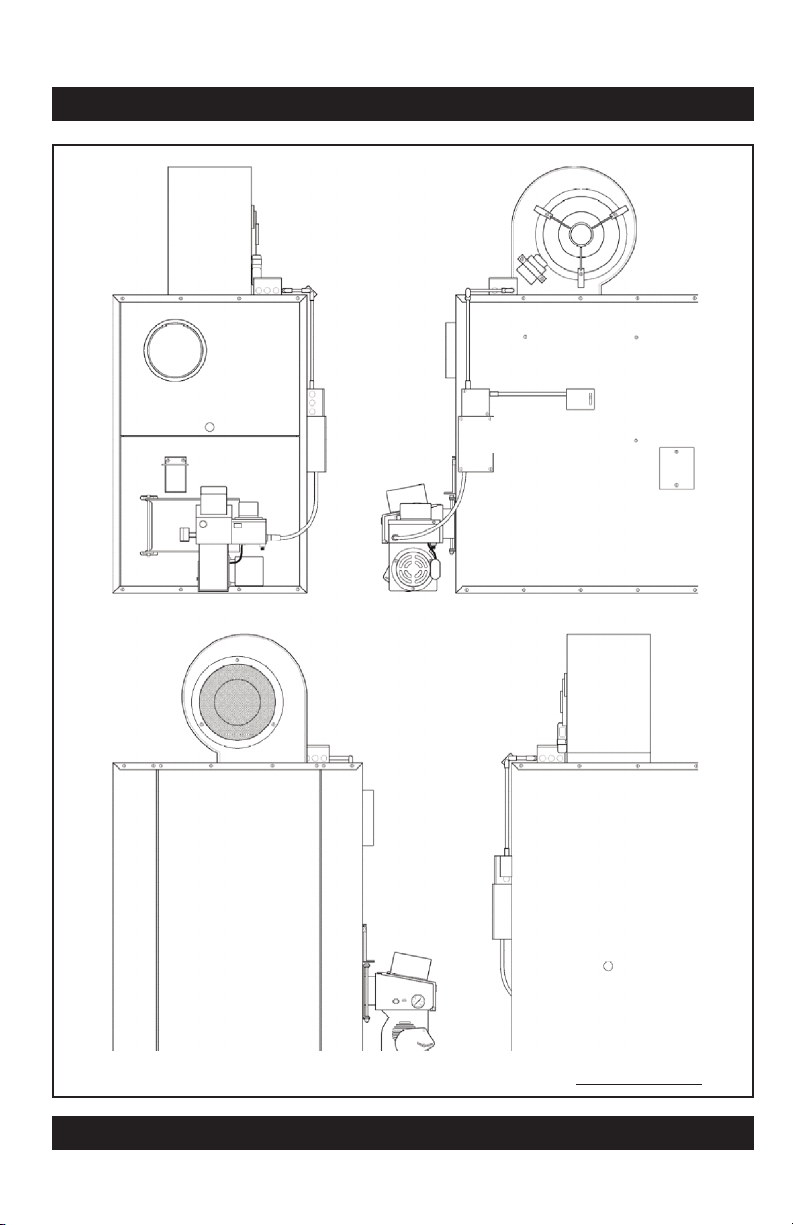

DHI-300 DUCTABLE WASTE OIL HEATER

Installationand OperatingInstructions

Tableof Contents:

Rules For Safe Installation and Operation ... .. ... ... ... .. ... ... ... .. ... ... .. page 2

Sec. 1 GeneralSpecificationsandHazards..........................................page 4

Sec. 2 HeaterInstallation..............................................................page 10

Sec. 3 Chimney/VentSystem ........................................................page 12

Sec. 4 Draft .............................................................................page 15

Sec. 5 Fuel Supply Tank /Piping Installation . . ... ... ... .. ... ... .. ... ... ... .. ... ... .. . page 15

Sec. 6 FuelSupplyPump/Piping .....................................................page 17

Sec. 7 CompressedAirInstallation ...................................................page 19

Sec. 8 lectrical Connections/Wiring Diagram . ... ... ... .. ... ... ... .. ... ... ... .. ... . page 20

Sec. 9 Controls .........................................................................page 23

Sec.10 PrimingFuelPump.............................................................page 25

Sec.11 BurnerStart-UpProcedure ....................................................page 27

Sec.12 FlameAdjustment .............................................................page 29

Sec.13 Maintenance Schedule / Service Adjustments . .. .. ... ... ... .. ... ... ... .. ... page 32

Sec.14 Troubleshooting................................................................page 44

Sec.15 WarrantyCertificate ............................................................page 50

