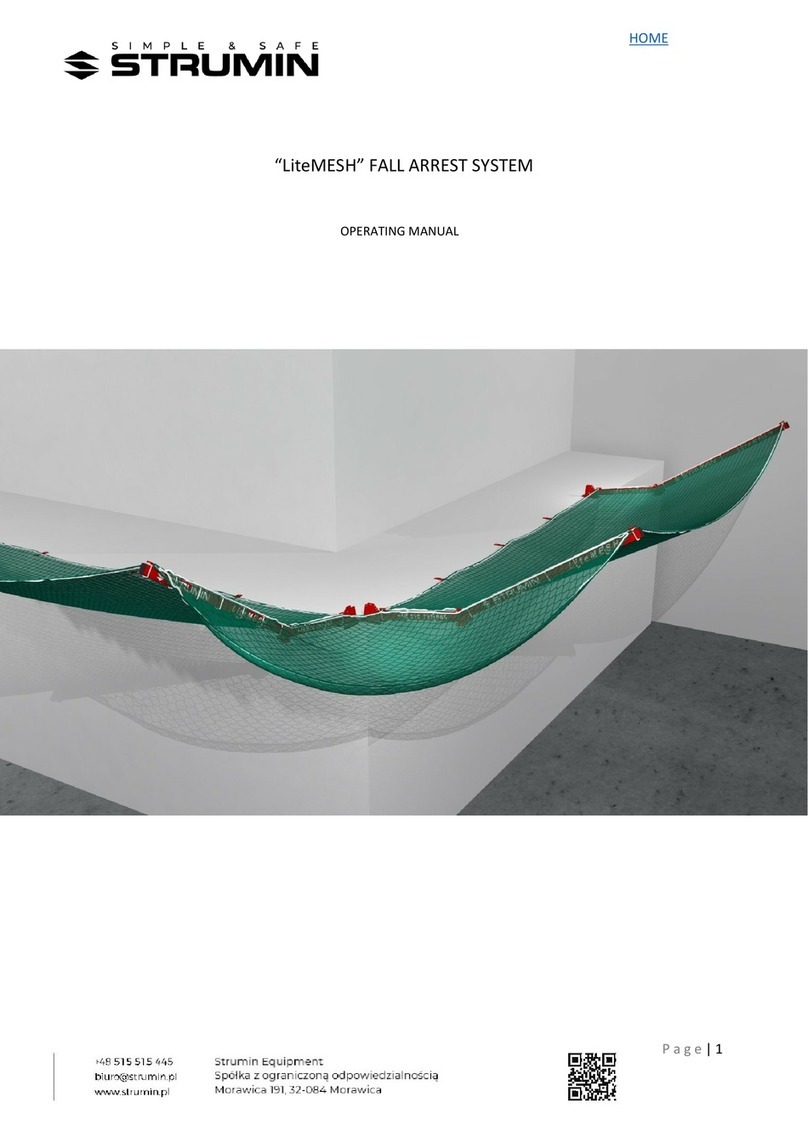

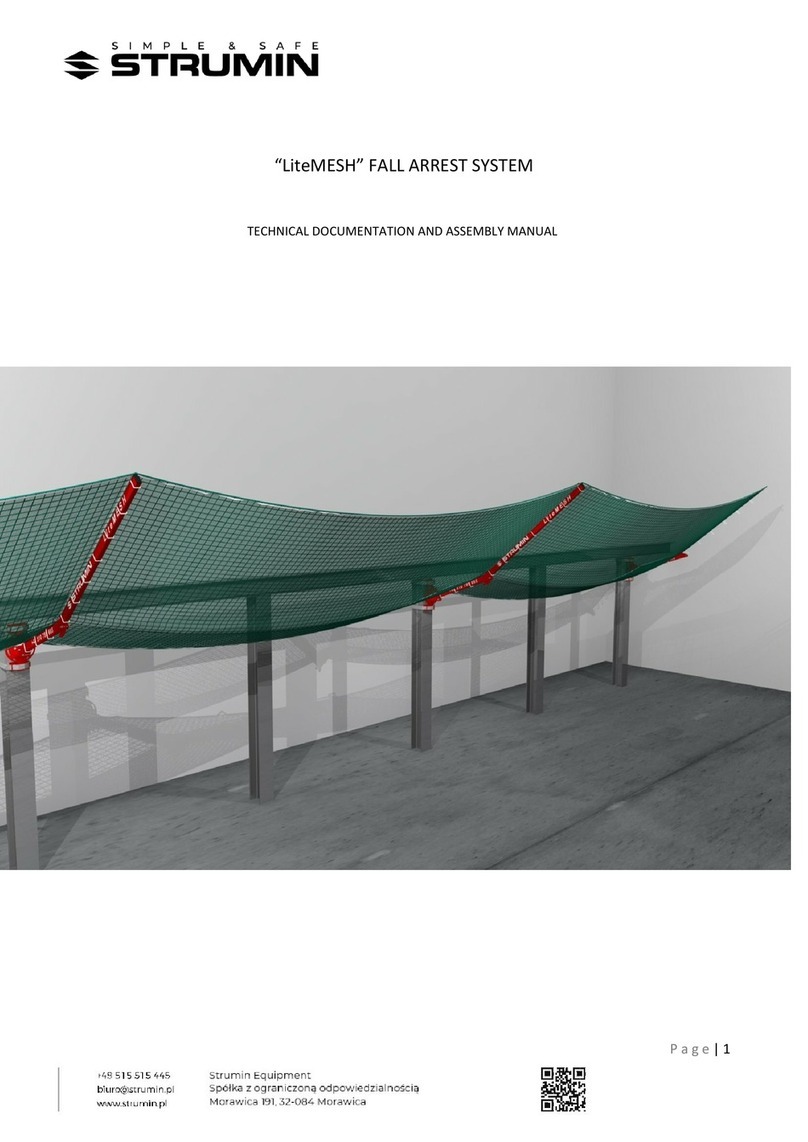

STRUMIN SYSTEMIC EDGE PROTECTION User manual

P a g e | 1

SYSTEMIC EDGE PROTECTION

SAFE WORK AT HEIGHTS

P a g e | 2

ATTENTION !

TECHNICAL DOCUMENTATION

BEFORE EVERY USE OF THE EDGE PROTECTION SYSTEM, THE USER SHALL READ THIS TECHNICAL

DOCUMENTATION AND ALWAYS STRICTLY FOLLOW THE RULES DESCRIBED HEREIN. THESE INSTRUCTIONS

WERE PREPARED FOR ALL WORKERS AND PEOPLE THAT WILL WORK ON TRANSPORTING, UNLOADING,

ASSEMBLING, DISASSEMBLING, STORING, CHECKING AND ANY OTHER WORKS CONNECTED TO THE DEVICE.

EVERY USER IS OBLIGED TO READ AND GET FAMILIAR WITH THE SYSTEM’S TECHNICAL DOCUMENTATION!

CONTENTS:

INTRODUCTION

1.0 MANUFACTURING BASIS

2.0

OPERATING MANUAL

2.1

TERMINOLOGY AND DEFINITIONS

2.2

PURPOSE AND SCOPE OF USAGE

2.3

TECHNICAL SPECIFICATION AND THE CONSTRUCTION OF THE SYSTEM

2.3.1

TECHNICAL SPECIFICATION –INTERMEDIATE BARRIER

2.3.2

TECHNICAL SPECIFICATION –TOE BOARD

2.3.3

TECHNICAL SPECIFICATION –MAIN RAILING

