3

INSTALLATION

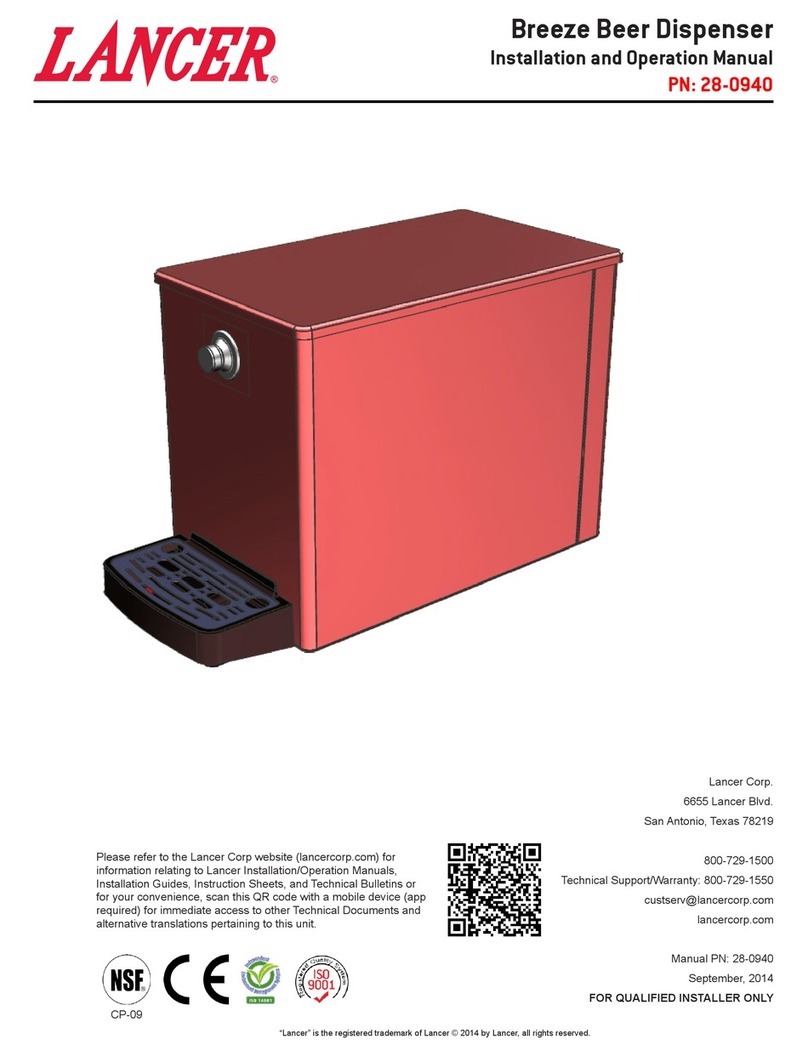

Unpacking the Dispenser

1. Cut steel band and remove.

2. Remove plywood shipping base from unit.

3. If leg kit has been provided, assemble legs by tilting unit.

Selecting/Preparing Counter Location

DO NOT LAY UNIT ON ITS SIDE OR BACK

! ATTENTION

Inspect unit for concealed damage. If evident, notify

deliveringcarrierandleaclaimagainstthesame.

NOTE

The drain spider is located to the left side near the front

of the bin. The coldplate has a cavity designed to hold

the drain spider. During shipment or installation, the

drain spider may become dislodged from its original

position.Prior to installing the dispenser, ensure the

drain spider is in the correct position.This will prevent

drain clog issues. Inspect the lower bin area to ensure

the drain spider is secure in the coldplate cutout. If the

drain spider is not in place, locate the drain spider and

reinstall in the cold plate cavity where drain line exists.

Drain Spider

In order to facilitate proper dispenser drainage, ensure

that the dispenser is level, front to back and side to

side. Place a level on the top of the rear edge of the

dispenser. The bubble must settle between the level

lines. Repeat this procedure for the remaining three

sides. Level unit if necessary. For optimum

performance place the unit at a 0° tilt.

Leveling the Dispenser

If unit is to be transported, it is advisable to leave the

unit secured to the plywood shipping base.

NOTE

1. Connecting lines can be run through the front of the unit and

can extend down through a counter cutout.

2. Select a level, well ventilated, accessible location away from

direct sunlight (avoid) or overhead lighting.

3. The selected location should be able to support the weight of

the unit with the ice after counter cut out is made.

The dispenser should only be installed in a location

where it can be overseen by trained personnel

NOTE

NSF listed units must be sealed to the counter or have

four (4) inch legs installed.

NOTE

Dispenser Installation

1. Remove Top Cover.

2. Connect Product supply line to 3/8 inch barb tting located at

the front of the unit.

3. Connect other end of Product supply line to keg coupler

using 3/8 inch barb tting

4. Attach keg coupler on to the keg by turing clockwise until it

stops. Check for leaks.

5. Install the ice bin drain hose; connect the 90° elbow or

straight tting underneath the unit’s base. The ice bin drain

is located towards the front of the bin and slightly to the left.

Connect the hose. Extend the hose to an open type drain.

Drain line must be insulated with a closed cell

insulation. Insulation must cover the entire length of

thedrainhose,includingttings.Thedrainshouldbe

installed in such a manner that water does not collect

in sags or other low points, as condensation will form.

! CAUTION

The ice used in this unit may NOT be potable and

should not be ingested. DO NOT eat, chew, such,

swallow, or put into any drinks. The ice used in this

unit is intended solely for the refrigeration purposes

of the product.

! CAUTION

Pouring hot water down the drain may cause the Drain

Tube to collapse. Allow only luke warm or cold water to

enter the Drain Tube. Pouringcoee,tea,orother

similar substances down the drain may cause the Drain

Tube to become clogged.

! ATTENTION

6. Fill unit with ice and Install Top Cover and Drip Tray.