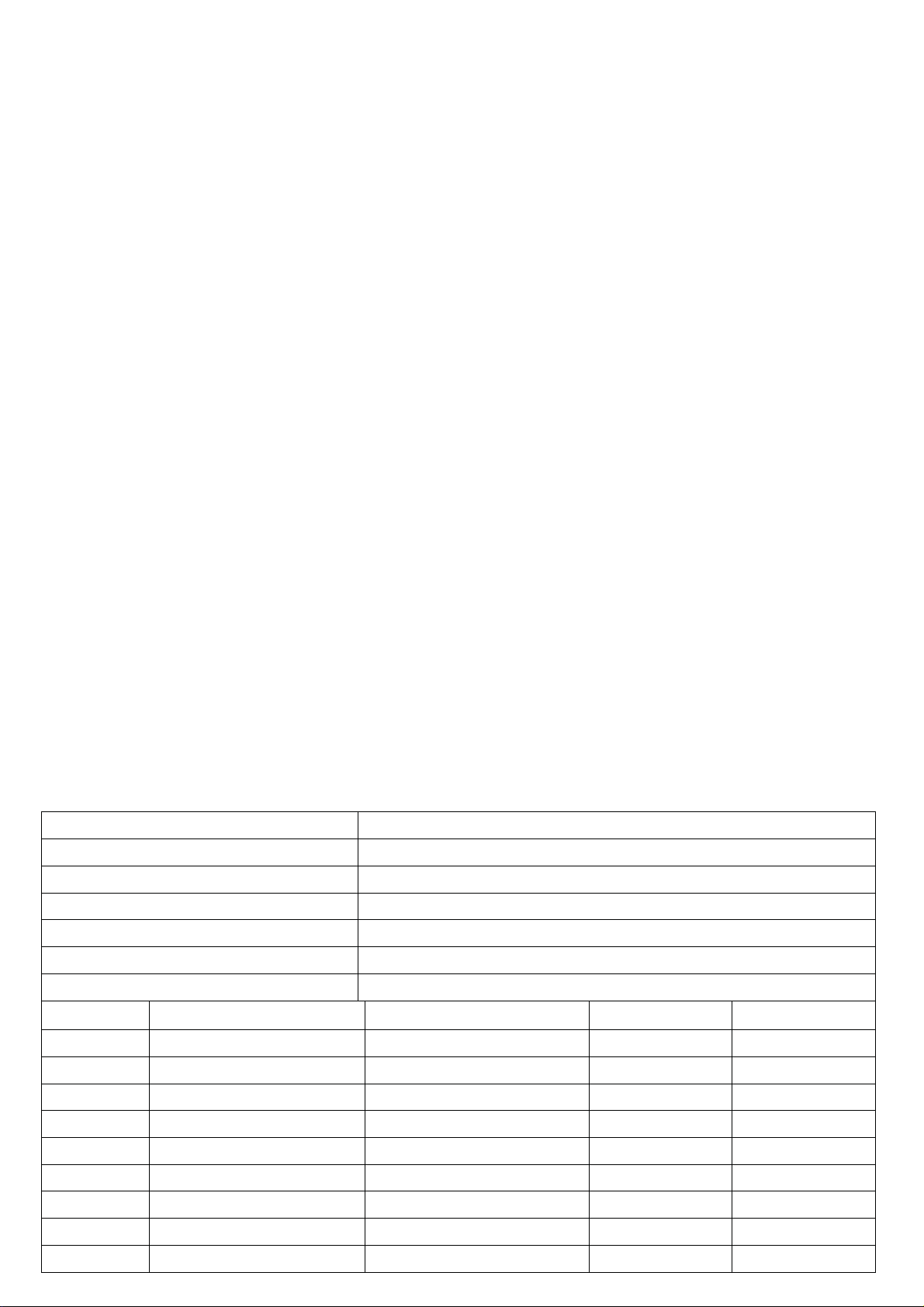

TEMPLINK 3000 INSPECTION RECORD –every six months

ID NUMBER (See stainless steel ring):

Date of manufacture:

Remove from service date:

Date of purchase:

User name:

Company name:

Company phone number:

Date of

Inspection Defects found at time of inspection Action Taken Signature of Inspector Next inspection due

MAINTENANCE – PERIODIC & BEFORE EACH USE

All items of safety equipment which are in use shall be subjected to periodic inspection and servicing.

These regular scheduled inspections and servicing must be carried out by a competent person.

Procedures to be carried out before each use:

Feel and visually inspect anchors in the following ways for signs of deterioration.

- Inspect the cable for:

a) Cuts, distortion, excessive stretching.

b) Damage due to contact with chemicals, heat, corrosives or solvents.

c) Deterioration due to moisture, mildew or ultraviolet exposure.

d) Abrasions and excessive wear, especially where contact with hardware has occurred.

e) Discolouration from exposure to chemicals or prolonged exposure to ultraviolet light.

f) Rigidity resulting from overloading or the TempLink sustaining a fall.

- Inspect the tabs for:

a) Distortion as a result of a fall.

b) Missing tab, excessive wear, burring of the tabs.

c) Distortion around the tab which could indicate the TempLink has sustained a fall.

d) Free from dirt or other obstructions.

- Inspect the cable and tabs joining position for signs of wear.

- Inspect the “remove from service” date on product, the shelf life of this product does not exceed 10 years.

- The TEMPLINK 3000 anchor point has one energy absorbing stainless steel component. If this energy absorbing region is

expanded/distorted this will indicate the anchor point has arrested a fall and should be removed from service.

- Inspect the components of the anchor for corrosion, superficial surface marking is permitted while deeper corrosion or pitting

will require attention.

- Consult TempLink 3000 user/s for any additional situations that may have caused damage to the TempLink 3000.

- If the TempLink 3000 has sustained any of the above issues or any doubt exists remove the TempLink 3000 from service.

Cleaning Instructions:

If you do need to clean the TempLink 3000 use only warm water and no soap/detergent products. Thoroughly dry before storage.

Care/Maintenance:

Ensure the TempLink 3000 is stored in the following manner, away from direct UV/sunlight, in a dry environment, away from

exposure from chemicals, heat, corrosives or solvents.

Regular inspection and care of your equipment is of the utmost importance. SafetyLink recommends the TempLink 3000 should

be removed from service and destroyed after 5 years from the date of first use. The product has a shelf life of 10 years from the

date of manufacture.

THE TEMPLINK 3000 MUST BE INSPECTED EVERYTIME BEFORE USE, SIX MONTHLY LOGGED SAFETY INSPECTIONS

ARE TO BE COMPLETED BYA COMPETENT PERSON.