E6

Battery Charging and Monitoring

1. Battery must be fully charged before first use.

2. Plug the charger into a 110-240AC outlet.

3. Always charge the battery at room temperature. If the battery is used in a cold environment,

allow it to warm up for at least an hour before charging. Cold batteries will not be charged

completely and battery components may be damaged.

4. Only charge battery in well ventilated area away from flammable materials such as cloth or

carpeting.

5. During the charging phase, the light on the charger is red. When the battery is completely

charged, the light will turn to green.

6. To disconnect charger, remove the three-pronged plug from outlet, then disconnect the

charger from the battery.

7. DO NOT leave the charger being connected to the battery for more than 24 hours.

8. The battery status indicator is mounted on the top of the battery to allow you to observe the

level of the battery power while in use. When all the 3 green lights and 1 red light are lit, it

means the power is sufficient. When only the red light is lit, it means it needs to be charged

immediately.To check the charge level, simply pressthe indicator button.The lights on the

status indicator show the charge level of the battery.

9. When battery power becomes insufficient to drill through ice, turn off the power switch,

disconnect the battery from power head, and re-charge the battery. Do not further discharge

the battery beyond the point it cannot power the auger through the ice. Completely draining

the battery may damage the battery components and increase the likelihood of battery

malfunction, battery fire, or even explosion.

10. If battery becomes warm or hot during charging procedure, disconnect it from charger.

Allow battery to return to room temperature, and attempt to charge again. If this persists a

second time, disconnect battery from charger and contact customer service

Notes:

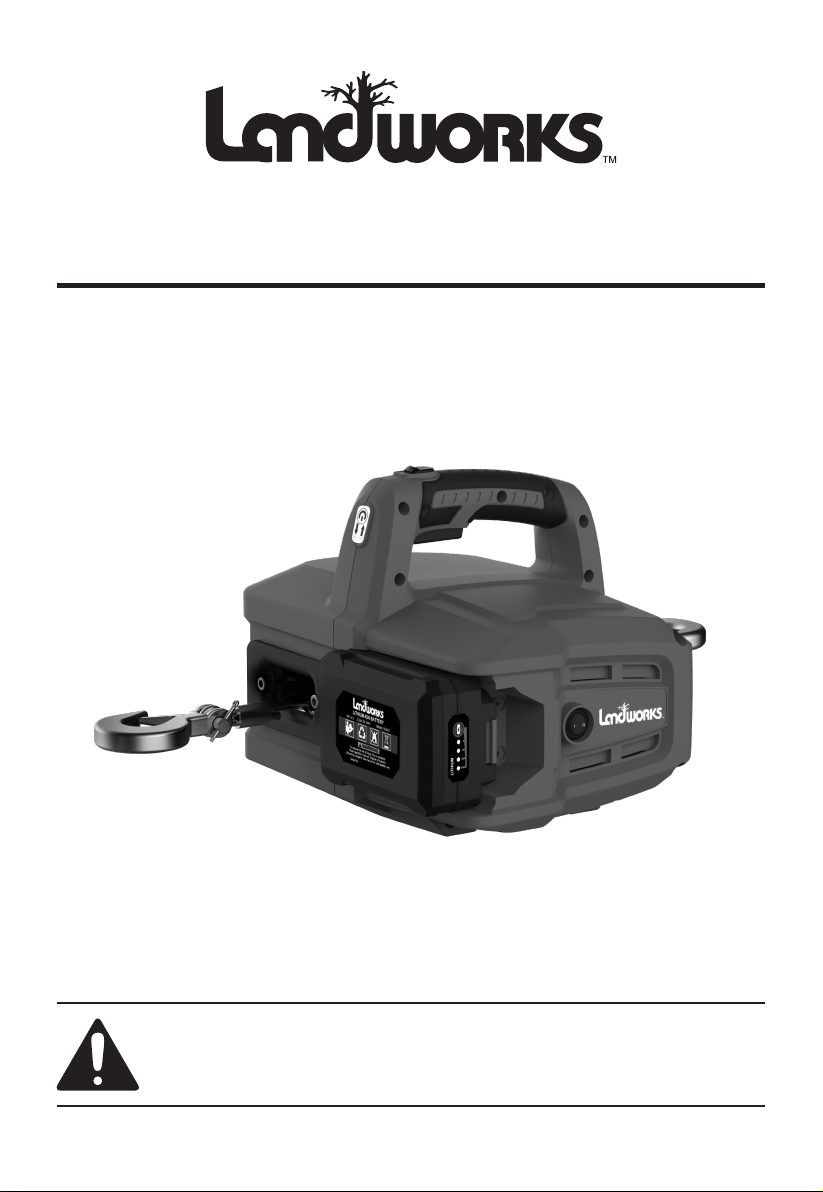

The traction tool has power switch and steering switch trigger controller control.

The steering switch provides control of the forward and reverse rotation of the winding.

Maintaining the tension of the rope when going up or down, need to winding in order, there by

damaging the rope and traction tools. When you see the red paint on the wire rope or the black

sheath on the polyethylene rope, the warning rope is close to the critical position. Do not pull

the rope further in the original direction. Otherwise, the rope will be wrapped around the drum

in the wrong direction, which may damage the rope and the guide rail device. Choose the

direction switch to make sure that the arrow above the light is always aligned with the actual

direction of the incoming and outgoing rope.

Overload protection

Exceeding traction load will lead to controller protection, thus interrupting the power supply of

the motor. This prevents overheating and potential motor damage. Whenload-exceeding

controller trips, do not attempt to impose the same load. The weight of the load should be

reduced and the traction tool can be restarted after power failure.

MAINTENANCE

Please check whether the wire rope and hook have signs of wear or damage before and after

each operation. Wear and damaged parts must be replaced. Do not attempt to pulling out or

repair damaged ropes.

Keep wire ropes and hooks free from contamination and use clean towels to remove dirt and

debris. Usage of grease on wire ropes and hooks can prevent corrosion. Always keep the

electrical terminals on the battery pack clean and make sure that the battery is not broken or

damaged.

If there are twists, incisions, worn parts and broken strands in the traction rope, please stop

using them.