2.3.4

TECHNICAL SPECIFICATION –POLES

2.3.5

TECHNICAL SPECIFICATION –FILLING (INTERMEDIATE BARRIER)

2.3.6

TECHNICAL SPECIFICATION –HOLDERS

2.3.7

TECHNICAL SPECIFICATION –ADAPTERS

2.3.8

TECHNICAL SPECIFICATION –UNIVERSAL FLOOR CLAMP

2.3.9

TECHNICAL SPECIFICATION –FORMWORK CONSOLES

2.4

SYSTEM'S ELEMENTS’DIMENSIONS

2.5

USAGE

2.6

ASSEMBLY OF THE EDGE PROTECTION SYSTEM

2.7

DISASSEMBLING AND MOVING THE DEVICE BETWEEN WORKPLACES

2.8

RULES FOR SAFE OPERATION

3.0

SYSTEM'S CHECK

3.1

MAINTENANCE

4.0 DEVICE’S REGISTER

5.0 RATING PLATE

6.0

7.0 DESIGNER’S STATEMENT

EU DECLARATION OF CONFORMITY

P a g e | 3

INTRODUCTION

This technical documentation contains the guidelines concerning the proper use of THE EDGE

PROTECTION SYSTEM. Workers and other people using the system shall always observe the

guidelines contained herein. In case of any events not described in this document, the occupational

safety and health regulations and other regulations, appropriate to the specific situation, shall be

observed.

