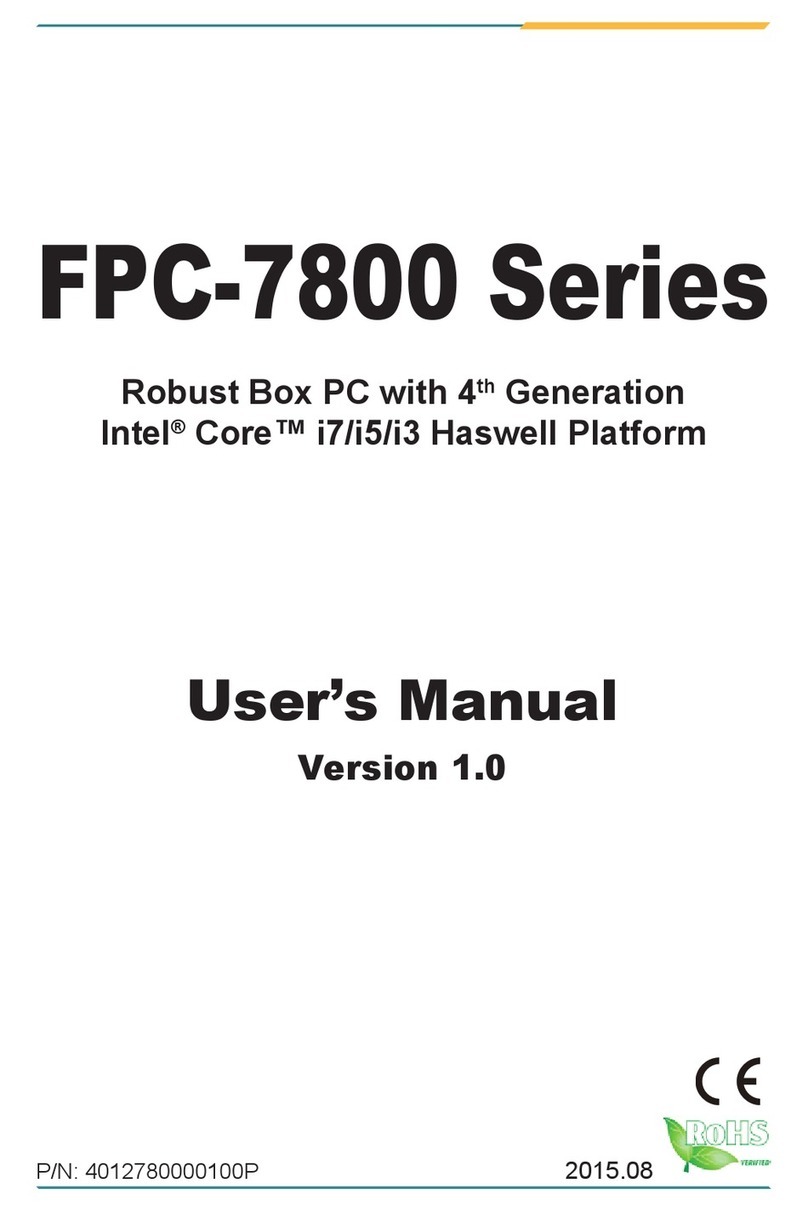

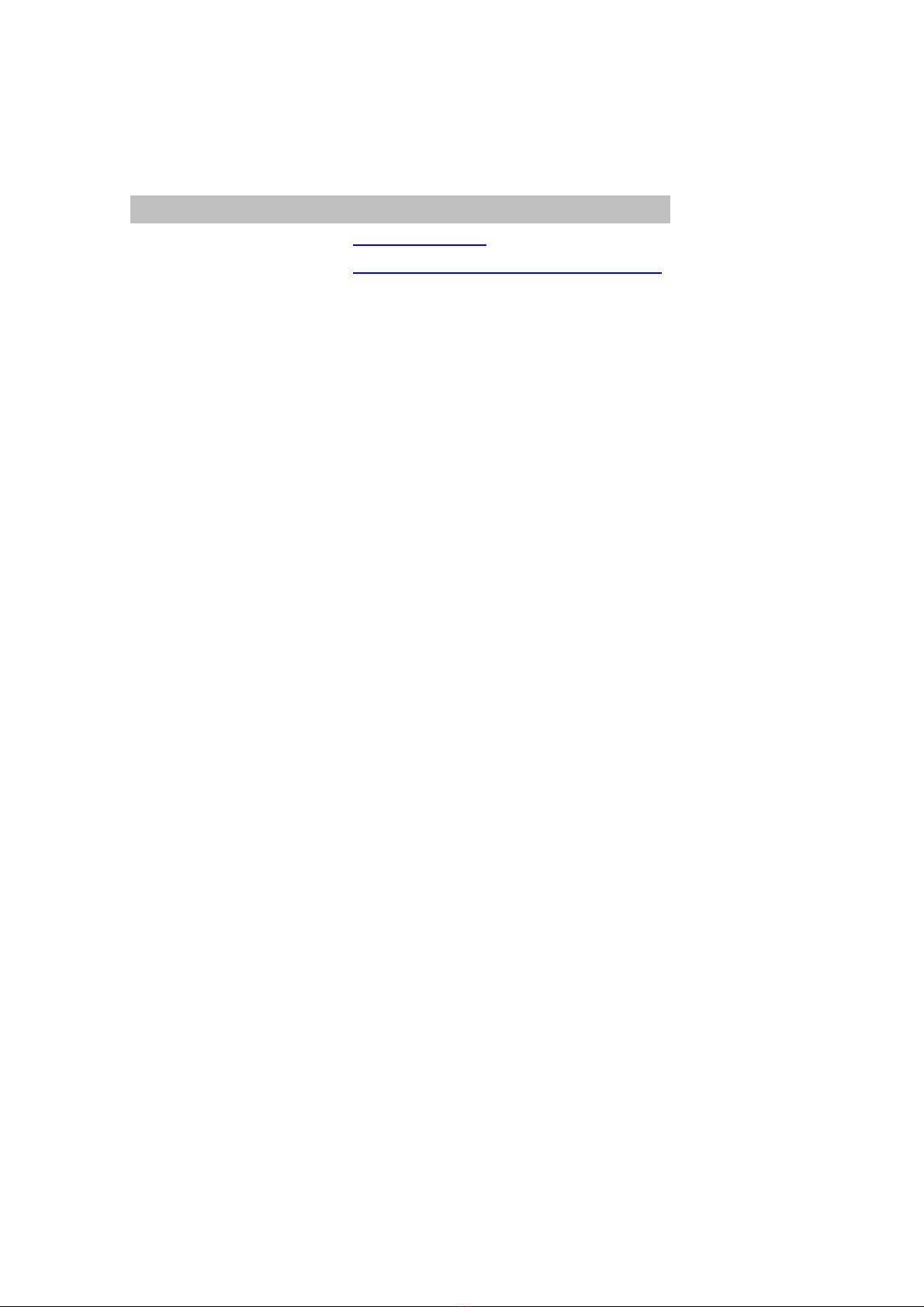

Table of Contents

Revision History ............................................................................................................2

Chapter 1: Introduction................................................................................................10

System Specification............................................................................................10

Ordering Information...........................................................................................11

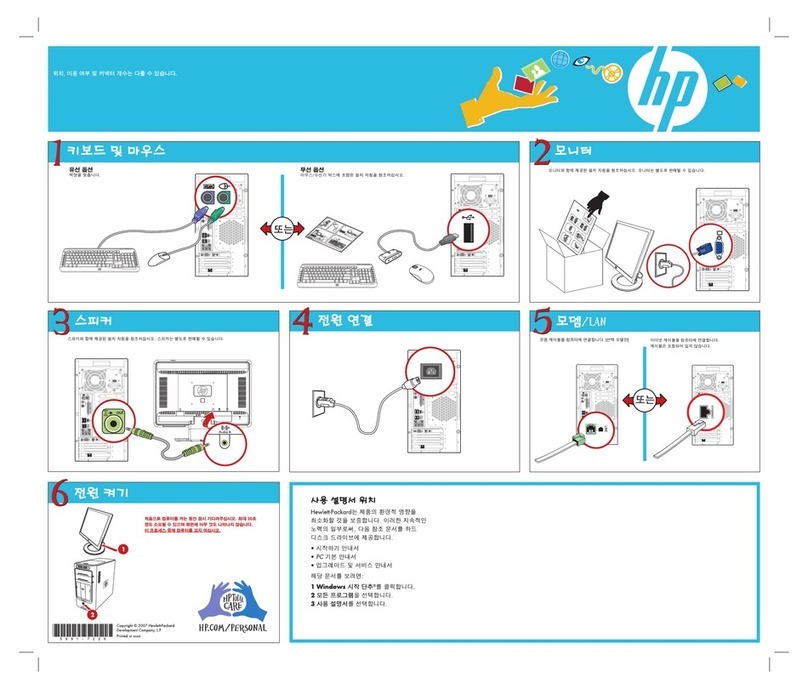

Package Contents.................................................................................................12

Chapter 2: System Overview.......................................................................................13

Mechanical Drawing............................................................................................13

Block Diagram.....................................................................................................14

Front I/Os.............................................................................................................15

Rear I/Os..............................................................................................................16

Chapter 3: Board Layout..............................................................................................17

Jumpers and Connectors on the Motherboard .....................................................17

Jumper Setting and Connector Pin-out................................................................18

Chapter 4: Hardware Setup..........................................................................................26

Installing the System Memory.............................................................................27

Installing mSATA and Mini-PCIe Modules.........................................................28

Chapter 5: BIOS Setup.................................................................................................29

Main.......................................................................................................................30

Advanced ................................................................................................................31

PXE Function...............................................................................................31

W836270HG Super IO Configuration.........................................................32

Serial Port 1/2 Configuration.......................................................................33

W836270HG HW Monitor..........................................................................36

Serial Port Console Redirection...................................................................37

COM Console Redirection Settings.............................................................37

Generation 2 LAN Bypass Configurations..................................................44

Trusted Computing ......................................................................................46

USB Configuration ......................................................................................48

IntelRCSetup........................................................................................................52

Processor Configuration...............................................................................52

North Bridge Chipset Configuration............................................................54

South Bridge Chipset Configuration............................................................55

SATA Configuration....................................................................................56

Security ..................................................................................................................61

Boot.......................................................................................................................62

Save & Exit ..............................................................................................................63

Appendix A: Programming Watchdog Timer ..............................................................64