Larson Electronics, LLC Phone: (800) 369-6671 Fax: (903) 498-3364 www.larsonelectronics.com

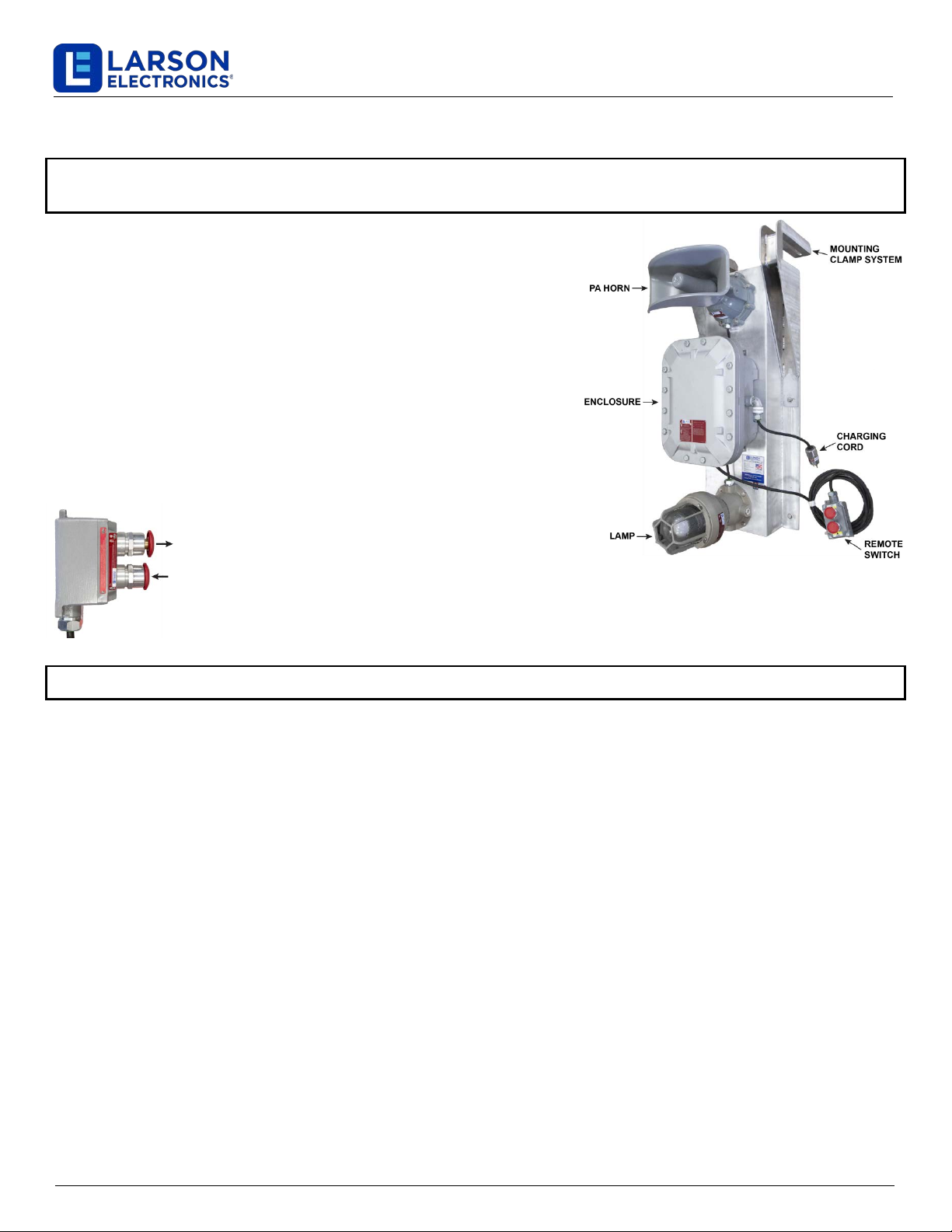

If the enclosure must be opened for servicing, to check or replace internal devices and

apparatus, the following procedures should be followed.

WARNING: Before servicing the fixture, be certain the electrical power is OFF and

remove the unit is removed from the Hazardous Environment. This fixture contains

an “Internal Voltage Source” and remains energized when disconnected from direct

line power sources.

•Remove all cover bolts. Clean and inspect. Replace any corroded, bent or otherwise

damaged bolts with new, factory authorized bolts obtained from an authorized

distributor.

•Open enclosure. Do not use hammer, screwdriver, or any prying tool to open cover,

except as shown in Figure 4.

•Inspect cover hinges. If hinges are damaged or do not function properly, contact a factory authorized service

representative for hinge replacement and installation.

•Inspect machined flange (flame path) surfaces. Surfaces must be smooth, free of nicks, scratches, dirt or any

foreign particle build-up that would prevent a proper seal. Should surface be damaged contact factory. Never

attempt to rework surfaces by sanding, grinding, ect. Surfaces must seat fully against each other to provide proper

explosion-proof joint.

•Inspect water exclusion gasket. If gasket is damaged, do not attempt field replacement or repair.

•Contact a factory authorized representative for a replacement cover. When removing gasketed cover for

replacement, do not detach hinge body from cover.

•Remove cover and hinge body from enclosure by removing the hinge pins. (see figure

5) The damaged gasket can be removed from the cover and the cover without gasket can be

safely used in Class I & II hazardous (classified) locations, however the enclosure may not be

raintight or hosedown tight.

•Clean flange surface by wiping with a clean, lint-free cloth. Apply a light coating of

lubricant to flange surfaces and close cover. Install and tighten all cover bolts to 30 ft. lbs. Make

certain no cover bolts are omitted. Use only factory authorized bolts. Check the flame joint with

a .0015” feeler gauge. The gauge must not enter the flame joint more that 1/8” at any point.

Missing bolts or an improper flame joint can result in an explosion, creating a potential for

physical injury and property damage.

LAMP REPLACEMENT

•Turn OFF the supplying circuit before opening fixture for re-lamping. To re-lamp loosen the locking screw and

remove the globe support assembly.

•The globe support assembly disengages after approximately 3 turns. *Replace the lamp with one of the correct

size and type. Refer to the fixture nameplate for this information. When relamping, be careful not to damage the

threaded areas of the fixture, as they maintain the fixture’s explosion proof properties. Clean the threads and

apply a thin coating of lubricant before reassembling.

•To maintain maximum light output, the fixture should be cleaned periodically. Maintenance procedures sometimes

require fixtures to be hosed down for good housekeeping.

•The supply circuit must be turned OFF and the fixture globe must be allowed to cool to the ambient room

temperature before cleaning. Only mild, non-abrasive cleaning agents should be used. These periodic cleaning

procedures are important to prevent the accumulation of dust and dirt which will impair the light output of the

fixture. The glass globe should be regularly inspected for scratches and chips and, if damaged, the entire globe

support assembly must be replaced.

THESE INSTRUCTIONS MAY NOT COVER ALL DETAILS OR VARIATIONS OF THIS PRODUCT FOR YOUR EQUIPMENT OR INSTALLATION REQUIREMENTS. SHOULD FURTHER

INFORMATION NOT COVERED BY THESE INSTRUCTIONS BE REQUIRED, PLEASE CONTACT LARSON ELECTRONICS BY EMAIL AT SALES@LARSONELECTRONICS.COM OR BY PHONE AT

1-800-369-6671 FOR FURTHER ASSISTANCE.

PLEASE VISIT LARSONELECTRONICS.COM FOR WARRANTY AND RETURN INFORMATION.