It is forbidden to modify the system in any other way than described in the Technical

Documentation. The manufacturer is not liable for any modifications in the system in a way

that is not described in the technical documentation.

1. MANUFACTURING BASIS

THE EDGE PROTECTION SYSTEM is aimed at increasing the safety of works performed at heights.

The project of the edge protection system was prepared in accordance with the current laws

and technical standards:

EN-13374 –Temporary edge protection system

+A1_2019-02E

EN 1090 –Technical requirements for the execution of steel and aluminium structures.

PN-EN ISO 3834-2 –Quality requirements for the welding of

metal materials

P a g e | 4

2.0

OPERATING MANUAL

2.1

TERMINOLOGY AND DEFINITIONS

The edge protection system:

A set of elements used to protect workers from a fall and to catch falling materials.

Main railing:

A railing or an element which makes the upper edge / surface of the edge protection

system.

A protection / intermediate barrier:

A protecting barrier (made of a net or a set of other elements) between the main railing and

a working surface.

A toe board:

A standing / vertical element used to stop materials and protect people from falling or

sliding down from the working surface.

A pole:

The main element of the edge protection system to which the main railing and the toe board

are assembled.

A holder:

An element used to assemble the pole to a given working surface.

The height of the edge protection system:

The distance from the highest point of the main railing to the working surface, measured

perpendicularly to the working surface.

A working surface:

The surface on which a worker stands, walks or works.

P a g e | 5

2.2

PURPOSE AND SCOPE OF USAGE

The edge protection system is aimed at securing the outer edges of buildings and used as a

protection measure while performing works on lower levels and to secure communication strings.

The edge protection system is used while performing constructional works for, primarily, protecting

and preventing from the falls of people an objects onto the lower working levels. The protection

system encompasses areas near the floor's edge and other areas that demand protection.

The EN-13374+A1_2019-02E standard defines three security areas between the floor and the

ceiling;

Ca1 (from the floor to min. 1 m above the floor), Ca2 (from 1 m to 2

m above the floor),

Ca3 (from 2 m to the ceiling).

This definition includes in particular the security range of the Ca1 area.

The protection system (for all three classes: Ca1, Ca2 and Ca3) was also designed on the

basis of the requirements concerning the protection from objects carrier by wind (EN-

13374+A1_2019-02E, point 6.3.4).

The system was designed on the basis of the “Class A” requirements, described in the

5.2.1 of the abovementioned standard.

The system is characterised by an easy, universal and quick assembly to the front and the upper part

of a floor, as well as to a wall. Thanks to the lightness and flexibility of the system, it is possible to

adjust it to all building conditions.

The edge protection system is an affordable and quick way to secure working areas where there is

the need to increase the level of safety.

The use of the edge protection system is allowed only on condition that the user adheres to this

Technical Documentation, as well as the proper occupational safety and health regulations.

P a g e | 6

2.3

TECHNICAL CHARACTERISTICS AND CONSTRUCTION OF THE SYSTEM

The edge protection system is a steel construction (or metal-wooden) consisting of three main parts: an

assembly holder, a pole and an intermediate barrier.

The intermediate barrier can be set in three different options, e.g. as horizontal balk, a steel panel net or a

polypropylene net with an edge line.

The system's module consists of a pole with a holder and a proper barrier, according the above

description.

Each module of the system contains also optional holders or adapters for different assemblies, e.g.

upper assembly, side assembly, assembly to stairs etc.