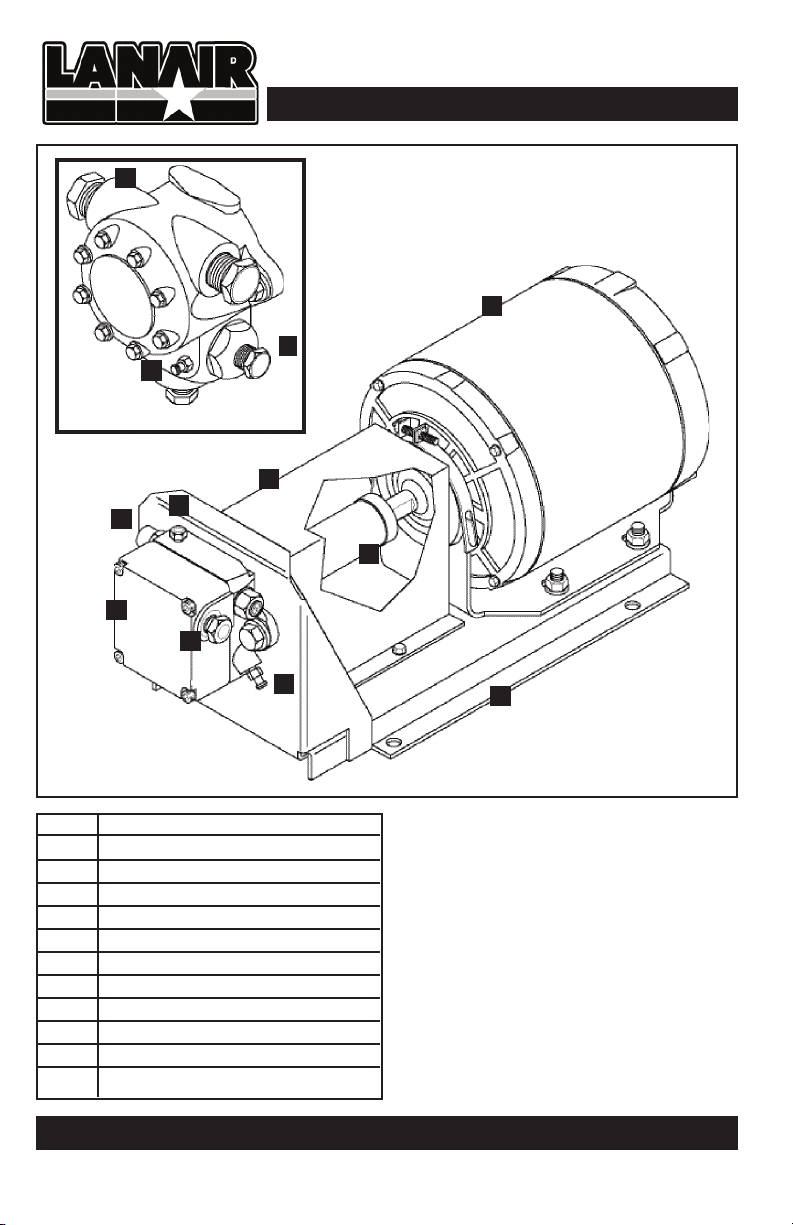

Sec.16 BurnerReferenceDiagram ....................................................page 51

Visit our website at: www.lanair.com

3

Section 15 - Warranty

QUESTIONS?... Contact Customer Service at 1-800-753-1601 -F 8:00 am- 4:15 pm CST

50

Items Not Covered Under Warranty

Conditions That Will Void Warranty

LANAIR 1O YEAR WASTE OIL HEATER

LIMITED WARRANTY

Lenan Corp., MAN FACT RER, hereby warrants that any part of manufacturer’s product shall be free from defect in

material and workmanship under normal use according to the provisions and limitations herein set forth for a period of

one (1)year provided same is returned (pre-paid) F.O.B. Janesville, Wisc. for inspection and warranty determination.

MAN FACT RER warrants the heat exchanger/combustion chamber for three (3) years from the date of purchase and

pro rata thereafter according to the following schedule: If a defect occurs during the first three years,

MAN FACT RER will repair or replace the combustion chamber/heat exchanger FREE* of charge. If a defect occurs

in years four through ten (4-10) MAN FACT RER will repair or replace your combustion chamber/heat exchanger.

Your guaranteed replacement cost will be shared by MAN FACT RER 50/50.

IMPORTANT: Combustion chamber / heat exchanger must be maintained in accordance with the installation / operat-

ing instructions. This extended warranty does not cover normal wear items such as gasket material, chamber inserts,

nuts, bolts, labor costs, etc. The warranty card must be returned within ten (10) days of purchase date in order for this

warranty to be valid. Warranty is limited to original purchaser

*MAN FACT RER’S determination regarding repair or replacement is final.

Cost of freight is owner’s responsibility.

Model Number DHI Series Heater Date Purchased:

• Any portion of the combustion chamber / heat exchanger if:

- The unit is not installed per the owners manual.

- The yearly inspection requirements are not current.

- If the heater is used for a purpose for which it is not intended.

- If the heater is not operated in accordance with the printed instructions in the

- If any alterations or unauthorized repairs are made to the unit.

• Damage incurred from overfiring, abuse, neglect, shipping, natural acts, misuse or accident.

• Labor costs for service calls for any reason including:

- Cleaning or performing required maintenance.

- Installation corrections

- Any parts installation.

• Parts that are replaced because of normal wear and tear.

• Goods purchased under this agreement shall be used exclusively by the buyer and no

other person or third party shall benefit from the express or implied warranties contained

in the agreement.

• Use of liquids such as: solvents, brake fluid, gasoline, K-1, kerosene, paint thinners, gear lube, trans-

former oil, cutting oils, anti-freeze, water or any other liquid not approved for use.

• Tampering with internal components

• Failure to inspect and clean combustion chamber/heat exchanger at the end of each heating season.

• Continuous over-firing of the unit

• Heater has not been installed or serviced in accordance to the installation / operating manual.

• Alteration or misuse of any part

• Use of parts other than those supplied by Lanair.

NOTE: Lenan Corporation may require photographs of the heater installation for warranty

determination