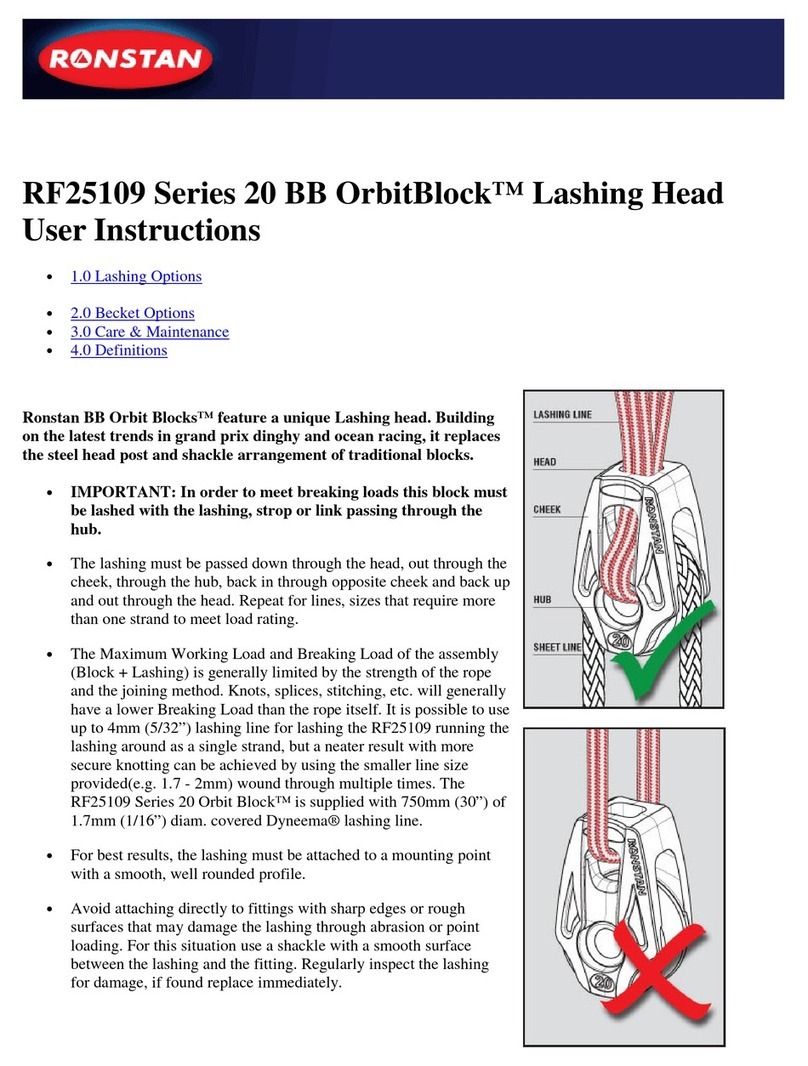

TOE BOARD HOLDER

INTERMEDIATE BARRIER

MAIN RAILING

TOE

BOARD

POLE

P a g e | 7

2.3.1

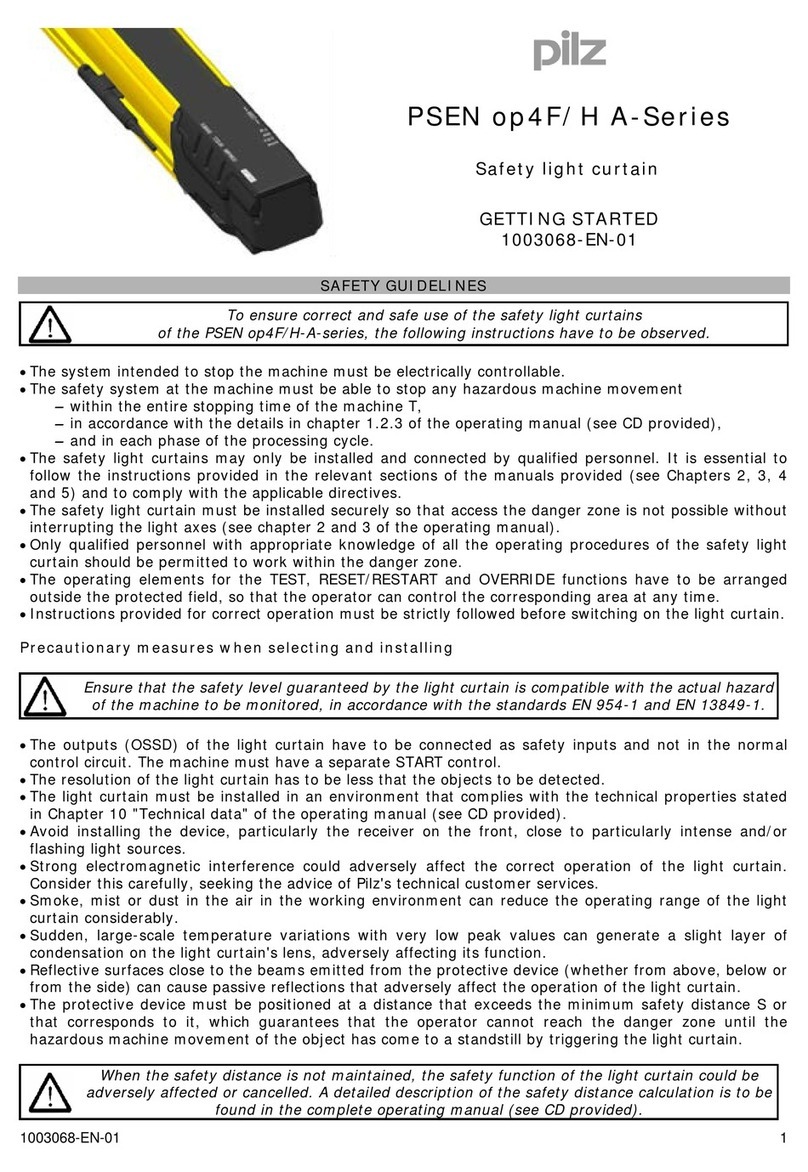

TECHNICAL SPECIFICATION –INTERMEDIATE BARRIER

The intermediate barrier of the Ca1 protection area is defined by the EN-

13374+A1_2019-02E standard in point 4

(Defined load classes A-static loads, B-static loads and low episodic dynamic loads, C-static loads and high

dynamic loads connected to sliding down of people and objects)

And in point 5.2, see Appendix No. 1.

The intermediate barrier of the edge protection system is also defined by such parameters, as the

“mesh density” in the “containment porosity Cp” and the wind class” Cq.

The elements of the intermediate barrier are periodically checked for its wear and suitability for the

use in a safety system. The check is performed by the manufacturer or an authorized body.

PVC MESH –1 mm, H 1.2 mPOLYPROPYLENE MESH Ø5 – H 1.2 m

BALK 32 mm –15 × 250 cmPANEL MESH Ø5 – 2.5 × 1.2 m

P a g e | 8

2.3.2

TECHNICAL SPECIFICATION –TOE BOARD

A standing / vertical element used to protect materials and people from falling or sliding down

from the working surface.

The toe board shall provide the security for the area at the height of 1 cm from the working

surface (measured perpendicularly to that surface)

Its maximum lift towards the working surface equals 2 cm.

TOE BOARD 15 cm

TOE BOARD 15 cm

P a g e | 9

2.3.3

TECHNICAL SPECIFICATION –MAIN RAILING

A railing or an element which makes the upper edge / surface of the edge protection

system.

The distance between the highest railing point and the working level cannot be smaller than 1000

mm (measured perpendicularly to the working surface).

MAIN RAILING

MAIN RAILING

2.3.4 TECHNICAL SPECIFICATION –POLES

Cat. No.: 5160 CLAMPING POLE KBW

Cat. No.: 5150 BARRICADE POLE

Cat. No.: 5140 SINGLE POLE

Cat. No.: 5120 STANDARD POLE

Cat. No.: 5130 LITE POLE

Cat. No.: 5110 H POLE

P a g e | 10

2.3.4 TECHNICAL SPECIFICATION –POLES

P a g e | 11

H POLE –Cat. No.: 5110 –with the height of 120 cm, it is used to prepare a safety barrier with a mesh

filling and a boarding. It can be used for a few types of holders that can be assembled to different surfaces

in different positions.

The pole is locked in a socket by rotating and placing in a working position towards the floor.

It is used to work with horizontal and vertical holders, 500 and 250 adapters, a holder for a

girder, Larsen, a floor clamp and a rammed holder.

LITE POLE –Cat. No.: 5130 –with the height of 120 cm, it is used to prepare a safety barrier

with a mesh filling and a boarding. It can be used for a few types of holders that can be

assembled to different surfaces in different positions.

It is equipped with a self-locking socket of the net.

The pole is locked in a socket by rotating and placing in a working position towards the floor.

It is used to work with horizontal and vertical holders, 500 and 250 adapters, a holder for a

girder, Larsen, a floor clamp and a rammed holder.

STANDARD POLE –Cat. No.: 5120 –with the height of 120 cm, it is used to prepare a safety barrier

with a mesh filling and a boarding. It can be used for a few types of holders that can be assembled to

different surfaces in different positions.

The pole is locked in a socket by rotating and placing in a working position towards the floor.

It is used to work with horizontal and vertical holders, 500 and 250 adapters, a holder for a

girder, Larsen, a floor clamp and a rammed holder.

SINGLE POLE –Cat. No.: 5140 –with the height of 120 cm, it is used to prepare a safety barrier

with a mesh filling and a boarding. It is intended for the assembly in a concrete surface with the

screws for concrete or assembly anchors.

It allows to quickly, easily and cheaply assemble the protective barrier.

BARRICADE POLE –Cat. No.: 5150 –with the height of 120 cm, it is used to prepare a safety barrier with

a mesh filling and a boarding. It is used at construction sites during renovation works, while performing

roadworks and to secure digging deep trenches. An example of usage is separating the area where works

which may cause the risk of potential accident, i.e. falling from height, dangerous wetland etc., are

performed.

CLAMPING POLE KBW –Cat. No.: 5160 –with the height of 120 cm, it is used to prepare a safety barrier

with a mesh filling and a boarding. The pole can be assembled at the edge of the floor by twisting the

lower clamping jaw. Such type of assembly can also be used in case of girders that are placed below the

floor. Thanks to the height of the pole, which is 180 cm, the users can secure the upper level to the min.

required height of 1 m. The maximum jaw’s offset is 50 cm.

The poles are made of constructional steel and are galvanized.

P a g e | 12

2.3.5

TECHNICAL SPECIFICATION –FILLING (INTERMEDIATE BARRIER)

Cat. No.: 5440 MESHWALL NET

Cat. No.: 5430 BARRICADE NET

Cat. No.: 5410 BALK 250 cm

Cat. No.: 5420 MESH PANEL 250 cm

Cat. No.: 5450 MESH PANEL 130 cm

P a g e | 13

2.3.5

TECHNICAL SPECIFICATION –FILLING (INTERMEDIATE BARRIER)

MESH PANEL 250/130 cm –Cat. No.: 5420/5450 –is made of a welded, galvanised net which

consists of three protective areas:

-

upper “shelf” (width = 12 cm) used as a supinated grip.

-

the vertical filling up to the height of 120 cm over the working surface,

-

full steel toe board (height = 12 cm).

The vertical poles are placed differently within the range of 10–20 cm, the oblique placement of the toe

board allows to stop smaller objects (e.g. hardcore) from accidental falling out of the working area.

EPS BALK 250 cm –Cat. No.: 5410 –the intermediate barrier consists of three levels (2500 × 150

× 32 balk).

It protects from falling through the edge of the working level. It is assembled in the H pole holders,

Standard and Single.

The lower balk is a protection –toe board which catches smaller objects accidentally falling from the

working level.

BARRICADE NET –Cat. No.: 5430 –is a barrier made as a non-flexible PVC net. Its main advantage is low

weight, easy assembly procedure, resistance to the weather conditions and universality.

The system is used at construction sites, during renovation works, roadworks and while digging deeper

trenches. It is a warning barrier, informing people about a dangerous area. The poles of the barrier

are made of constructional and galvanised steel.

MESHWALL NET –Cat. No.: 5440 –is a protective barrier made as a polypropylene net. Its main advantage

is low weight, easy assembly procedure and resistance to the weather conditions.

The MESHWALL barrier consists of poles, e.g. LITE, a net and an edge line which works as a supinated

grip and an element stretching the whole system.

The net is manufactured in accordance with the edge protection systems and fall arrest systems (safety

nets) standards.

P a g e | 14

2.3.6

TECHNICAL SPECIFICATION –HOLDERS

Cat. No.: 5280 TOE BOARD HOLDER

Cat. No.: 5210 VERTICAL HOLDER

Cat. No.: 5220 HORIZONTAL HOLDER

Cat. No.: 5270 PLATFORM HOLDER

Cat. No.: 5250 LARSEN HOLDER

Cat. No.: 5240 GIRDER HOLDER

Cat. No.: 5260

WALL HOLDER

Cat. No.: 5230

RAMMED HOLDER

Cat. No.: 5290

ATTIC HOLDER

P a g e | 15

2.3.6

TECHNICAL SPECIFICATION –HOLDERS

HORIZONTAL HOLDER –Cat. No.: 5220 –is used to assemble poles to a moveable surface. It is adjusted to

be assembled in a vertical position to the ground with screws for concrete or mechanical anchors. The

holder has a socket with a blockade that is used to lock the pole and protect it from accidentally taking

out. The horizontal holder contains the toe board holder used in case of using a net or boarding.

VERTICAL HOLDER –Cat. No.: 5210 –is used to assemble poles to a working surface. It is adjusted to

be assembled in a vertical position to the ground with screws for concrete or mechanical anchors.

The holder has a socket with a blockade that is used to lock the pole and protect it from accidentally

taking out. The holder contains also a toe board holder used in case of a connection to the extending

adapter 500/250. It is also used to block the net of prepare a toe board on the level of the pole or the

extending adapter.

TOE BOARD HOLDER –Cat. No.: 5280 –is used to assemble the balk (toe board) or mesh panels on

holders: horizontal, vertical, on girder, on Larsen, rammed and on attic holders.

GIRDER HOLDER –Cat. No.: 5240 –is used to prepare the protective barrier on formwork. Its main advantage

is the speed and simplicity of assembly, it does not require using power tools, anchors etc. The assembly is

limited only to placing an open clamp on the formwork and clenching it with a hammer by ramming a

wedge into the clamp’s socket. With the use of the 500/250 height adapter, in an easy way the workers

may lift the barrier to the level ensuring safety and compliance with standards. It is used during the

preparation of the concrete floor what leads to lifting the working level (while lowering the height of the

protection that was earlier provided on formwork).

LARSEN HOLDER –Cat. No.: 5250 –is used to prepare a protective barrier sheet piles. Its main advantage

is the simplicity of assembly and disassembly. It is limited to tightening the locking screw. A low

weight and the ease of storing and transport are another advantages of that system's element. The

LARSEN holder has a socket with a blockade that allows the lock the pole and secure it from an

accidental taking out.

PLATFORM HOLDER –Cat. No.: 5270 –is used to create working bridges, e.g. in shafts or any niches

where there is the need to create a temporary bridge. The holder is used with wooden balks of 10 cm

width. The assembly to the wall is performed through the Ø16 diameter slot.

ATTIC HOLDER –Cat. No.: 5290 –is used to assembly the poles to the walls and allows to move the

barrier towards and away from the wall. Thanks to this solution the user may adjust the barrier to given

constructional elements i.e. attic etc. The vertical adjustment scope is 34 cm. The height (active) of the

socket is 30 cm –is it the distance to which the holder can be lowered in relation to the working

surface, so that the barrier will keep the 120 cm height. If there is the need to further lower the

holder, the 250/500 adapters shall be used.

P a g e | 16

WALL HOLDER –Cat. No.: 5260 –is used to prepare a barrier assembled directly to the walls (i.e.

protection of window openings, doors etc.). It can be used with formwork and mesh panels.

RAMMED HOLDER –Cat. No.: 5230 –is used to prepare a protective barrier in any surface which allows

to assemble the anchor to the rammed holder. The surface must provide the stability of the barrier

pole, so that it will not deviate from the vertical position due to the influence of the weather conditions.

The holder has a socket with a blockade used to lock it and secure from an accidental taking out.

2.3.7

TECHNICAL SPECIFICATION –ADAPTERS

Cat. No.: 5320 ADAPTER 500

Cat. No.: 5310 ADAPTER 250

EXTENDING ADAPTERS 250/500 –Cat. No.: 5310/5320 –is used to lift the pole of the protective barrier

in case of an assembly e.g. of the vertical holders (where there is the lowering of the barrier in relation to

the working surface). When there is such need, the height adapter allows to lift the protection by

250/500 mm. The adapter has a lower locking socket which works with the holder and an upper socket

working with the pole's socket. The sockets are locking each other what protects from an accidental

taking out. The extending adapters are also useful while preparing barriers on girder or Larsen holders.

In case of lifting the working surface (e.g. concrete floor) they lift the barrier to the level providing safety

and compliance with standards.

The holders and adapters are made of constructional steel and are galvanised.

P a g e | 17

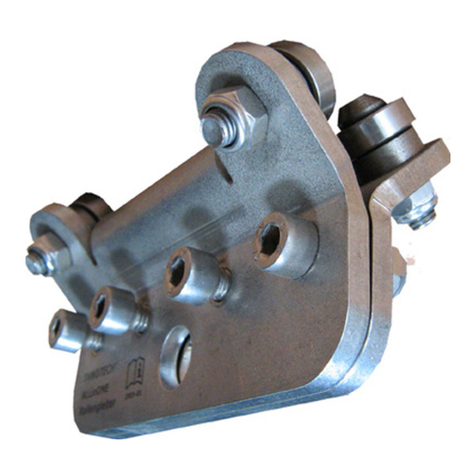

2.3.8

TECHNICAL SPECIFICATION –UNIVERSAL FLOOR CLAMP

FLOOR CLAMP Cat. No.: 5510 consist of:

1.

A lower arm

2.

An upper arm (moveable)

3.

A head (moveable)

4.

A pressing screw

5.

A pressing nut

The clamp is characterized by two types of arm

spacing: narrow and wide.

Based on the assembly needs, the user can configure the

clamp’s elements. The upper arm shall be rotated to the

normal position and turned upside down (180 degrees).

The moveable head shall be adjusted to the

assembled upper holder.

The head shall be place in a normal or turned by

180 degrees position in order to adjust it to the

moveable arm’s socket (see the figure.)

….. The upper arm shall be rotated to

the normal position and turned upside

down (180 degrees)……..

….. The head shall be place in a

normal or turned by 180

degrees……..

4.

2.

3.

5.

WIDE SPREAD

NARROW

SPREAD

1.

2.3.8

TECHNICAL SPECIFICATION –UNIVERSAL FLOOR CLAMP

| 18

P a g e

….. The clamp is characterized by two

types of arm spacing: narrow and wide…….

The maximum spacing 52 cm The

minimum spacing: 9 cm

UNIVERSAL FLOOR CLAMP –STAIRWAYS CONFIGURATION

….. Thanks to a moveable head it adjusts

to the shape of stairs and the soffit …….

The clamp can be adjusted to the flight of stairs.

Thanks to a moveable head it adjusts to the shape

of stairs and the soffit of each flight of stairs.

The head turns freely around the upper arm's

socket, thanks to what it automatically adjusts to a

given shape.

P a g e | 19

UNIVERSAL FLOOR CLAMP –HORIZONTAL CONFIGURATION

The socket is available in horizontal configuration,

adjusted to ledges etc. The pole is assembled to optional

sockets that are placed in the upper and lower arm.

LOWER ARM’S SOCKET

UPEPR ARM'S SOCKET

P a g e | 20

2.3.9 TECHNICAL SPECIFICATION –FORMWORK CONSOLES

THE FIXED AND MOVEABLE CONSOLES are used in the preparation of security measures on the walls’ edges which are

used to prepare formwork. The are also used as a formwork element (to assemble the formwork balk), so they

are a universal solution used in constructional works and increasing the level of safety of the works performed.

This solution uses the holes in walls made during the preparation of formwork.

The solution helps to save time on assembling the protection (no need to drill holes, anchoring etc.).

THE MOVEABLE CONSOLE is an extension of the fixed console when there was used the possibility to move the

formwork balk from the wall.

Cat. No.: 5610 FIXED CONSOLE

Cat. No.: 5620 MOVEABLE CONSOLE

Table of contents

Other STRUMIN Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Summit Treestands

Summit Treestands Seat-O-The Pants Series instructions

Duct-O-Wire

Duct-O-Wire RPB Series quick start guide

MTM HYDRO

MTM HYDRO 14.0349 user manual

CanaSafe

CanaSafe TiGer manual

Ronstan

Ronstan BB OrbitBlock RF25109 Series User instructions

Daikin

Daikin VRV 5 Installation and operation manual